TBM slag sheet ray back scattering real-time scanning imaging device and method

A scanning imaging and backscattering technology, which is applied to measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve the problems of cumbersome procedures, long time-consuming, low efficiency, etc., to improve the working environment, ensure personnel safety, Effects of Avoiding Radiation Leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

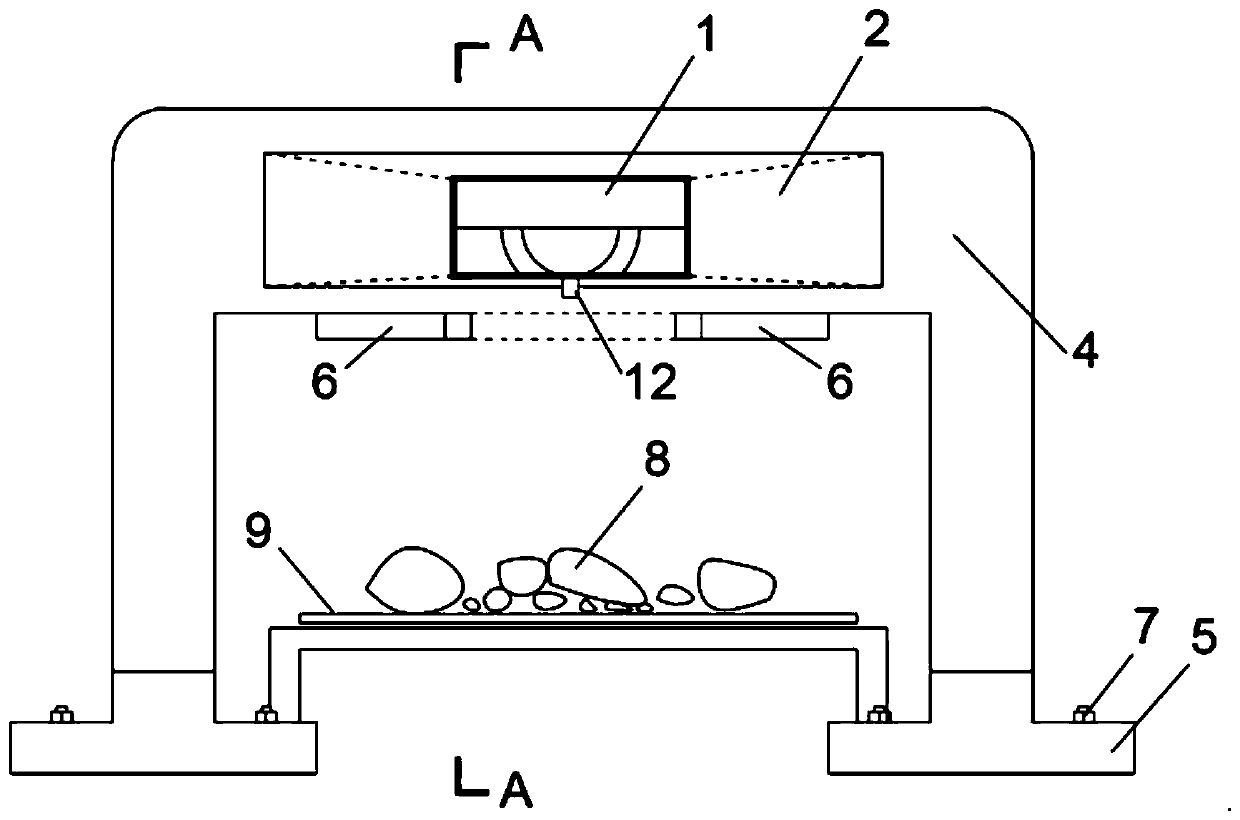

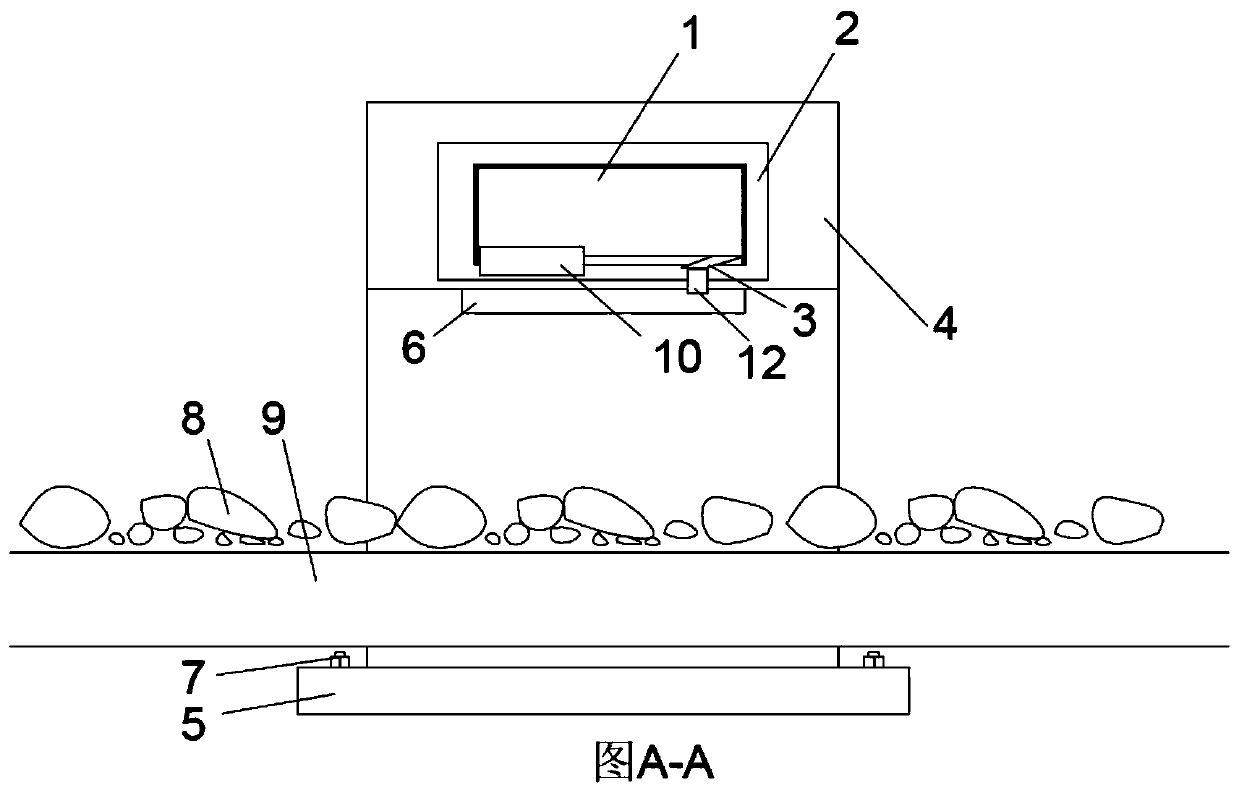

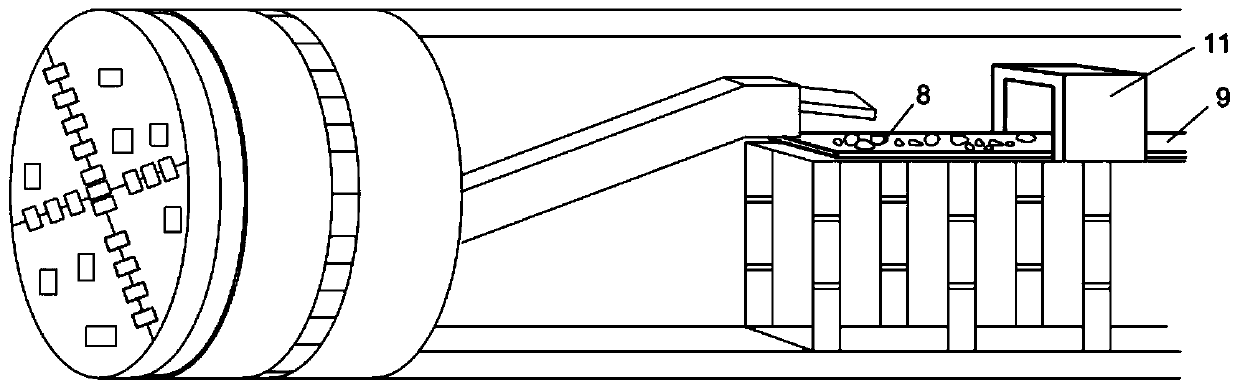

[0042] In a typical embodiment of the present invention, such as Figure 1-Figure 3As shown, a TBM slag slag ray backscatter real-time scanning imaging device 11 includes a bracket 4 that can be arranged across a TBM conveyor belt 9 for transporting slag chips 8 .

[0043] The TBM conveyor belt 9 has a set length, and the TBM conveyor belt 9 is supported by a pillar, so that the TBM conveyor belt 9 has a set height. The bottom of the support 5 is supported by a pillar, and the bottom of the pillar is arranged on the ground, and the fixed support 5 is connected with the support 4 through bolts.

[0044] In some embodiments, in order to realize that the support 4 drives the movement of the radiation-proof housing 2 relative to the fixed support 5, a slider is provided at the bottom of the support 4, and a slide rail is provided at the fixed support 5, and the slide block cooperates with the slide rail to realize radiation protection. The movement of the shell 2 relative to the ...

Embodiment 2

[0052] A kind of TBM slag sheet ray backscatter real-time scanning imaging analysis method, adopts a kind of TBM slag sheet ray backscatter real-time scanning imaging device described in embodiment 1, comprises the following contents:

[0053] When starting to scan, open the slide switch door 6, again as figure 2 As shown in , the X-ray tube 3 and the detection receiver 10 are arranged along the transmission direction of the belt conveyor at one time. As the TBM conveyor belt moves, the X-ray tube 3 is excited, and the detection receiver 10 receives the corresponding number of Compton scattered photons from different positions , X-ray backscattering can carry out large-area and single-sided scanning, because there is no limitation of post-part imaging equipment, and it is convenient for mobile scanning, small in size and small in working space. It is very consistent, and the device is real-time, and can feed back the scanning results to the TBM driver in a relatively short pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com