Steel structure beam column connection node and construction method thereof

A beam-column connection and steel structure technology, applied in the direction of building structure, building type, building, etc., can solve the problem of not fast connection of steel beams and steel columns, achieve good energy-saving effect, simple assembly, and avoid brittle fracture effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

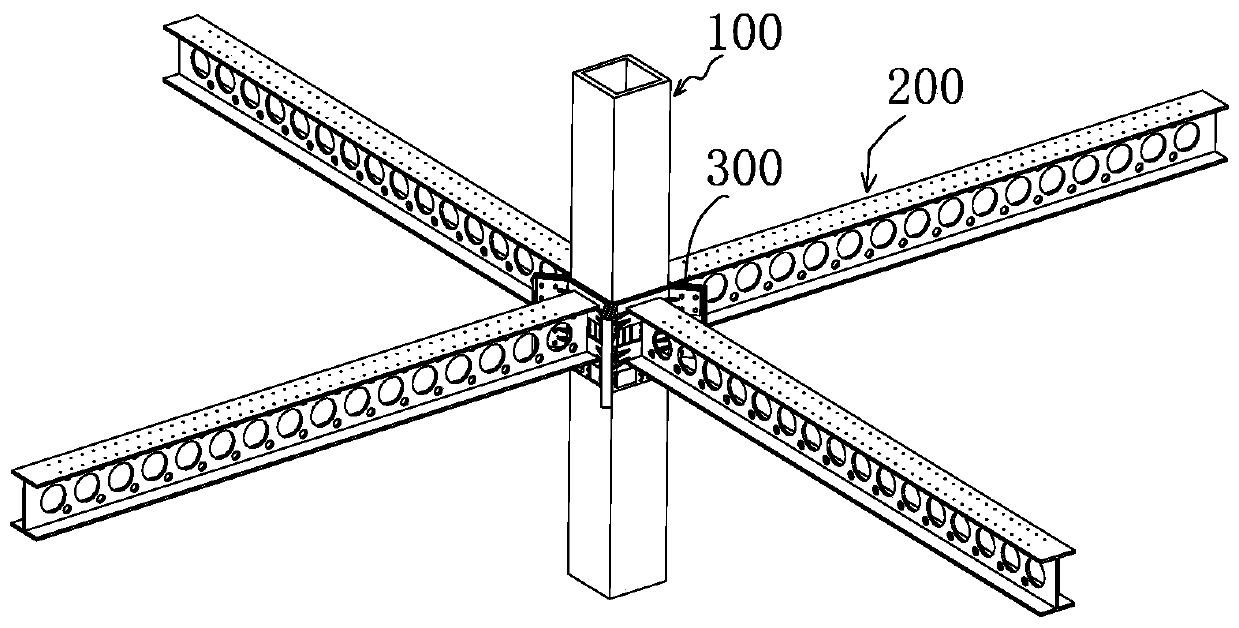

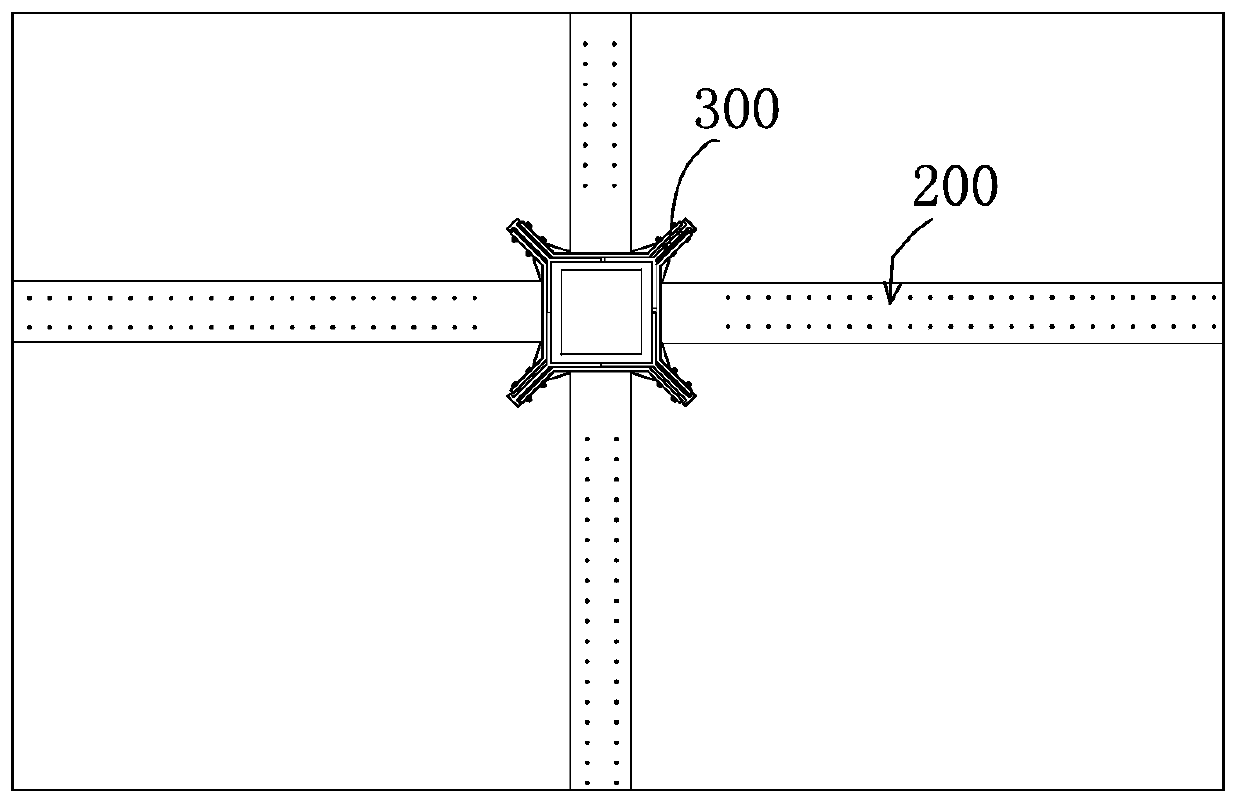

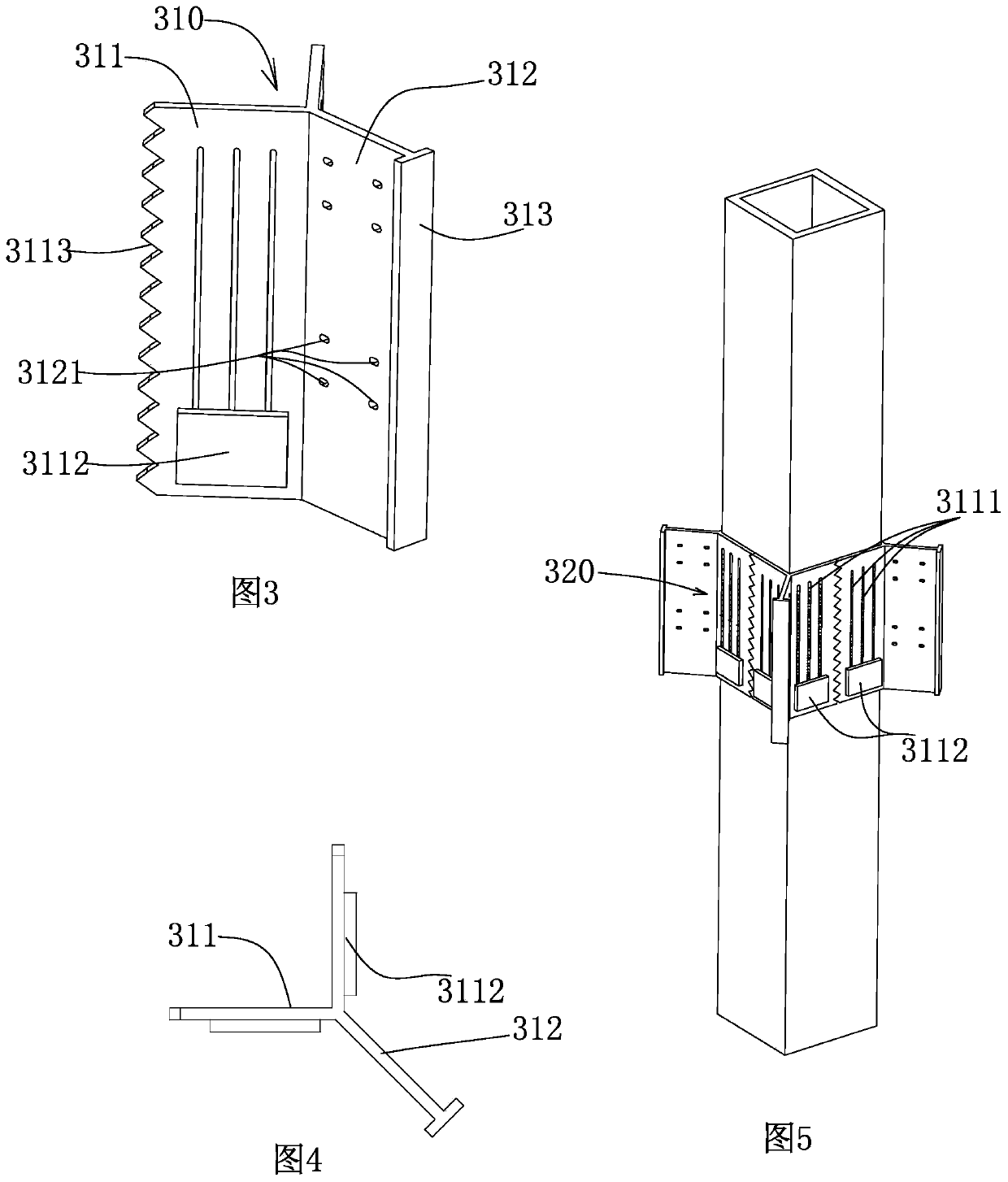

[0047] Combined with the manual figure 1 to attach Figure 8 , to describe the structure, construction and implementation process of this embodiment in detail. The steel column 100 is preferably a steel column with a rectangular or square section in this embodiment, Figure 5 The one in the figure is a square steel pipe column, which is used as a steel column.

[0048] The steel beam 200 is an I-shaped structure composed of a web and a flange. The two ends of the steel beam 200 are symmetrically provided with connecting parts 210 for connecting with two different steel columns. The connecting part of this embodiment passes through Formed by special design, having a specific structure and construction.

[0049] Correspondingly, a steel beam fixed support is provided on the steel column, and the support also has a specific structure and structure, and the connection between the support and the steel beam is connected by plugging and bolting. The connection structure has a p...

Embodiment 2

[0077] refer to Figure 9 In this embodiment, a connecting plate 214 is welded between the plug-in plates at the end of the steel beam to connect the two plug-in plates into one body to improve the local rigidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com