A method and system for extracting weld contour

A contour and image technology, applied in the field of image processing, can solve the problems of lack of automaticity in parameter selection and no specific solution proposed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

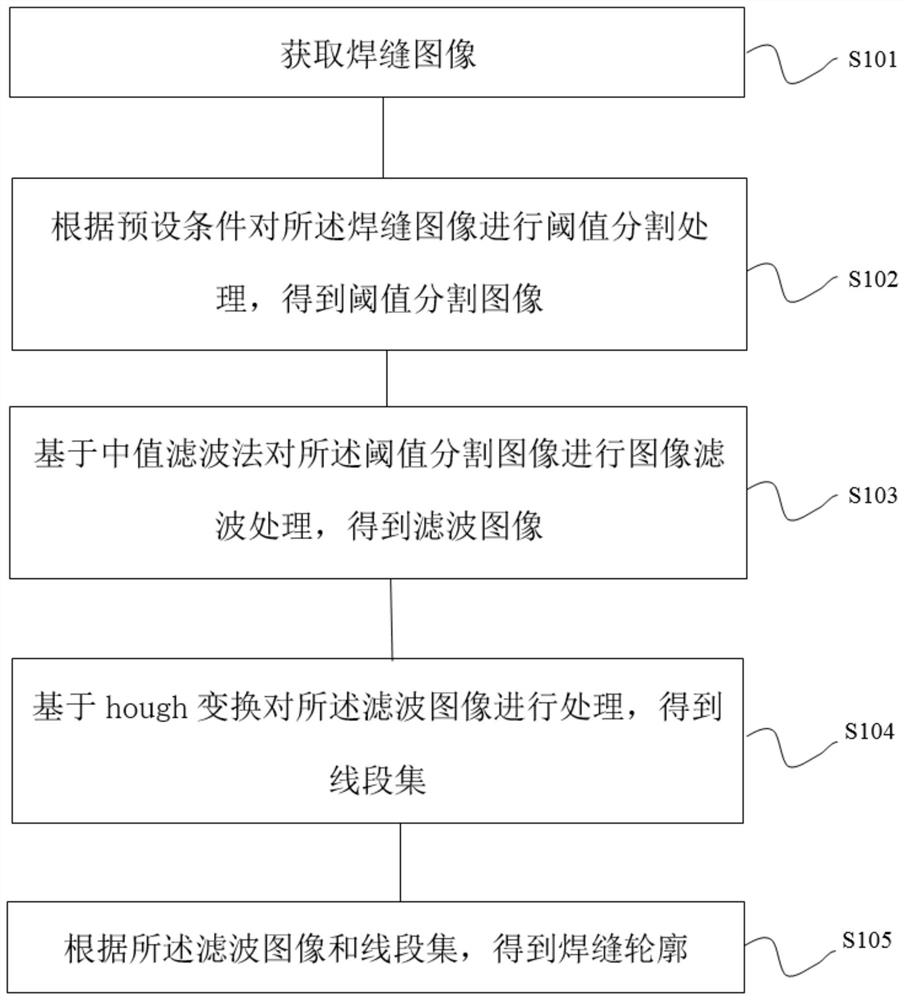

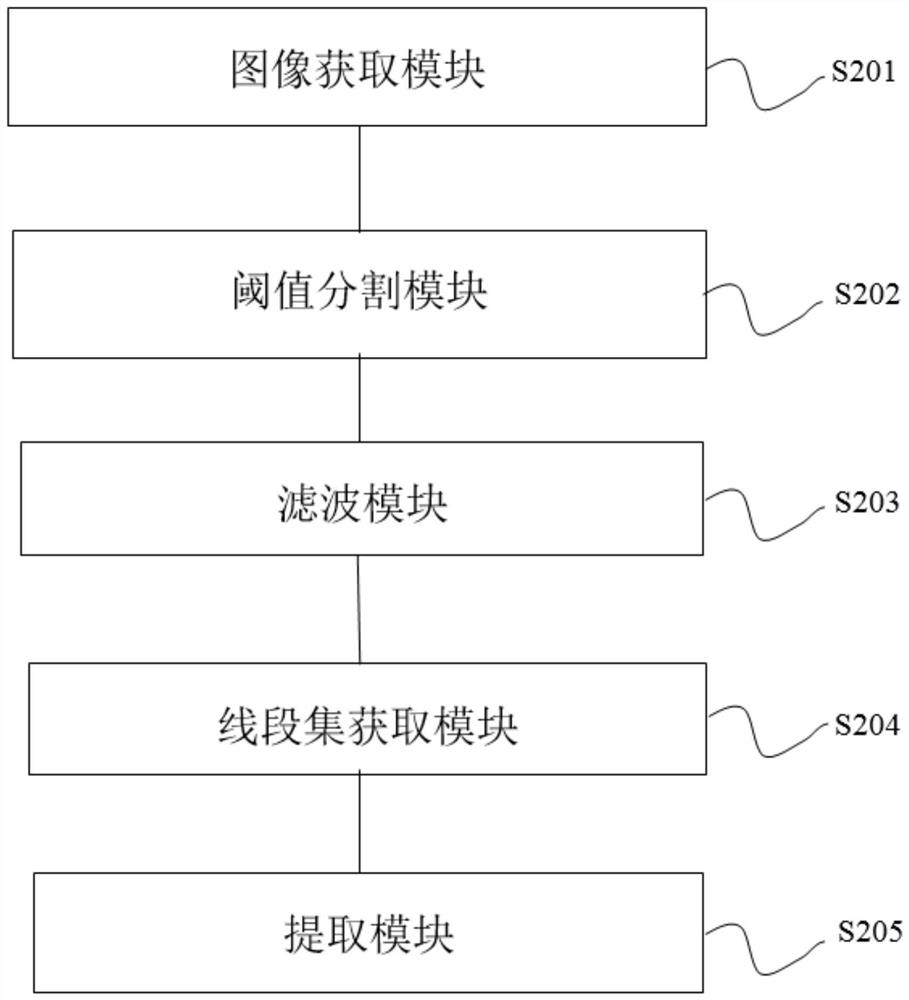

[0024] Embodiment one: refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , this embodiment provides a method for weld contour processing, such as figure 1 shown, including the following steps:

[0025] Step S101: Acquiring weld seam images;

[0026] Step S102: Perform threshold segmentation processing on the weld seam image according to preset conditions to obtain a threshold segmentation image;

[0027] Step S103: performing image filtering on the threshold segmented image based on a median filter method to obtain a filtered image;

[0028] Step S104: Process the filtered image based on the hough transform method to obtain a line segment set;

[0029] Step S105: According to the filter image and the line segment set, obtain the outline of the weld seam.

[0030] Wherein, performing threshold segmentation processing on the weld image according to preset conditions to obtain the threshold segmentation image includes: storing the acquired weld...

Embodiment 2

[0039] Embodiment two: refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , this embodiment provides a method for weld contour processing, such as figure 1 shown, including the following steps:

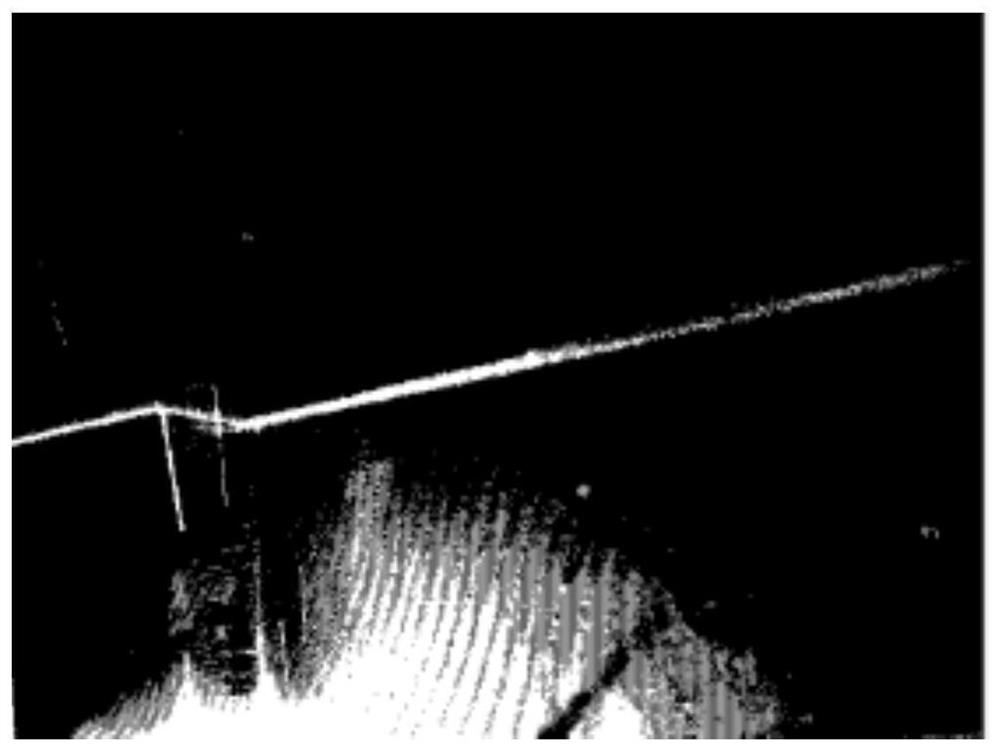

[0040] Step S101: Obtain a weld seam image. The weld seam image is an image including the weld seam in the welding process. In practical applications, the processing system can receive and obtain it through the image collector, or obtain it through data transmission through connection with the outside world. In the application scenario, in the robot welding system The welding seam identification or seam tracking is based on the premise of effectively extracting the seam contour information.

[0041] Step S102: Perform threshold segmentation processing on the weld seam image according to preset conditions to obtain a threshold segmentation image. The obtained weld seam image is stored in a preset current image stack, and when the stack is full, thresho...

Embodiment 3

[0087] Embodiment three: refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , this embodiment provides a method for weld contour processing, such as figure 1 shown, including the following steps:

[0088] Step S101: Obtain a weld seam image. The weld seam image is an image including the weld seam in the welding process. In practical applications, the processing system can receive and obtain it through the image collector, or obtain it through data transmission through connection with the outside world. In the application scenario, in the robot welding system The welding seam identification or seam tracking is based on the premise of effectively extracting the seam contour information. Compared with the two situations of welding seam image acquisition in the prior art: first, the image is collected under the condition of no arcing, does not contain molten pool information, and thus the image has less noise; second, the selection of algorithm par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com