A kind of monocrystalline silicon texturing additive and its application of adding graphene oxide quantum dots

A graphene quantum dot, silicon texturing technology, applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of hindering the contact between the etchant and the silicon surface, reducing the texturing efficiency, etc., so as to improve the photoelectric conversion. efficiency, improve texturing efficiency, and eliminate the effect of uneven light and dark

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

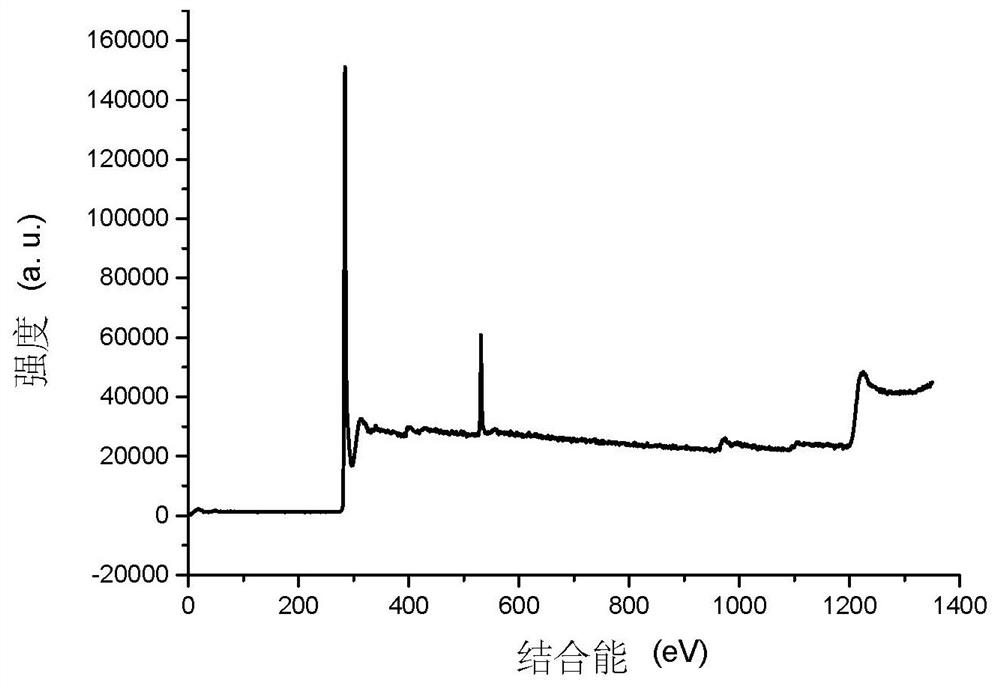

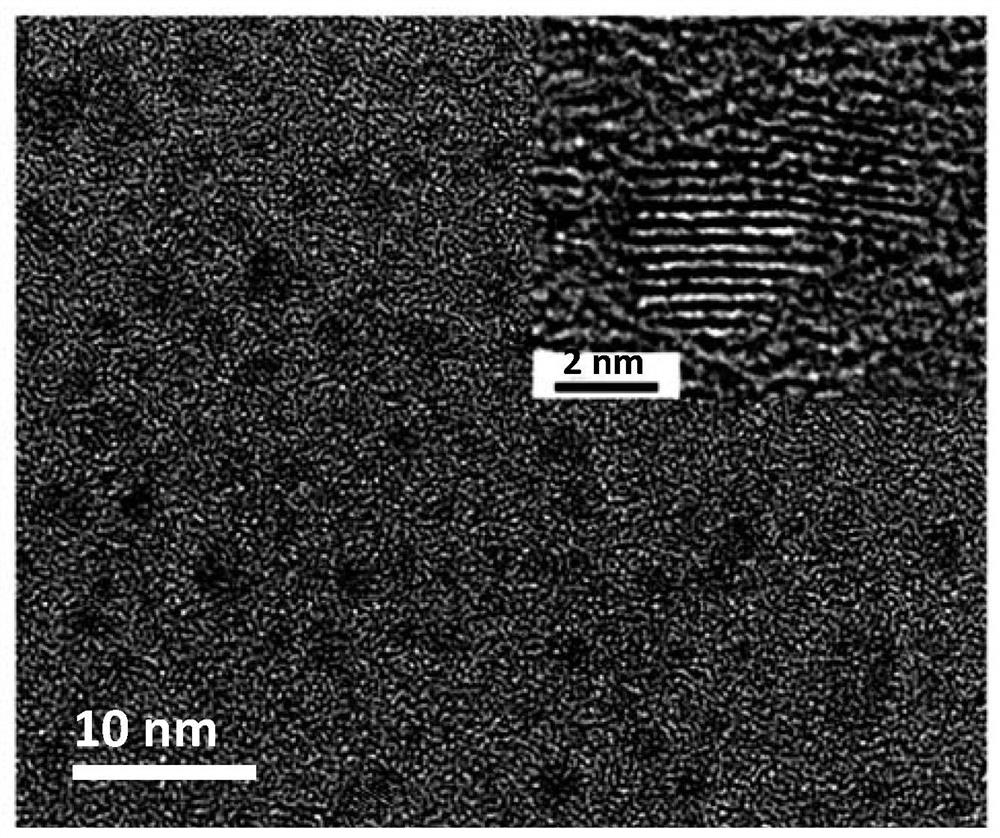

[0043] Disperse 1g of graphene oxide (2-100μm in size) in 10g of concentrated nitric acid, ultrasonically peel off the graphene oxide for 5 hours to form a brown dispersion liquid; heat the obtained brown dispersion liquid to 60°C and keep it for 5 hours; in the above solution Adding concentration is the NaOH solution adjustment pH value of 2M to neutrality; Gained liquid uses high-speed centrifuge separation process 7000rpm, 4min, obtains the upper layer brown solution containing graphene oxide quantum dot ( image 3 : graphene oxide quantum dot size is 2nm, oxygen content is 45at% (see figure 2 ); Graphene oxide quantum dot content is 0.5wt% in the solution);

[0044] The graphene oxide quantum solution, PEG400, NaOH, and water are configured according to the weight ratio of 6:4:0.8:89.2 to obtain the texturing additive;

[0045] Configure a NaOH aqueous solution with a concentration of 1.2wt%, and add the above texturing additives to the NaOH aqueous solution according to...

Embodiment 2

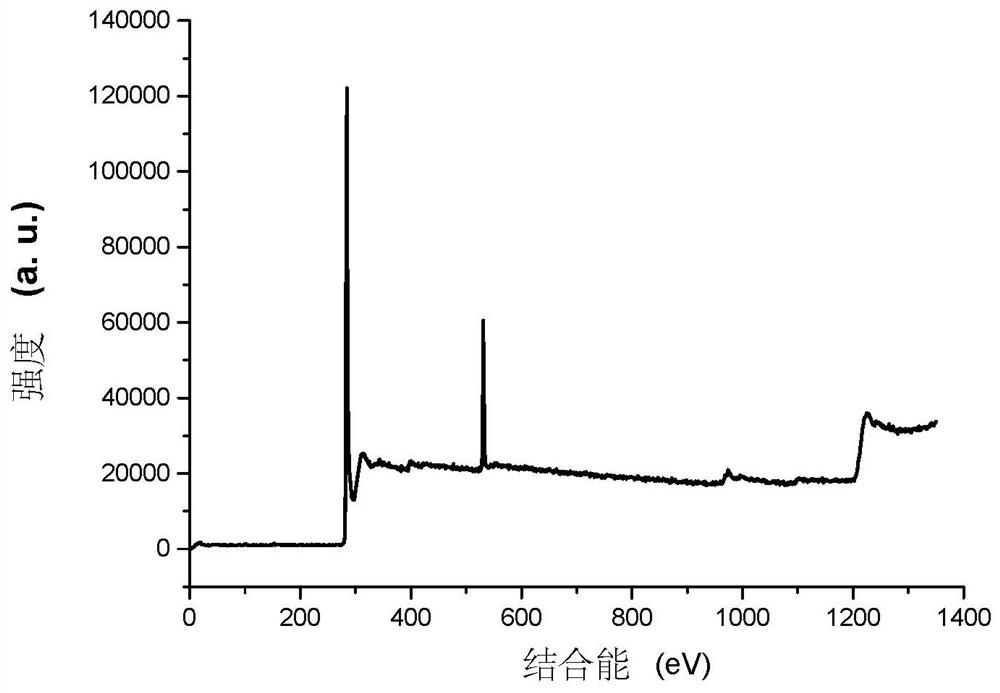

[0049] 0.5 g of graphene oxide (size 2-100 μm) was dispersed in 3 g of concentrated nitric acid, and the graphene oxide was fully peeled off by ultrasonication for 8 hours to form a brown dispersion liquid. Heat the brown dispersion liquid to 90°C and keep it for 2h; add K at a concentration of 0.5M to the above solution 2 CO 3 The pH of the solution was adjusted to neutral. Gained liquid uses high-speed centrifuge separation process 9000rpm, 2min, obtains the upper layer brown solution containing graphene oxide quantum dot (the size of graphene oxide quantum dot is 5nm, and oxygen content is at 65% (see figure 1 ); Graphene oxide quantum content is 0.3wt% in the solution);

[0050] The graphene oxide quantum solution, P123 solution, Na 2 CO 3 , and water are configured according to the weight ratio of 10:1:1:88 to obtain the texturing additive;

[0051] Then configure 2% NaOH texturing solution (NaOH aqueous solution), and add the above texturing additives into the NaOH ...

Embodiment 3

[0055] 0.3g of glucose was dissolved in 50ml of deionized water, and subjected to hydrothermal treatment at 120°C for 800min to obtain a graphene oxide quantum dot solution (see Figure 6 , the size of the graphene oxide quantum dot is 3nm, and the oxygen content is at 38% (atomic ratio); the graphene oxide quantum dot content is 1.3wt% in the solution;

[0056] The graphene oxide quantum solution, PVA, Na 2 CO 3 , NaOH and water are configured according to the weight ratio of 5:2:2:2:89 to obtain the texture additive;

[0057] Then configure 4% NaOH texturing solution, and add the above texturing additives into the NaOH texturing solution according to 3% by weight to form an alkaline texturing solution;

[0058] At 90°C, put the monocrystalline silicon wafer into the above alkaline texturing solution for etching for 450s;

[0059] After texturing, the obtained monocrystalline silicon wafers were washed with water and dried. The test results show that the size of the pyram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com