A kind of preparation method of high solid content monodisperse pure acrylic colloidal emulsion

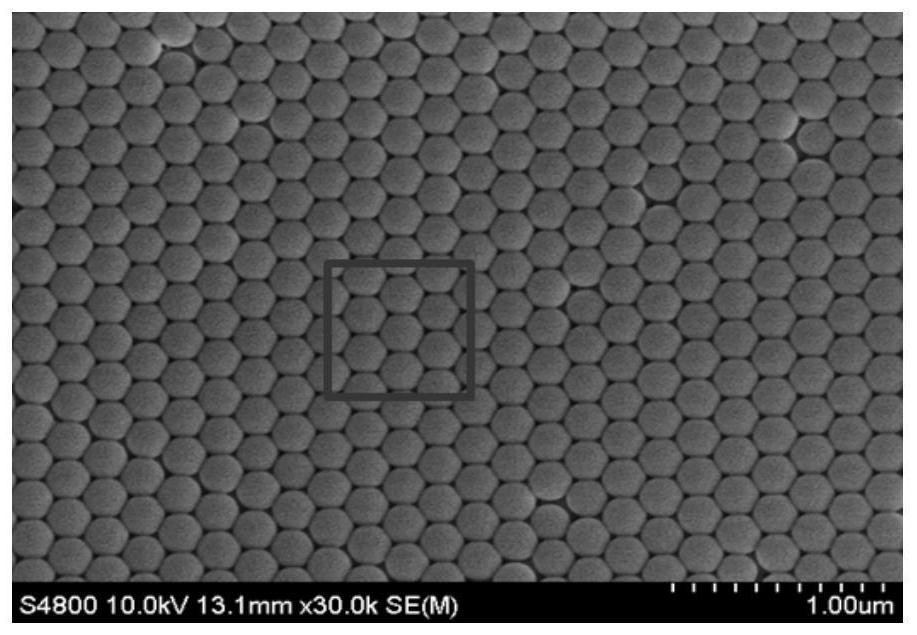

A high-solid content, colloidal emulsion technology, applied in instruments, optical components, optics, etc., can solve the problems of low utilization rate of equipment, high production and storage costs, etc., and achieve the effect of easy heat dissipation, uniform shape, and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

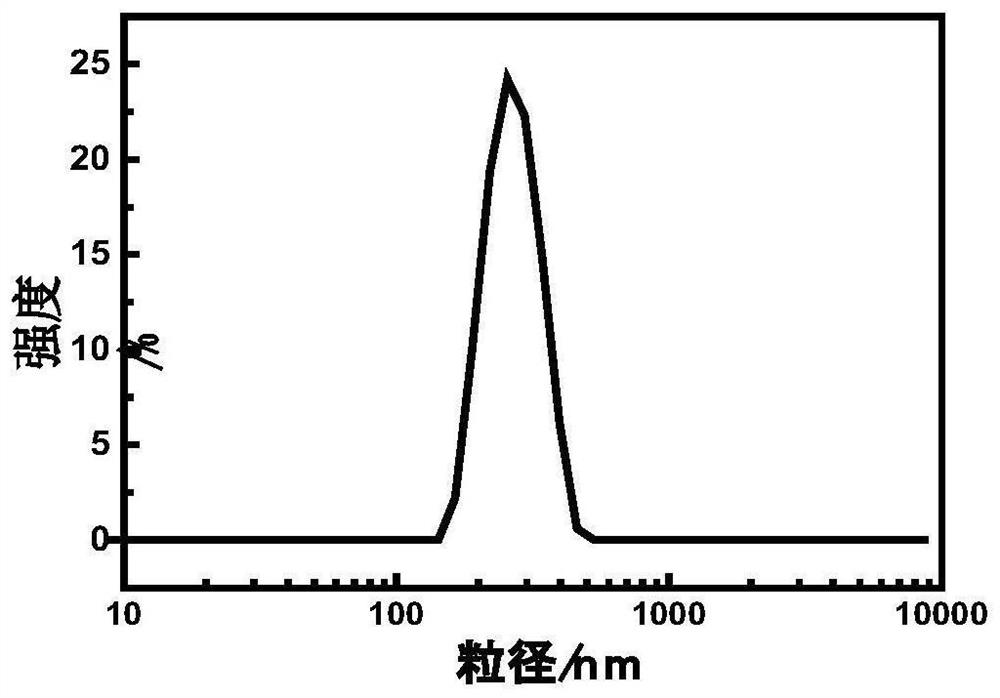

[0036] Weigh 10g of deionized water, 60g of methyl methacrylate, 4g of α-methacrylic acid, 7g of butyl acrylate, 0.5g of amphoteric emulsifier CO897, 0.2g of cationic emulsifier sodium lauryl sulfate, and 0.02g of protective colloid with a balance Stir and mix polyvinylpyrrolidone in a 200mL beaker as a pre-emulsion; use a balance to weigh 8g of deionized water, 16g of methyl methacrylate, 4g of α-methacrylic acid, 6g of butyl acrylate, and 0.4g of amphoteric emulsifier CO897 , 0.2g cationic emulsifier sodium lauryl sulfate, 0.02g protective colloid polyvinylpyrrolidone are stirred and mixed in a 100mL beaker as a seed solution for later use; take 0.48g initiator potassium persulfate with a balance and add 20g deionized water to prepare Initiator solution: 120g deionized water, 0.3g amphoteric emulsifier CO897, 0.05g cationic emulsifier sodium lauryl sulfate, 0.02g protective colloid polyvinylpyrrolidone, 0.04g initiator potassium persulfate were stirred and mixed with a balanc...

Embodiment 2

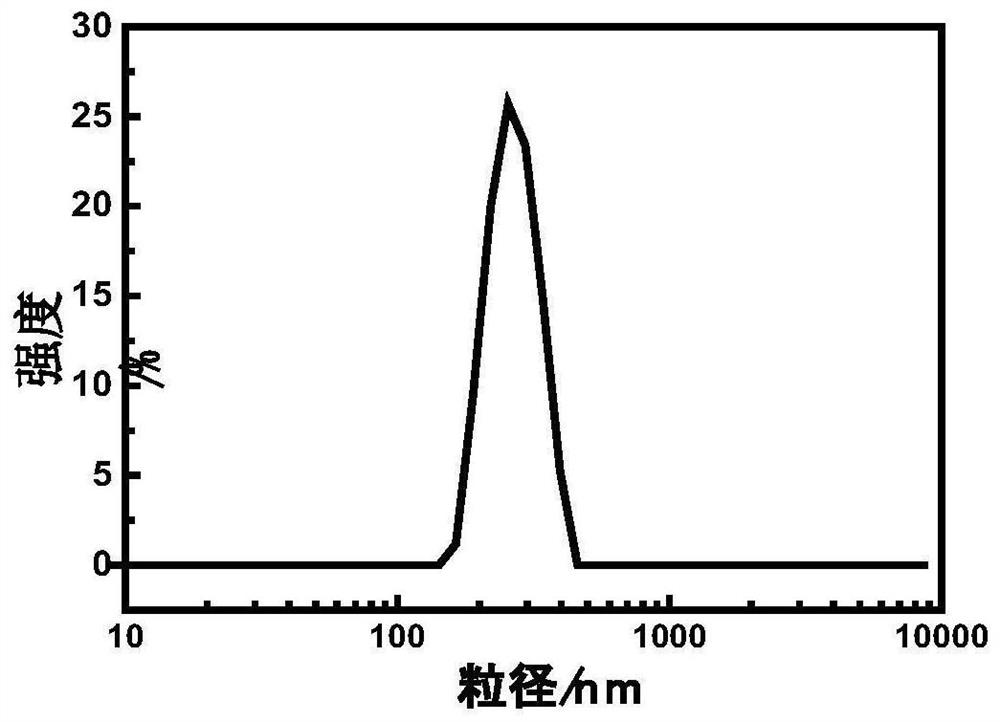

[0038]Weigh 10g of deionized water, 65g of methyl methacrylate, 4g of α-methacrylic acid, 8g of butyl acrylate, 0.55g of amphoteric emulsifier CO897, 0.2g of cationic emulsifier sodium lauryl sulfate, and 0.02g of protective colloid with a balance Stir and mix polyvinyl alcohol in a 200mL beaker as a pre-emulsion for later use; use a balance to weigh 8g of deionized water, 20g of methyl methacrylate, 4g of α-methacrylic acid, 8g of butyl acrylate, 0.5g of amphoteric emulsifier CO897, 0.2g cationic emulsifier sodium lauryl sulfate, 0.02g protective colloid polyvinyl alcohol are stirred and mixed in a 100mL beaker as a seed solution for later use; weigh 0.5g initiator ammonium persulfate with a balance and add 15g of deionized water to prepare initiation 120g deionized water, 0.32g amphoteric emulsifier CO897, 0.06g cationic emulsifier sodium lauryl sulfate, 0.02g protective colloid polyvinyl alcohol, 0.05g initiator ammonium persulfate were stirred and mixed uniformly with a bal...

Embodiment 3

[0040] Weigh 8g of deionized water, 70g of methyl methacrylate, 6g of α-methacrylic acid, 8g of butyl acrylate, 0.5g of amphoteric emulsifier CO897, 0.15g of cationic emulsifier sodium lauryl sulfate, and 0.02g of protective colloid with a balance Stir and mix polyethylene glycol in a 500mL beaker as a pre-emulsion; use a balance to weigh 6g of deionized water, 20g of methyl methacrylate, 4g of α-methacrylic acid, 7g of butyl acrylate, and 0.45g of amphoteric emulsifier CO897 , 0.15g cationic emulsifier sodium lauryl sulfate, 0.02g protective colloid polyethylene glycol are stirred and mixed in a 200mL beaker as a seed solution for later use; take 0.55g initiator potassium persulfate with a balance and add 15g deionized water to prepare Initiator solution; weigh 120g deionized water, 0.28g amphoteric emulsifier CO897, 0.04g cationic emulsifier sodium lauryl sulfate, 0.03g protective colloid polyethylene glycol, 0.04g initiator potassium persulfate and mix evenly After that, tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com