Tamping machine

A tamping machine and the same technology, applied in the direction of roads, road repair, roads, etc., can solve the problems of low soil moisture content, easy to raise large dust, low tamping operation efficiency, etc., to achieve convenient operation, accurate positioning, The effect of increasing soil moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

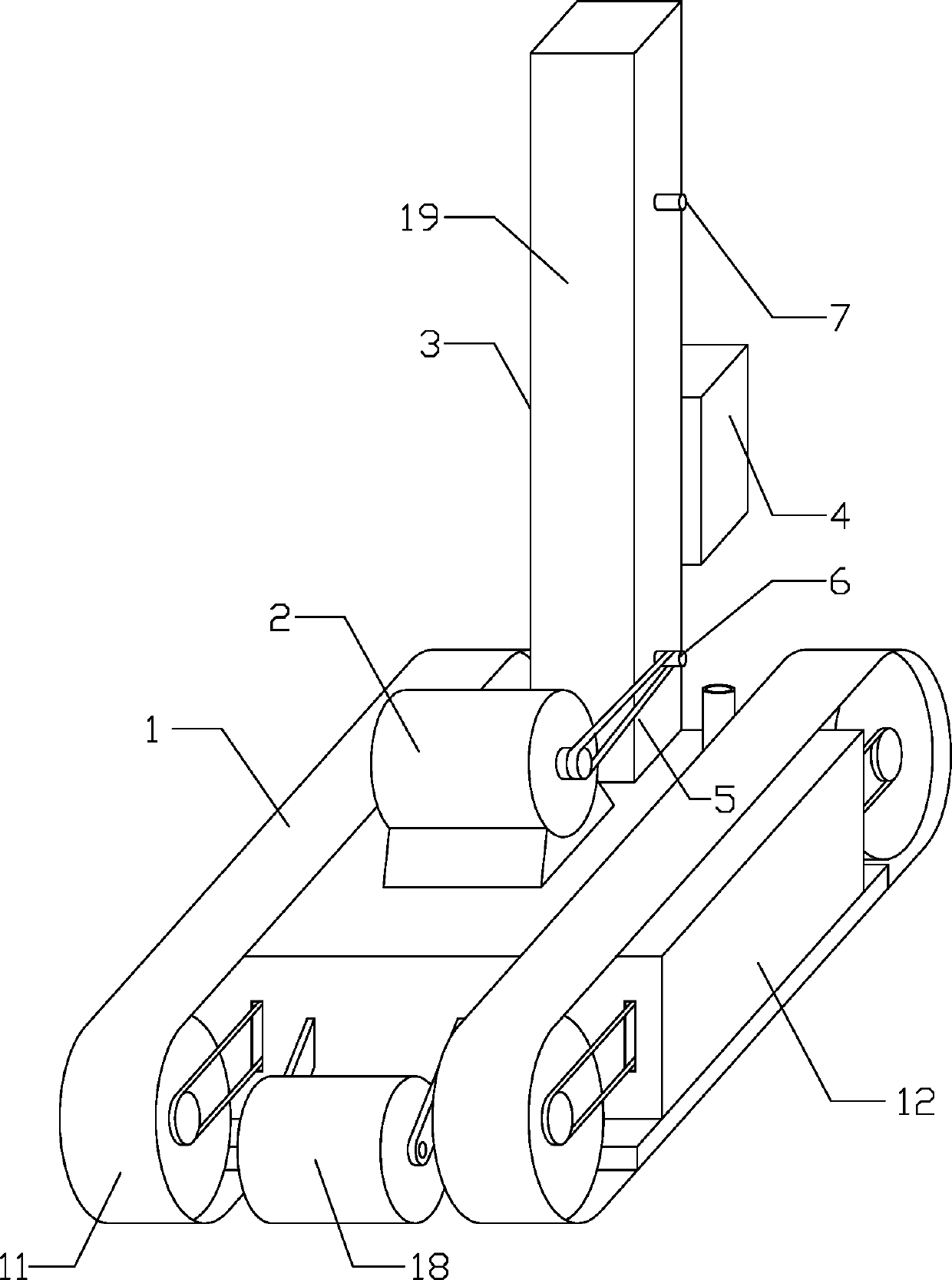

[0028] Such as Figure 1-6 Among them, a tamping machine includes a traveling mechanism 1 and a tamping mechanism 3, said traveling mechanism 1 is provided with a drive motor 2 and a tamping mechanism 3, and the drive motor 2 is connected to the tamping mechanism 3;

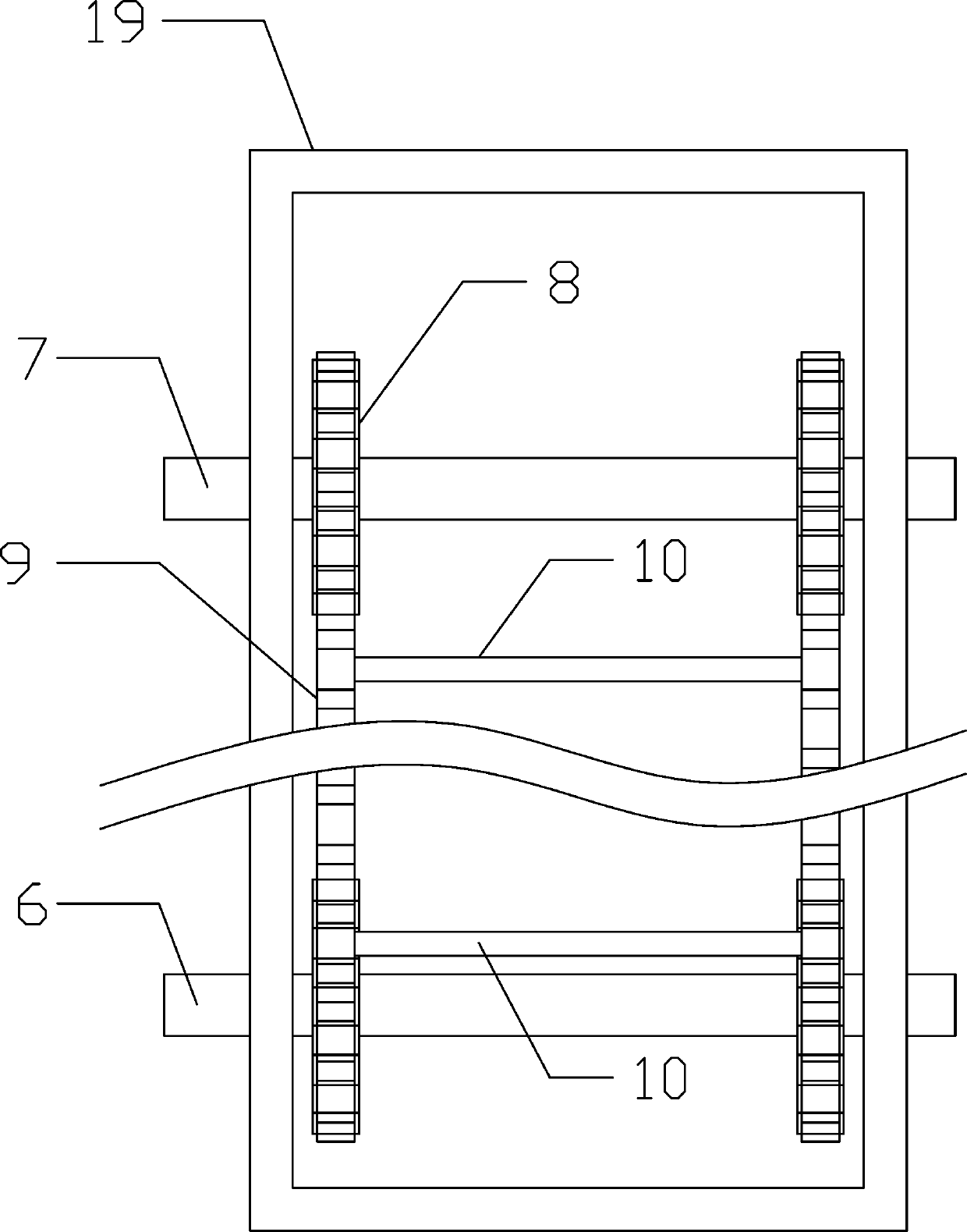

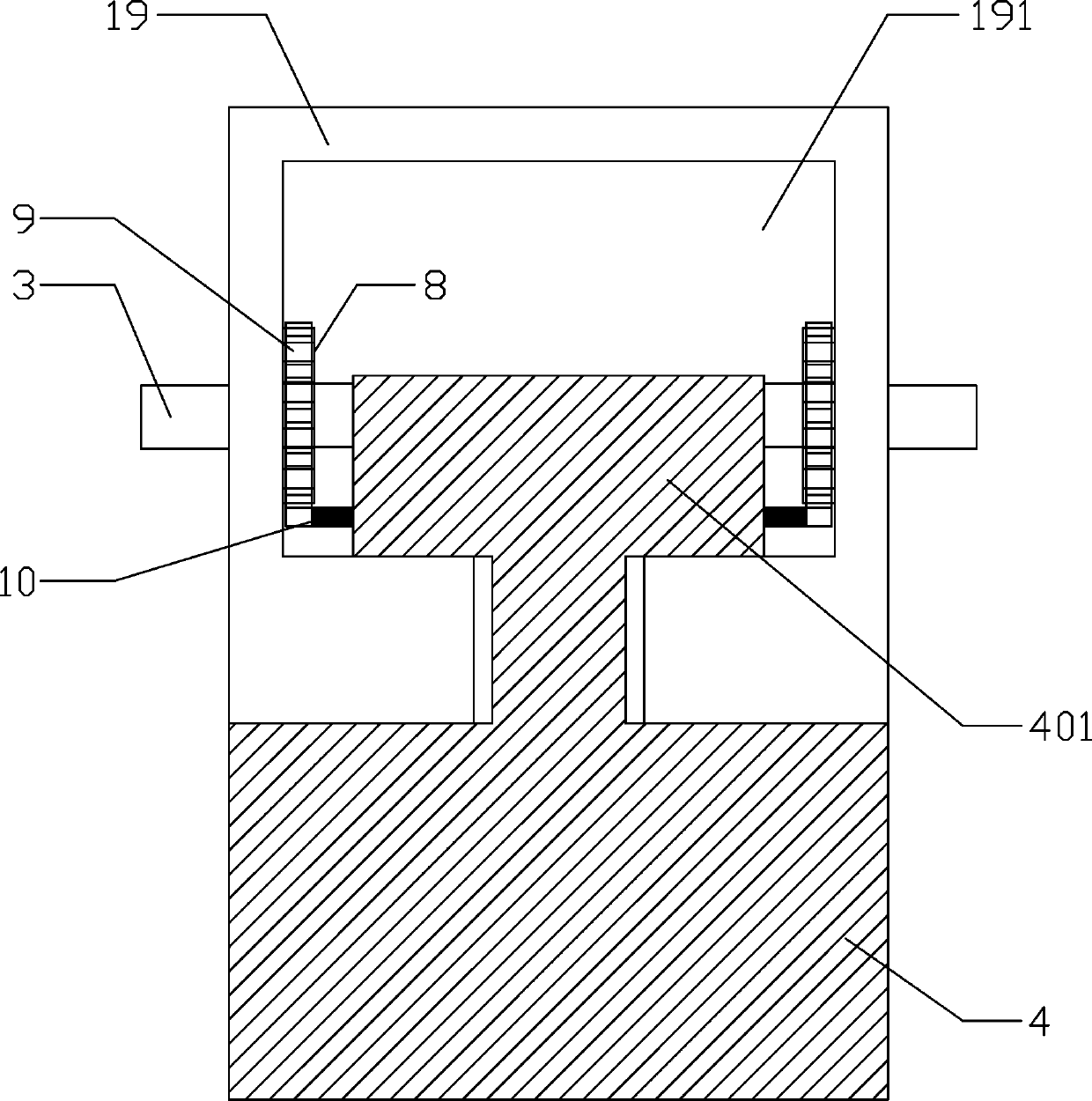

[0029] The tamping mechanism 3 includes a vertically arranged guide rod 19 and a weight 4 arranged on one side of the guide rod 19, the described guide rod 19 is provided with a vertical chute 191, and the described weight 4 A slider 401 is provided on it, and the slider 401 is arranged in the chute 191;

[0030] The upper and lower ends of the guide rod 19 are respectively provided with a first rotating shaft 6 and a second rotating shaft 7, and the first rotating shaft 6 and the second rotating shaft 7 are arranged transversely on the guide rod 19. The first rotating shaft 6 and the second rotating shaft Rotating shaft 7 is provided with gear 8 on the two ends of the part that is positioned at the chute 191 of...

Embodiment 2

[0036] Such as Figure 7 On the basis of Embodiment 1, the base 12 adopts a hollow structure, and there are two chambers in the base 12, one of which is provided with a biaxial motor 13 for driving the crawler belt 11, and the other chamber is a water tank 14 The top of the water tank 14 is provided with a water injection port 15, the water tank 14 is provided with a water pump 16, and the water pump 16 is provided with an outlet pipe 17, and one end of the water outlet pipe 17 is connected with the water pump 16, and the other end passes through the end face of the base 12 and extends to the outside of the end face.

[0037] In a preferred solution, the water tank 14 is arranged at one end close to the base 12 of the tamping mechanism 3 , and the water outlet end of the water outlet pipe 17 is arranged directly below the weight 4 .

[0038] The specific working principle of this device is as follows:

[0039] Move the device to the position where ramming is required, turn on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com