Wrist rehabilitation device

A rehabilitation device and wrist technology, applied in the field of medical equipment, can solve problems such as wrist injury, no prompt function or means, and no clear evaluation of the effect of patient exercise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The following is attached Figure 1-6 The present invention is described in further detail.

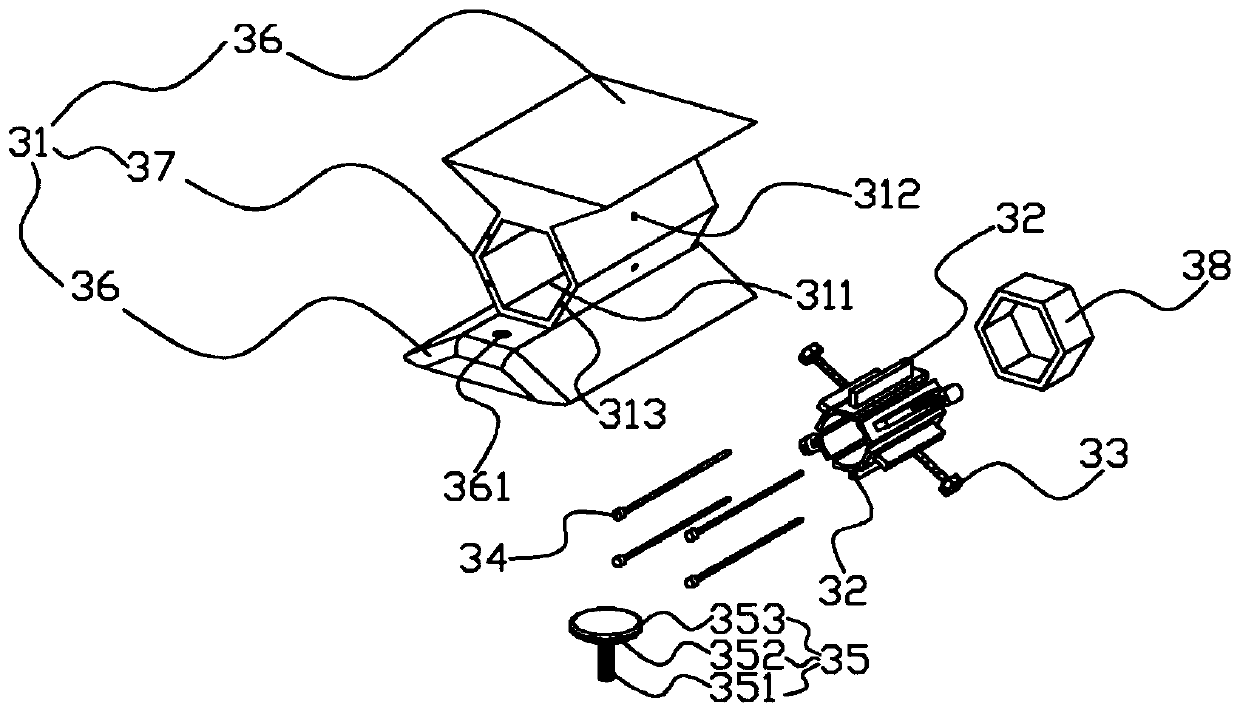

[0041] A wrist rehabilitation device such as figure 1 As shown, it includes a fixed table 1, a swivel chair 2, two forearm fixing parts 3, two docking parts 4, two warning parts 5 and two wrist exercise parts 6, the fixed table 1 is fixed on the ground, and the swivel chair 2 is placed on a fixed One end of the table 1, two forearm fixing parts 3 are symmetrically arranged on the desktop of the fixed table 1 near the end of the swivel chair 2, two docking parts 4 are symmetrically arranged on the desktop of the fixed table 1 away from the end of the swivel chair 2, and the two forearms The fixing part 3 is in one-to-one correspondence with the two docking parts 4, and the two warning parts 5 are respectively connected to two sets of corresponding forearm fixing parts 3 and the docking parts 4, and one end of the two wrist training parts 6 is respectively set on different docki...

Embodiment 2

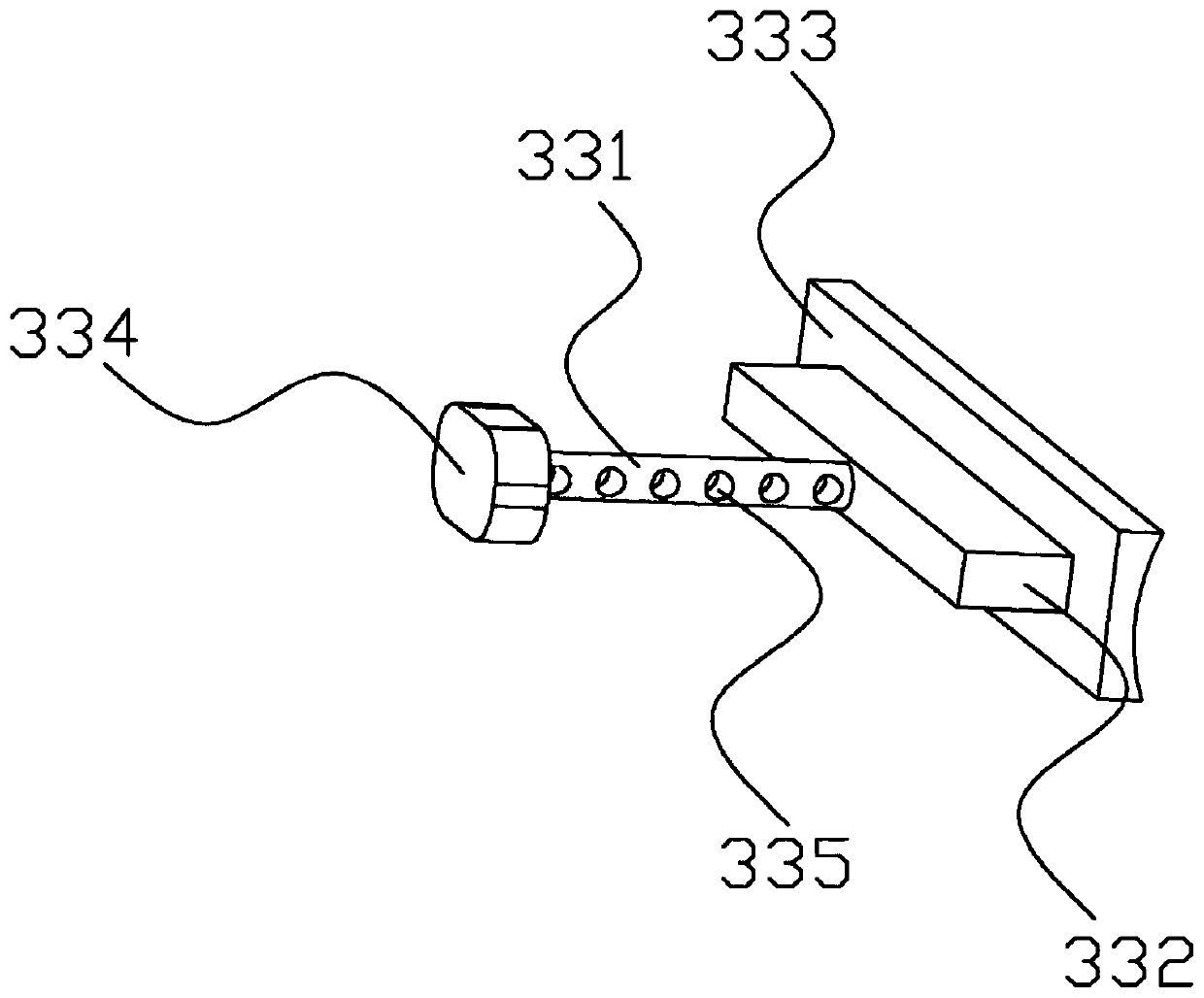

[0059] The difference from Example 1 is that the adjusting rod 331 is coated with a wear-resistant layer, and the preparation method of the wear-resistant layer is as follows:

[0060] Get the following components by weight for subsequent use: 5 parts of quartz powder, 8 parts of chromium powder, 6 parts of diatomaceous earth, 20 parts of molybdenum powder, 11 parts of thermoplastic water-based polyurethane, 3 parts of ethylene oxide, 39 parts of cobalt powder, 10 parts of sodium bentonite, 2 parts of furfural resin and 70 parts of ethanol.

[0061] S1. Prefabricated organic solvent: After mixing thermoplastic water-based polyurethane, ethylene oxide, furfural resin and ethanol, stir evenly;

[0062] S2. Preparation of wear-resistant material: add quartz powder, chromium powder, diatomite, molybdenum powder, cobalt powder and sodium bentonite to the organic solvent in S1, stir evenly, heat the temperature to 75° C. and keep it warm for 4 hours;

[0063] S3. Cleaning: Clean an...

Embodiment 3

[0068] The difference from Example 2 is that the formula specific gravity of the wear-resistant layer is modified, and the modified preparation method is:

[0069] Get the following components by weight for subsequent use: 7 parts of quartz powder, 11 parts of chromium powder, 8 parts of diatomaceous earth, 22 parts of molybdenum powder, 15 parts of thermoplastic water-based polyurethane, 4 parts of ethylene oxide, 42 parts of cobalt powder, 15 parts of sodium bentonite, 4 parts of furfural resin and 80 parts of ethanol.

[0070] S1. Prefabricated organic solvent: After mixing thermoplastic water-based polyurethane, ethylene oxide, furfural resin and ethanol, stir evenly;

[0071] S2. Preparation of wear-resistant material: add quartz powder, chromium powder, diatomite, molybdenum powder, cobalt powder and sodium bentonite to the organic solvent in S1, stir evenly, heat the temperature to 75° C. and keep it warm for 4 hours;

[0072] S3. Cleaning: Clean and decontaminate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com