A Rubber Forming Method for Concave Curved Surface and Semi-arc-shaped Reinforced Bend Sheet Metal Parts

A technology of sheet metal parts and semi-circular arcs, applied in the field of aircraft manufacturing, can solve the problems such as the large curvature limitation of partition parts, and achieve the effects of improving the forming accuracy, and the installation and operation methods are simple, convenient and easy to achieve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

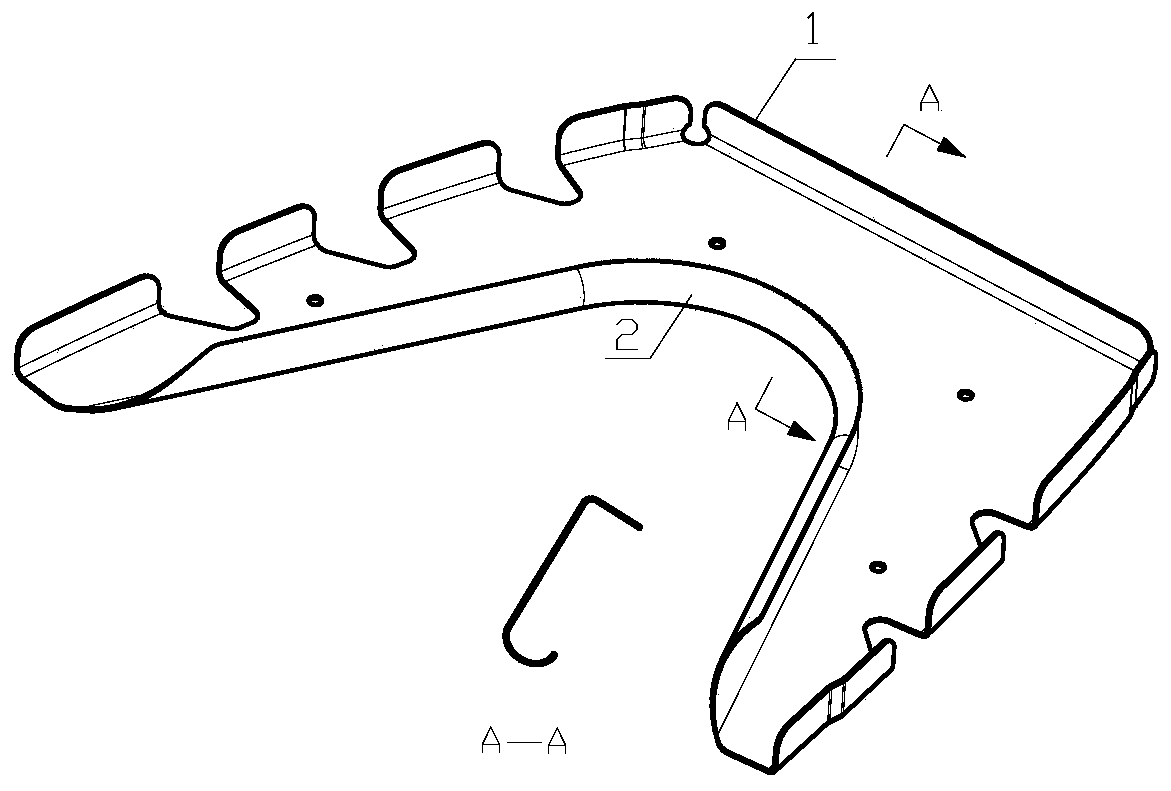

[0024] Referring to the accompanying drawings, the aircraft parts provided by the embodiment are as figure 1 As shown, the part 1 is a sheet metal part with curved edges on both the inner and outer sides. The inner side has a large curvature, concave shape, and the bent side is in the shape of a semicircle. The biggest problem in forming the part with the existing technology is that the inner concave surface 2 is semicircle. The curved edge is prone to thinning and cracking, and it completely depends on the skill level of the workers, and the surface quality of the parts is poor.

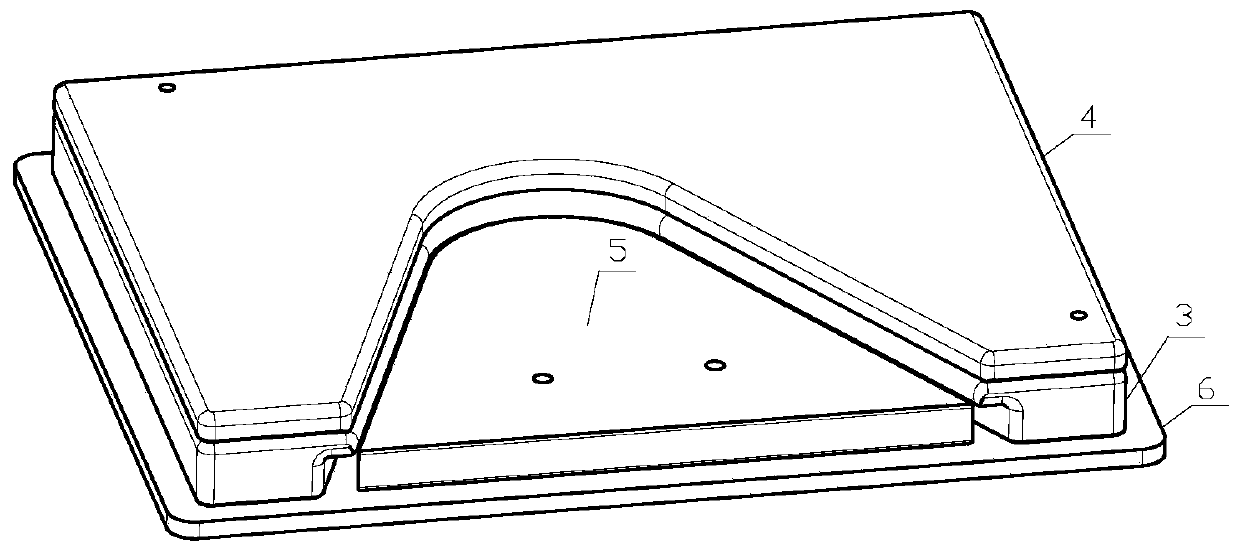

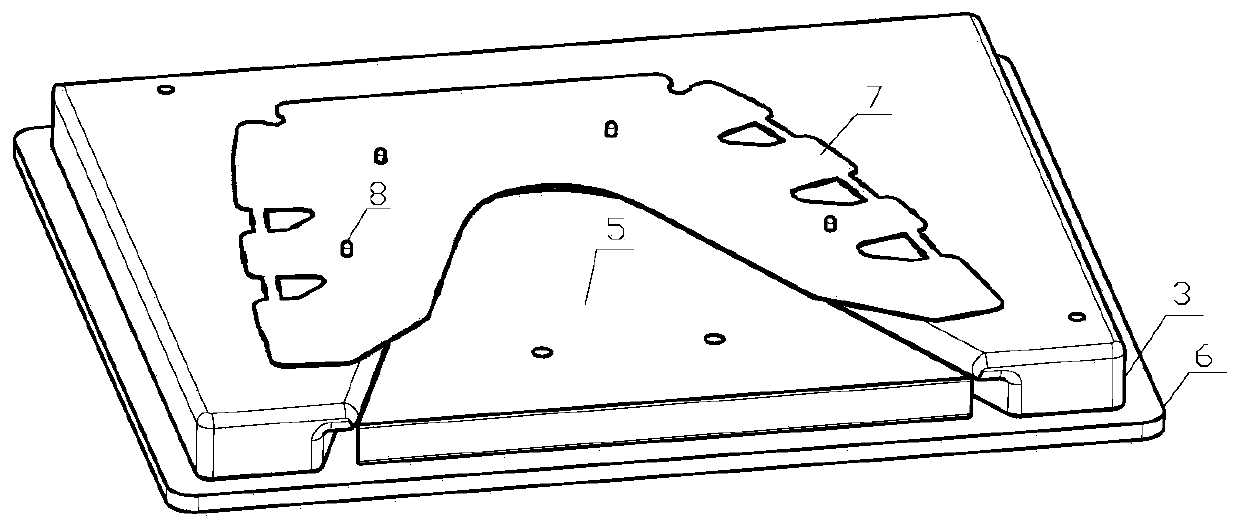

[0025] The molding die that this application proposes is as figure 2 As shown, the forming mold includes a forming die 3, a cover plate 4, an auxiliary pad 5 and a base plate 6, the base plate 6 is a cuboid frame, and the shape of the working surface of the forming die 3 is consistent with the shape of the inner concave surface 2 of the sheet metal part 1 to be formed. The cross-section of the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com