System and method for capturing and utilizing CO2 in low energy consumption by coupling new energy

A low-energy, new energy technology, applied in the field of energy technology and environmental protection, can solve the problems of increasing capital investment and operating costs, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

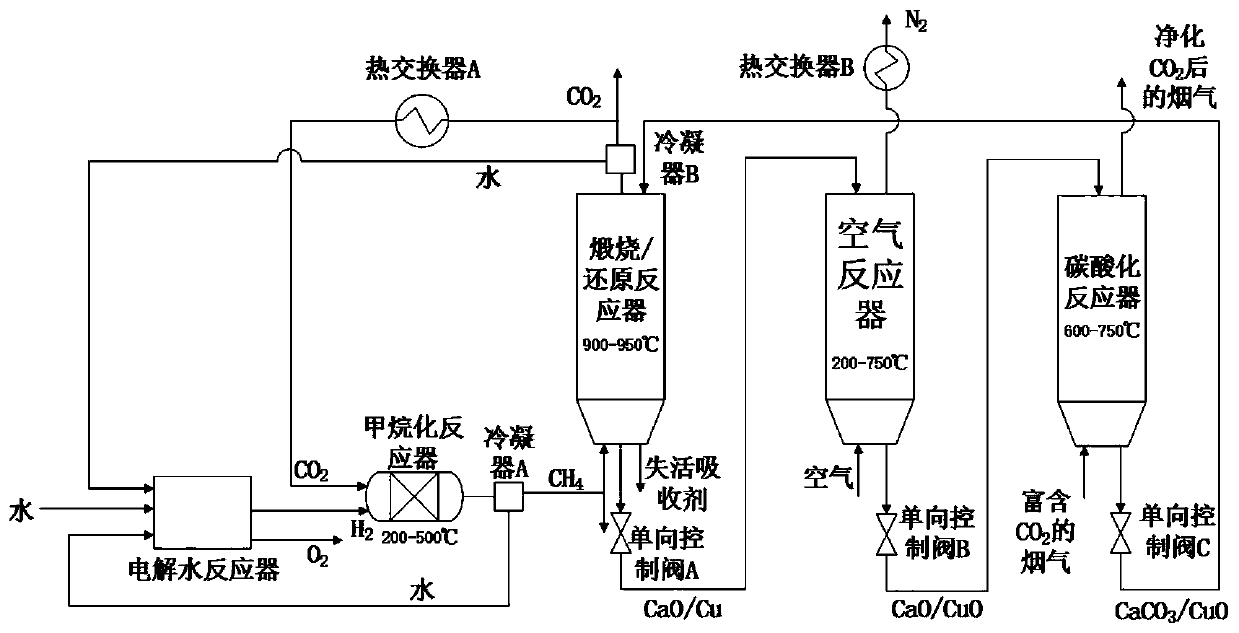

[0038] like figure 1 As shown, a coupling new energy low energy consumption to achieve CO 2 Capture and utilization system, including electrolysis water reactor 1, methanation reactor 2, calcination / reduction reactor 4, air reactor 8, carbonation reactor 11; calcination / reduction reactor 4, air reactor 8 and carbonic acid The chemical reactor 11 is connected circularly, the electrolytic water reactor 1 is connected with the methanation reactor 2 in turn, and then the methanation reactor 2 is connected with the calcination / reduction reactor 4 after going through the condenser A3.

[0039] Calcination\reduction reactor 4 is connected to heat exchanger A6 through condenser B5, heat exchanger A6 is connected to methanation reactor 2, and condenser B5 is also connected to electrolysis water reactor 1; air reactor 8 is connected at one end There is heat exchanger B10.

[0040] Calcination / reduction reactor 4 and air reactor 8, air reactor 8 and carbonation reactor 11, carbonation ...

Embodiment 2

[0042] A coupling of new energy and low energy consumption to achieve CO 2 The method of capturing and utilizing includes the following steps:

[0043] (1) The oxidized oxygen carrier and calcium-based absorbent enter the calcination / reduction reactor 4 together, and the oxidized oxygen carrier and CH 4 Reduction takes place in calcination / reduction reactor 4 to generate CO 2 and H 2 O, and release heat to calcine the calcium-based absorbent to generate CaO and CO 2 . The oxygen carrier is nickel-based oxygen carrier, and the calcium-based absorbent is CaO / Ca(OH) 2 / CaCO 3 , the calcining temperature of the calcium-based absorbent is 950°C, and the reaction pressure is normal pressure.

[0044] (2) Generated CO 2 and H 2 O separates CO through condenser B5 2 and H 2 O, where H 2 O is sent to electrolysis water reactor 1 as raw material, while CO 2 After the heat is recovered by the heat exchanger A6, the H 2 Mixed in Methanation Reactor 2, CO 2 Methanation reacti...

Embodiment 3

[0049] like figure 1 and 2 As shown, a coupling new energy low energy consumption to achieve CO 2 The method of capturing and utilizing includes the following steps:

[0050] (1) The oxidized oxygen carrier and calcium-based absorbent enter the calcination / reduction reactor 4 together, and the oxidized oxygen carrier and CH 4 Reduction takes place in calcination / reduction reactor 4 to generate CO 2 and H 2 O, and release heat to calcine the calcium-based absorbent to generate CaO and CO 2 . The oxygen carrier is copper-based oxygen carrier, and the calcium-based absorbent is CaCO 3 , the temperature for calcining the calcium-based absorbent is 940°C, and the reaction pressure is normal pressure.

[0051] (2) Generated CO 2 and H 2 O separates CO through condenser B5 2 and H 2 O, where H 2 O is sent to electrolysis water reactor 1 as raw material, while CO 2 After the heat is recovered by the heat exchanger A6, the H 2 Mixed in Methanation Reactor 2, CO 2 Methana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com