Layered duck breeding method

A stacked duck cage technology, applied in the poultry industry, application, poultry cages or houses, etc., can solve the problems of large space occupation, unfavorable cost control, large excrement, etc., to achieve easy water replenishment and feed, effective Conducive to safe collection and satisfying the effect of free feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

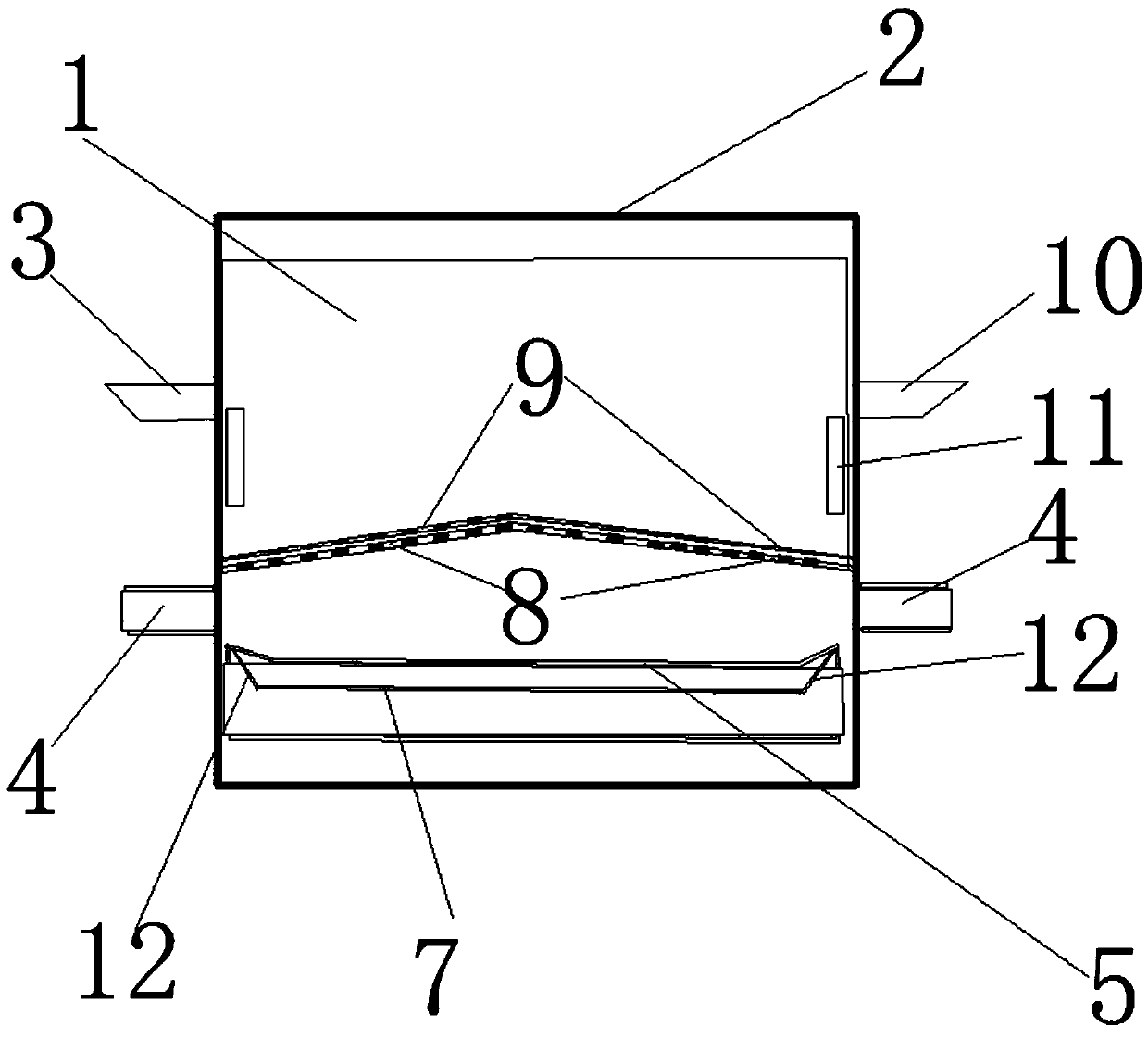

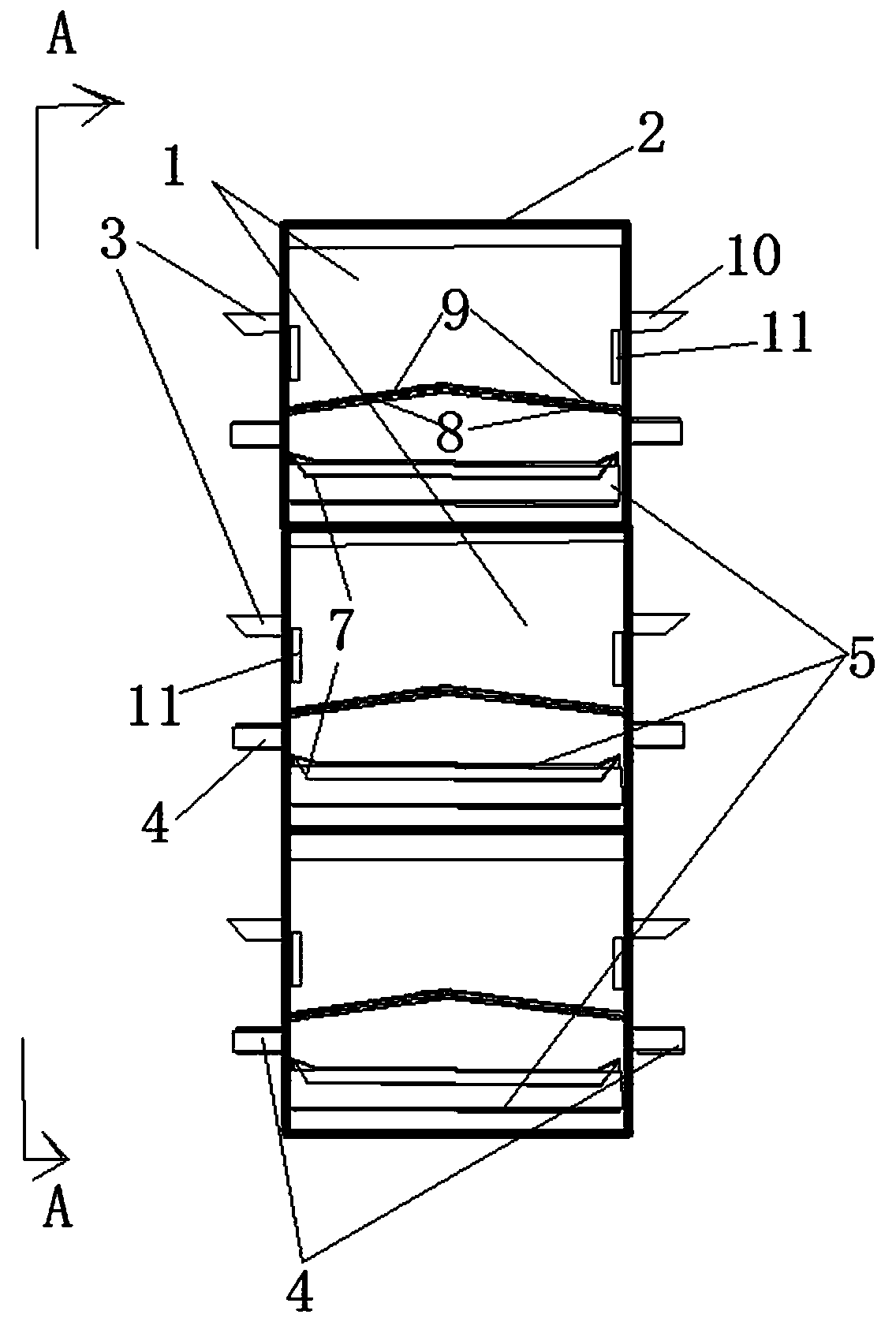

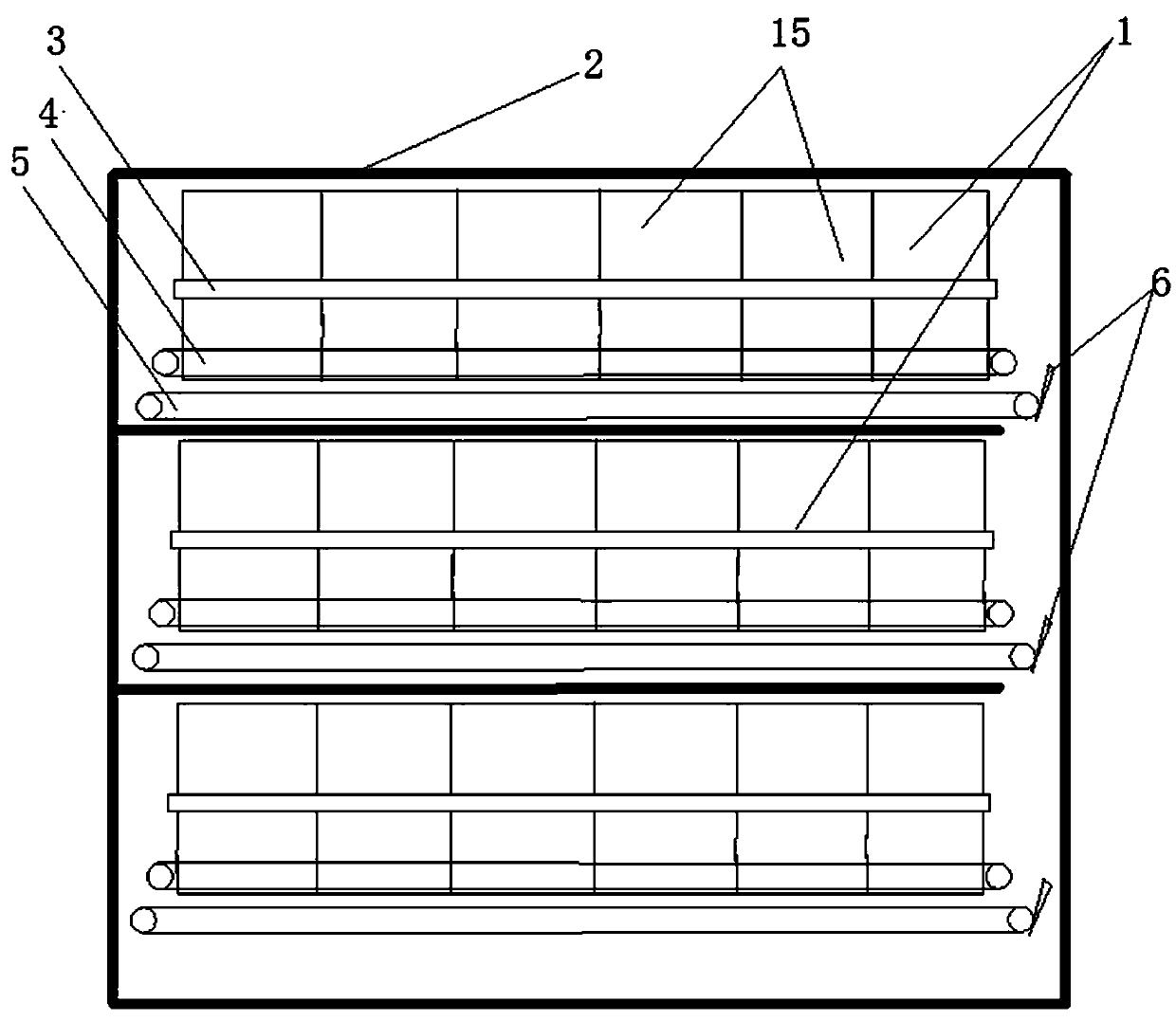

[0041] In this example, the duck cages on the same floor of the frame share the feces and urine collection conveyor belt 5, and the excrement of the laying ducks leaks directly from the egg collection mesh to the feces and urine collection conveyor belt 5, and the laying ducks are cleaned by combing their feathers after drinking water. The debris and water also flow to the excrement collection conveyor belt 5, because the bottom of the duck cage is provided with conveyor belt support bars 7 at intervals along the excrement collection conveyor belt conveying direction, the two ends of the conveyor belt support bars 7 are upturned to The both sides of the conveying surface supporting the excrement and urine conveyor belt 5 form a U-shaped conveying surface, so the duck excrement on the excrement and urine conveying belt 5 can be concentrated on the conveyor belt conveying surface without lateral flow, and when the cleaning time is reached, the collecting The feces and urine conve...

Embodiment 2

[0043] In this example, the duck cages on the same floor of the frame share a water tank and a feeding trough; the laying ducks 13 on the same floor can directly protrude their heads from the railing gap of the side wall of the duck cage to drink water in the same water tank. The amount is very large, when the water level in the water tank dropped to the threshold value, the floating ball of the automatic water replenishment device 14 descended to open the water pipe outlet, replenished water to the water tank, and when the water level of the water tank rose to the threshold value, the floating ball of the automatic water replenishment device 14 (contacted with the water surface) Spherical floating body) rises to block the outlet of the water pipe, stop replenishing water to prevent the tank from overflowing.

[0044] Since the water tank is horizontally fixed on the rack, the long and narrow water tank can simulate a river in a stocking environment, allowing the ducks to drink...

Embodiment 3

[0046] After the laying duck lays eggs, the duck eggs roll along the slope of the egg-collecting mesh 8 from the gap between the railings at the bottom of the duck cage wall to the egg-collecting conveyor belt; Duck paws can be damaged, so as to maintain the activity of laying ducks in the cage environment and promote the health of caged laying ducks. When the laying ducks are actively moving, even if the slope of the egg-collecting mesh 8 is small, the laying ducks can also move. Pull the duck eggs off the egg-collecting conveyor belt, so a small-slope egg-collecting mesh can be used in the duck cage to prevent the duck eggs from being damaged due to rapid rolling.

[0047] The eggs that arrive at the egg collection conveyor belt stay on the conveyor surface. When the egg collection time is up, the egg collection conveyor belt starts to transfer the eggs on the conveyor surface to the next process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com