Variable-gauge steel wheel driving device

A driving device and variable rail technology, applied in the field of rail vehicles, can solve the problems of reducing operation efficiency, complicated operation process, increasing equipment cost, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core of the present invention is to provide a variable gauge steel wheel driving device, which can change the spacing of the driving wheels and match the tracks of different gauges.

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the variable gauge steel wheel driving device of the present application will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

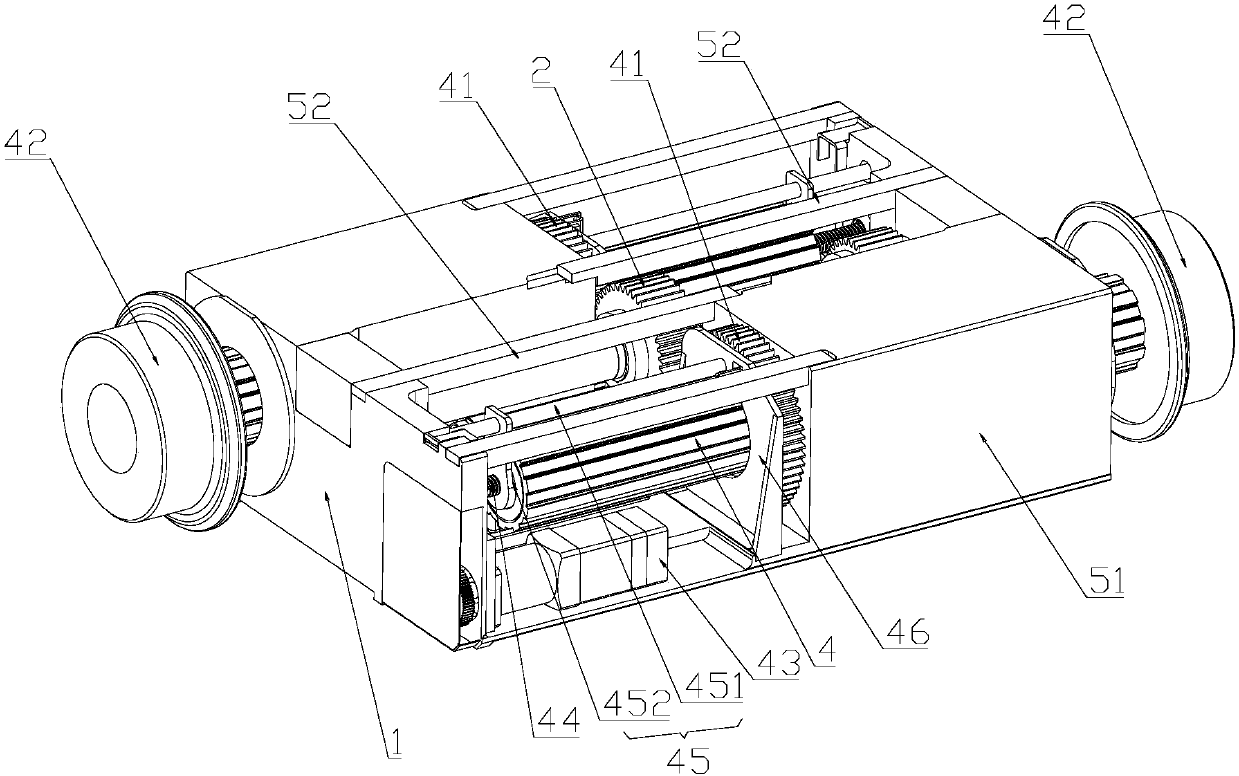

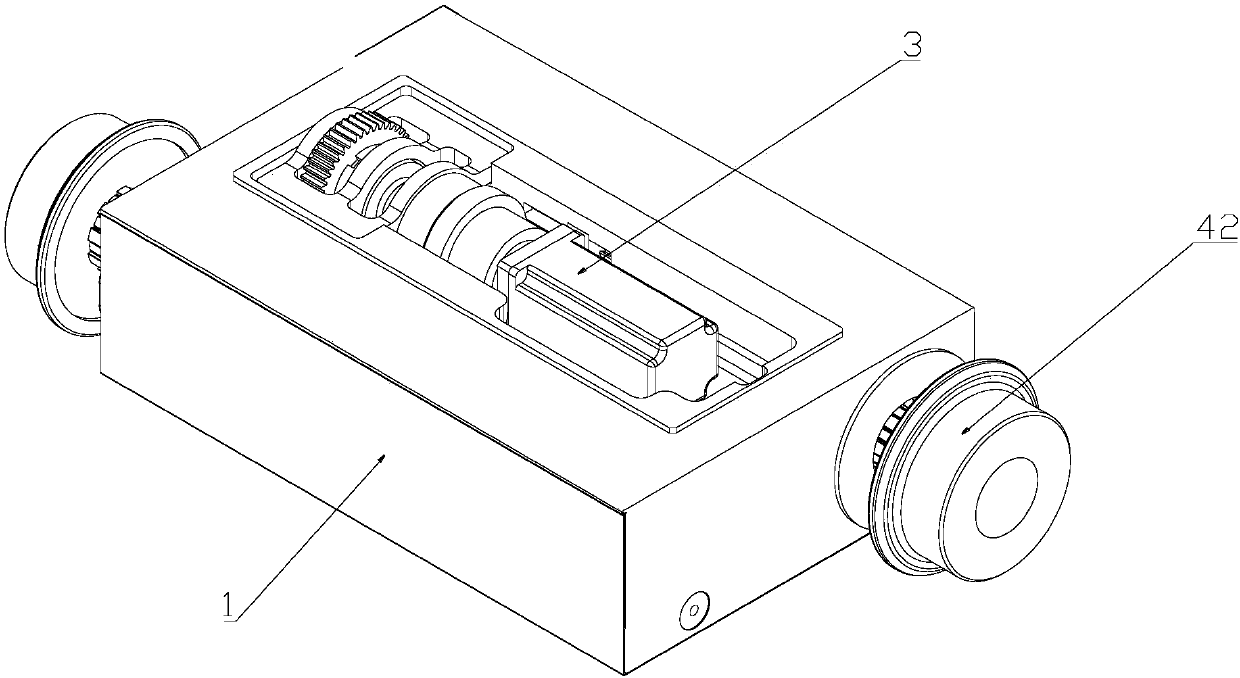

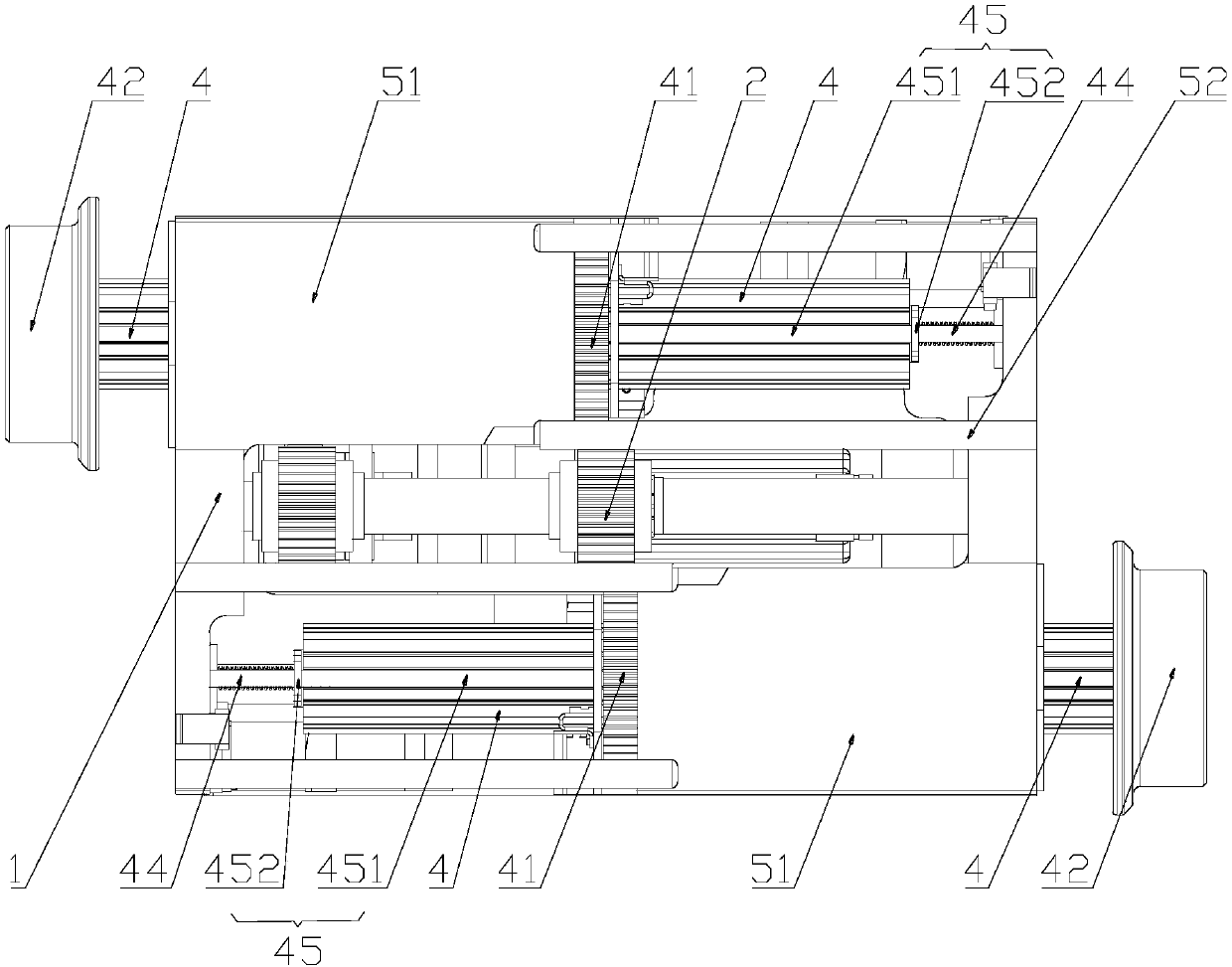

[0031] Such as Figure 1A and Figure 1B As shown, are the axonometric structural diagrams of two different angles of the variable gauge steel wheel driving device provided by the present invention respectively, Figure 1A For the oblique upward perspective, Figure 1B It is a view from the bottom; the variable gauge steel wheel driving device provided by the present invention includes structures such as a frame 1, a driving wheel 2, and a telescopic shaft 4. The frame 1 is a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com