Self-locking device of linear actuator and linear actuator

A technology of linear actuator and self-locking device, applied in transmission, clutch, one-way clutch, etc., can solve the problems of self-locking failure, accident, insufficient self-locking force, etc., and achieves small volume occupation and small installation space requirements , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

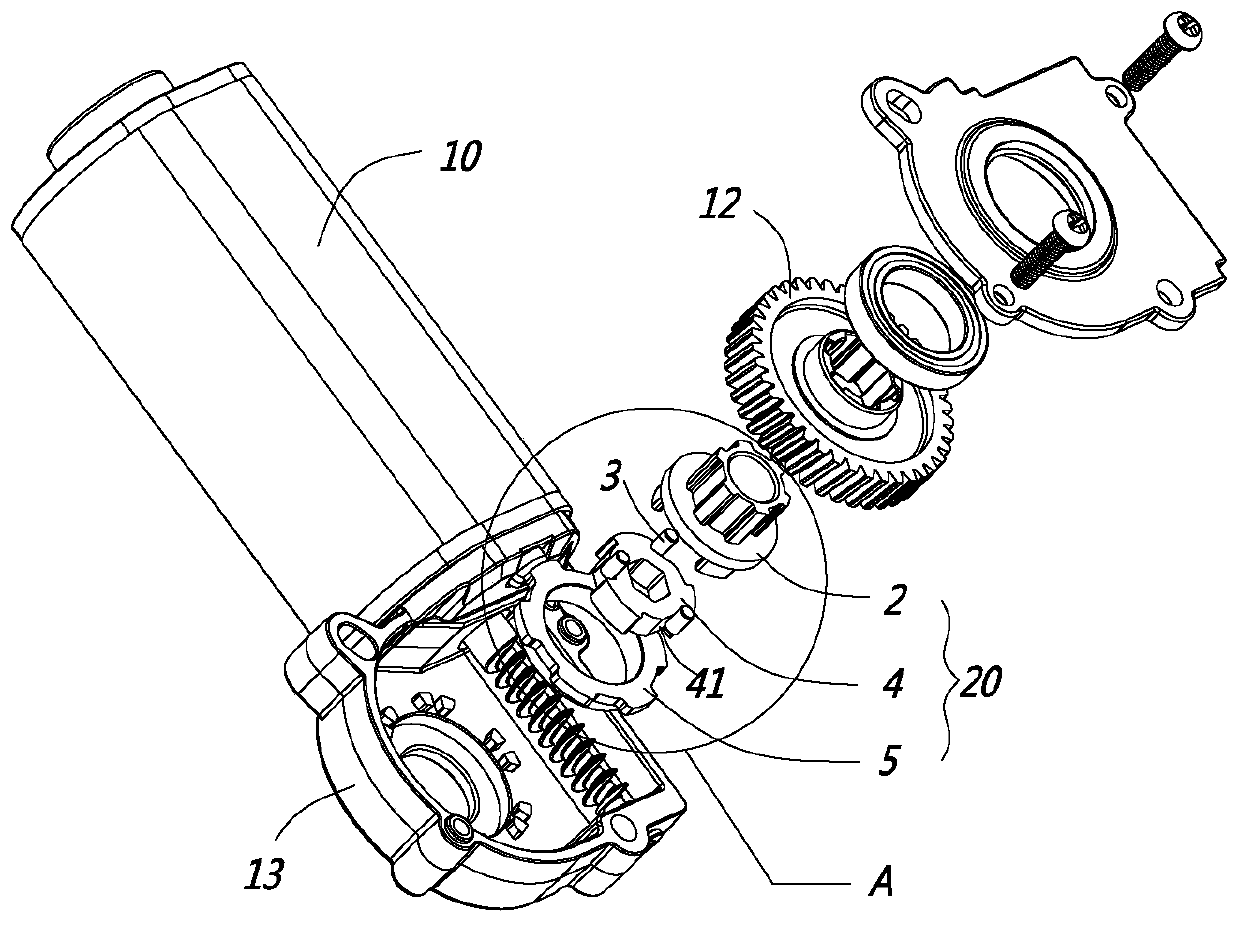

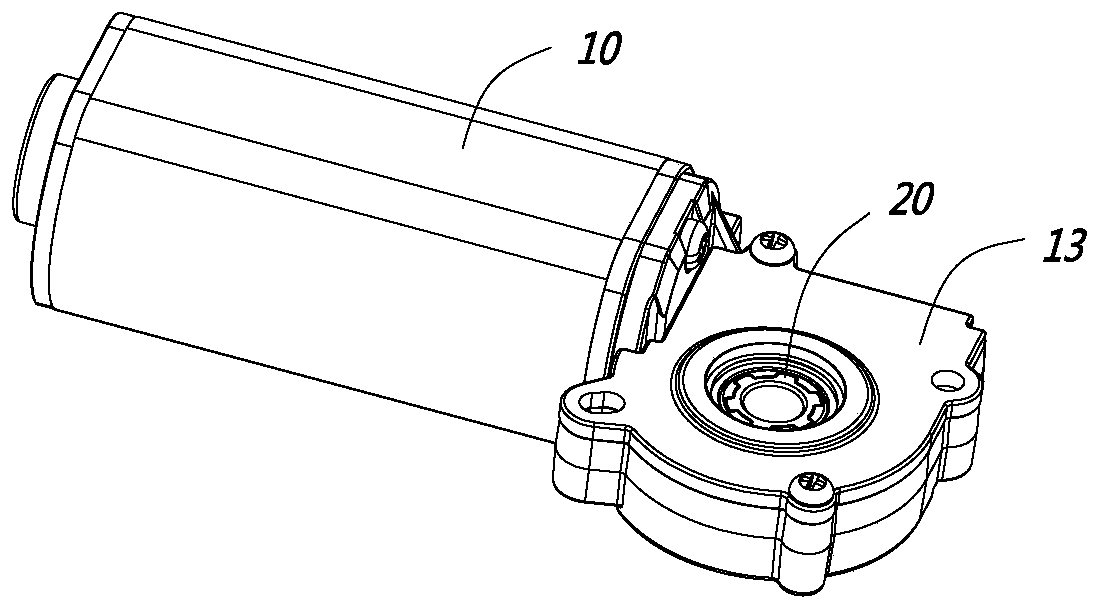

[0033] Such as Figure 1 to Figure 7 As shown, the specific preferred structure of Embodiment 1 of the self-locking device 20 of the present invention is shown.

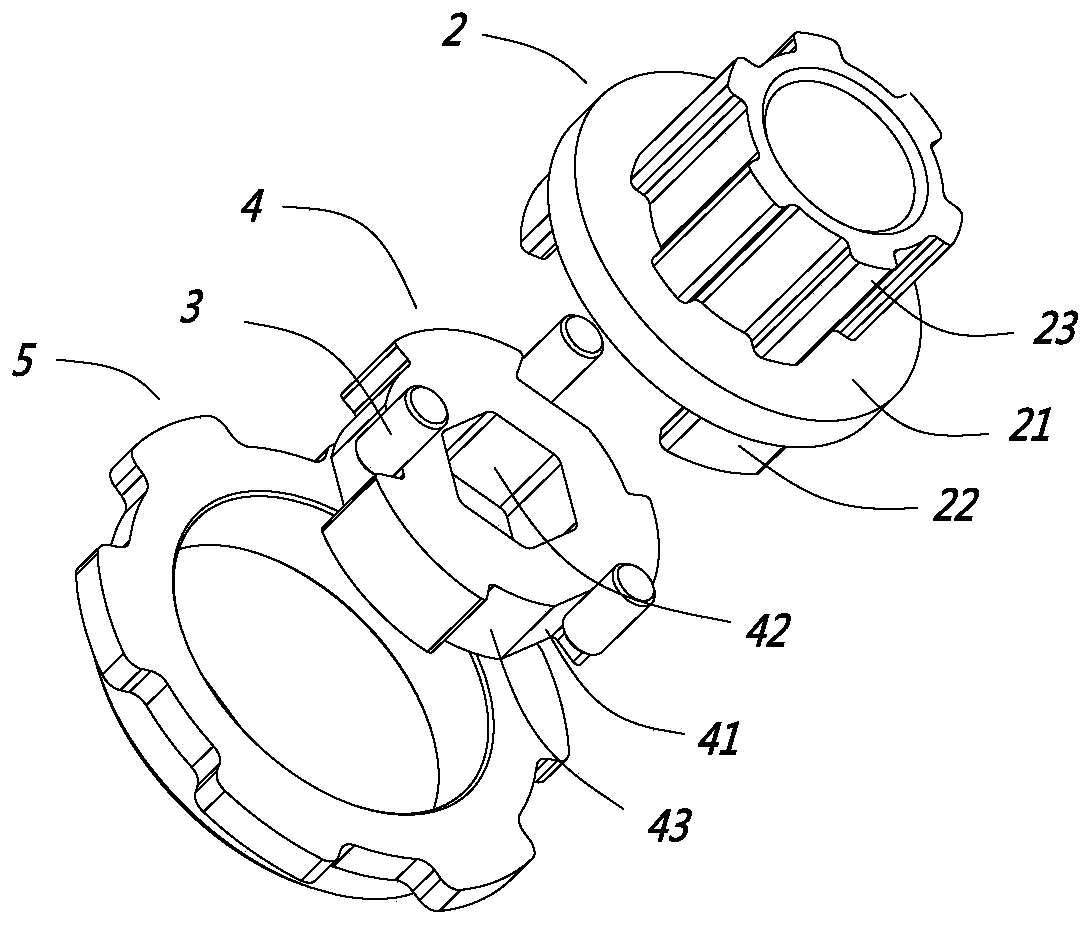

[0034] Such as figure 1 As shown, the self-locking device 20 of this embodiment is arranged between the driving motor 10 and the transmission screw of the linear actuator. The self-locking device 20 is connected with the driving motor 10 on the one hand, and is connected with the transmission screw on the other hand. In terms of, the self-locking device 20 of the present embodiment includes a track outer ring 5 and a rotating inner ring 4 rotatably arranged in the track outer ring 5, the outer side wall of the rotating inner ring 4 is provided with a ratchet groove 41, and the ratchet groove 41 is equipped with a ball 3, and a ball 3 is set in the ratchet groove 41. When the rotating inner ring 4 rotates in the forward direction, the rotating inner ring 4 can push and roll normally, and when the rotating inner ring ...

Embodiment 2

[0049] Such as Figure 8 As shown, this embodiment is a linear actuator. The linear actuator in this embodiment is a lifting column, which is mainly used on a lifting table, and mainly includes a driving motor 10, a driving screw, and a driving nut. The lifting column is a three-section column. The transmission screw includes a primary screw 61 and a secondary screw 62. The transmission nut also includes a primary nut 71 and a secondary nut 72. The specific structure and principle of this three-section lifting column are available in the existing There are a lot of disclosures in the technology, and this article will not elaborate too much. The improvement point of this embodiment is that the driving motor 10 of the lifting column is installed with a self-locking device 20 as in Embodiment 1 or the solution equivalent to it.

[0050] It should be noted that this embodiment only shows one of the lifting columns, and the linear actuator of the present invention is not limited to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com