Pressure self-balance ultrahigh pressure seal water swivel

A self-balancing, ultra-high pressure technology, applied in high-pressure water cutting in boreholes, gas control in coal mines, and punching fields, can solve problems such as low efficiency, difficulty in meeting production needs, and poor coal seam permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

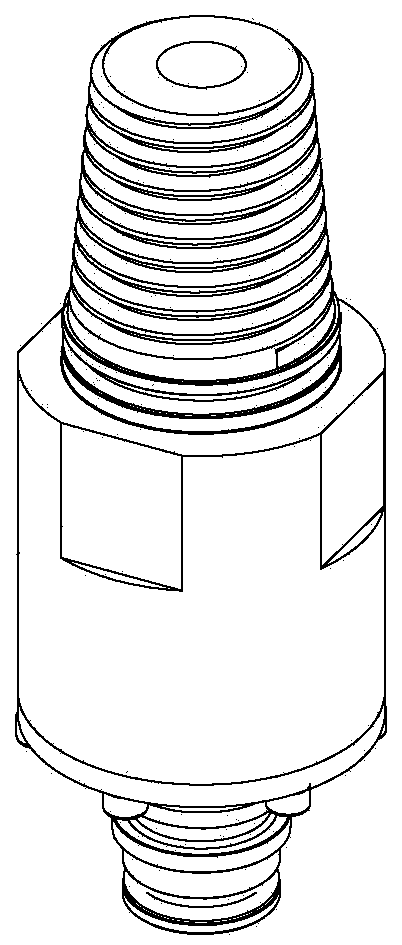

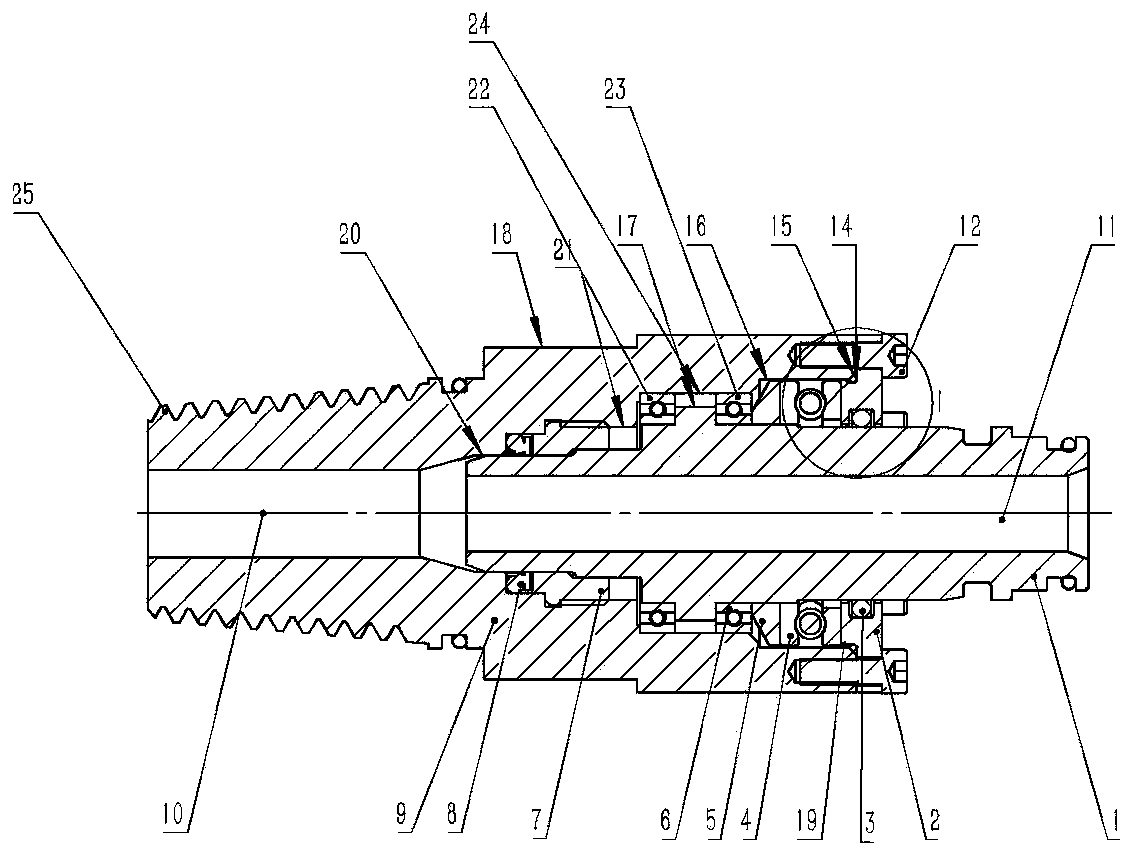

[0023] Such as Figure 1 to Figure 3 As shown, a pressure self-balancing ultra-high pressure sealing braid, including braid housing (9), pressing wire (7), mandrel (1), transition platen (5) and gland (2) from left to There is a concentric connection. In this example, the right side of the mandrel is connected to the high-pressure rubber hose, and the connection method is a quick-plug joint commonly used in coal mines. In the example, the left side is connected to the drill pipe, and the connecting thread is the thread that matches the end of the drill pipe. The water braid housing (9) and the gland (2) can rotate synchronously under the drive of the drill pipe, while the mandrel is relatively static together with the high-pressure rubber hose.

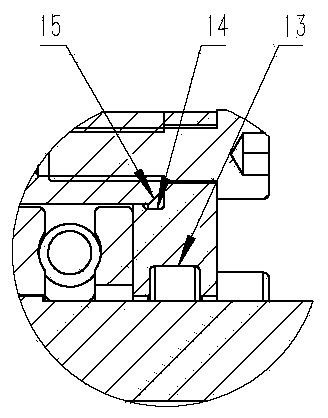

[0024] The gland (2) is fixed to the water braid housing (9) by bolts, the first sealing groove (13) and the second sealing groove (14) are arranged on the gland (2), and the sealing elements (3) and (19) are respectively placed ) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com