Grass drying and crushing apparatus

A technology for drying and pulverizing forages is applied in the directions of drying gas arrangement, drying, and dryers, which can solve the problems of unadjustable pulverization degree and low pulverization efficiency, and achieve good pulverization effect, high pulverization efficiency, and improved pulverization efficiency. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

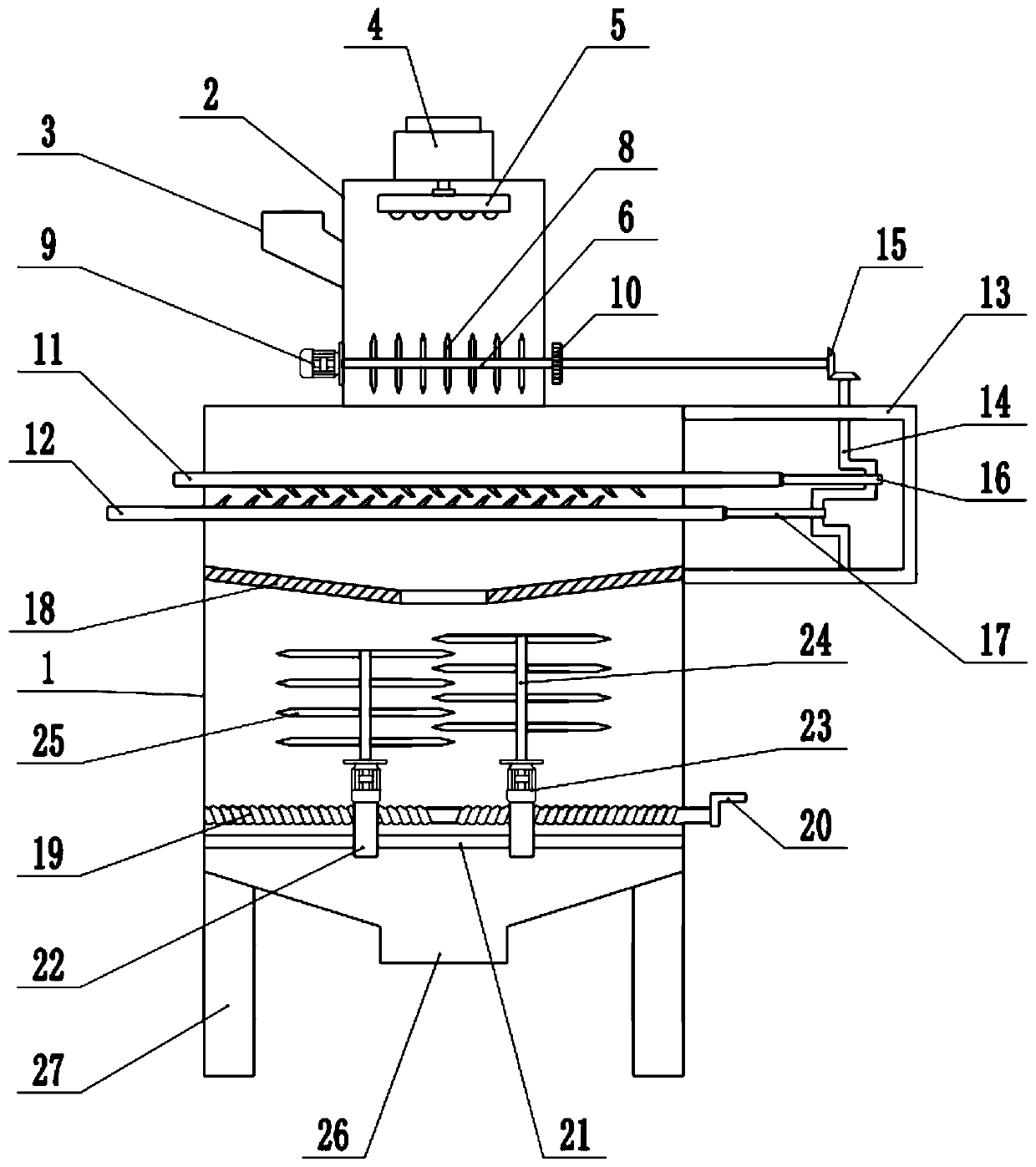

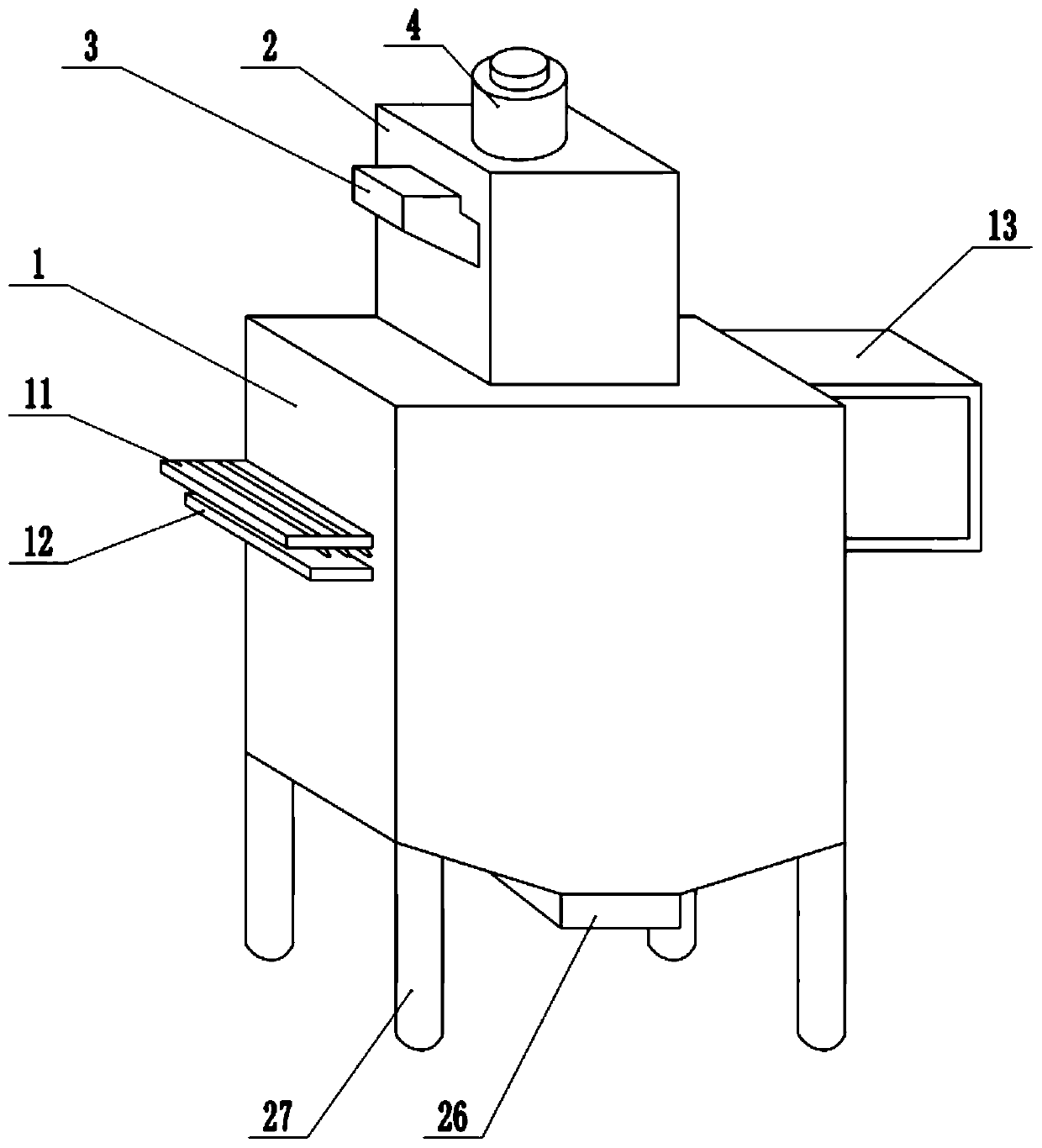

[0021] see figure 1 , 2 And 4, in the embodiment of the present invention, an integrated device for pasture drying and crushing includes a crushing chamber 1, a drying chamber 2, a crushing motor 23 and a crushing blade 25, and the upper surface of the crushing chamber 1 is fixedly connected with a drying chamber 2 , the drying bin 2 is connected with the crushing bin 1, and the side wall of the drying bin 2 is equipped with a feeding port 3, and the grass to be processed is put into the drying bin 2 through the feeding port 3, and a hot air blower 4 is installed on the upper surface of the drying bin 2 , the interior of the drying bin 2 is equipped with a drying tray 5, the drying tray 5 is installed on the top of the drying bin 2, the interior of the drying tray 5 is hollow, the lower surface of the drying tray 5 is distributed with air holes, and the outlet of the hot air blower 4 The tuyere is communicated with the drying pan 5 through a pipeline, and the hot air is eject...

Embodiment 2

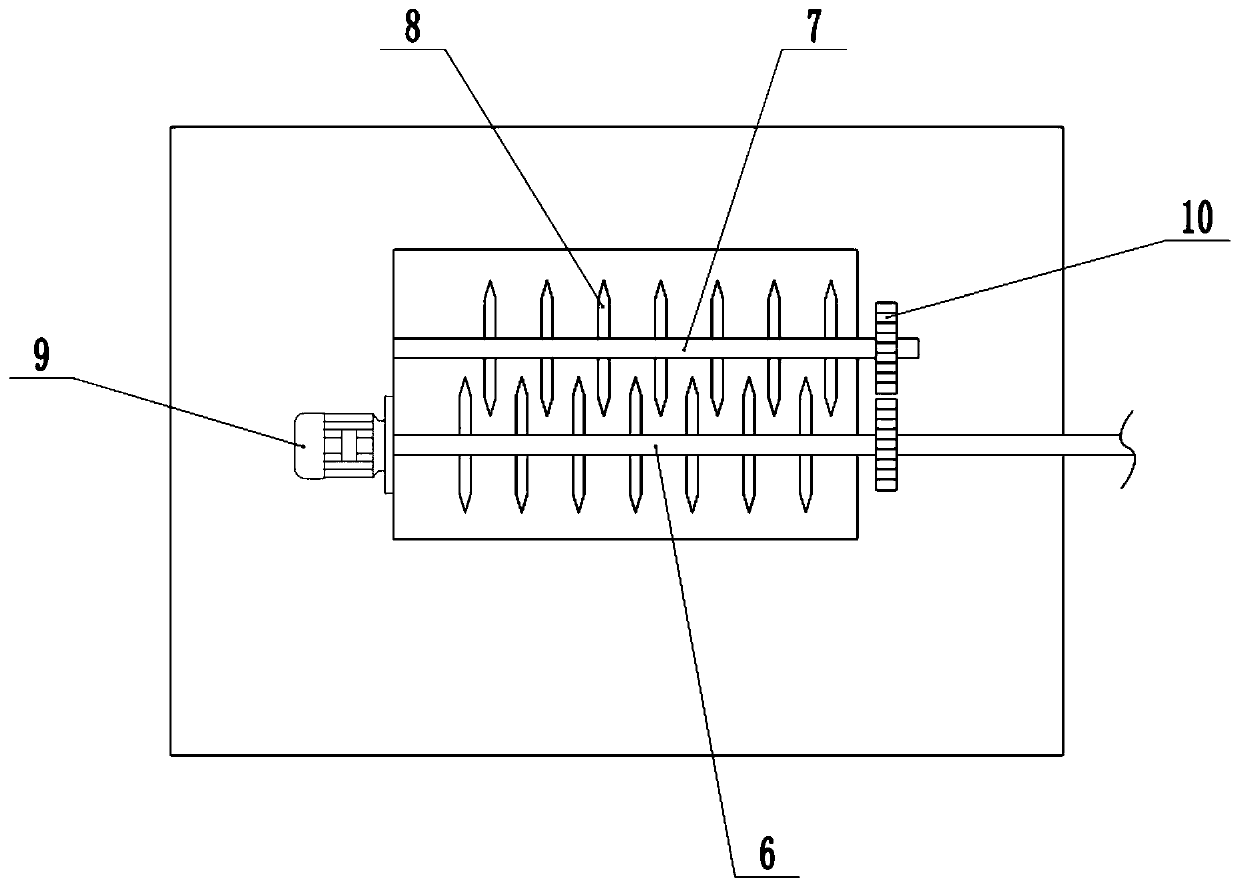

[0025] see image 3 , on the basis of embodiment 1, the interior of drying chamber 2 is equipped with a cutting mechanism, and the cutting mechanism includes a driving shaft 6, a driven shaft 7, a crushing blade 8, a driving motor 9 and a gear set 10, the driving shaft 6, The end of driven shaft 7 is respectively connected with the side wall of drying bin 2 in rotation, and the outer side wall of drying bin 2 is fixedly connected with driving motor 9, and the shaft extension end of driving motor 9 is connected with driving shaft 6, and driving shaft 6 1. The driven shaft 7 is connected through the gear set 10, the driving shaft 6 and the driven shaft 7 are staggered with crushing blades, and the driving motor 9 drives the driving shaft 6 to rotate when it is running, and then drives the driven shaft 7 to rotate synchronously through the gear set 10 , use the crushing blade 8 to cut the forage into sections, and preliminarily crush the forage, and at the same time, prevent the ...

Embodiment 1、 Embodiment 2

[0026] In combination with Embodiment 1 and Embodiment 2, the working principle of the present invention is: put the forage grass to be processed into the drying bin 2 through the feeding port 3, start the hot air blower 4, and the hot air is ejected through the air holes on the drying disc 5, to The pasture is dried, and the drive motor 9 is started to drive the driving shaft 6 to rotate, and then the driven shaft 7 is driven to rotate synchronously through the gear set 10. The pasture is cut into sections by the crushing blade 8, and the pasture is initially crushed. The section mechanism prevents the forage grass from being blocked in the drying bin 2. The sectioned forage grass falls between the upper knife rest 11 and the lower knife rest 12. When the driving shaft 6 rotates, it drives the crankshaft 14 to rotate, thereby driving the upper knife rest 11. 1. The lower knife rest 12 reciprocates in the horizontal direction, and the moving directions of the upper knife rest 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com