Joint core for joining column and beam, and method for joining column and beam using same

A technology for connecting columns and cores, applied in building types, buildings, protective buildings/shelters, etc., can solve problems such as high manufacturing costs, limitations on the applicability of CFT structures, and practical implementation limitations, to shorten the construction period, The effect of realizing economical effect and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Drawings Hereinafter, the present invention is described in detail with reference to the accompanying drawings.

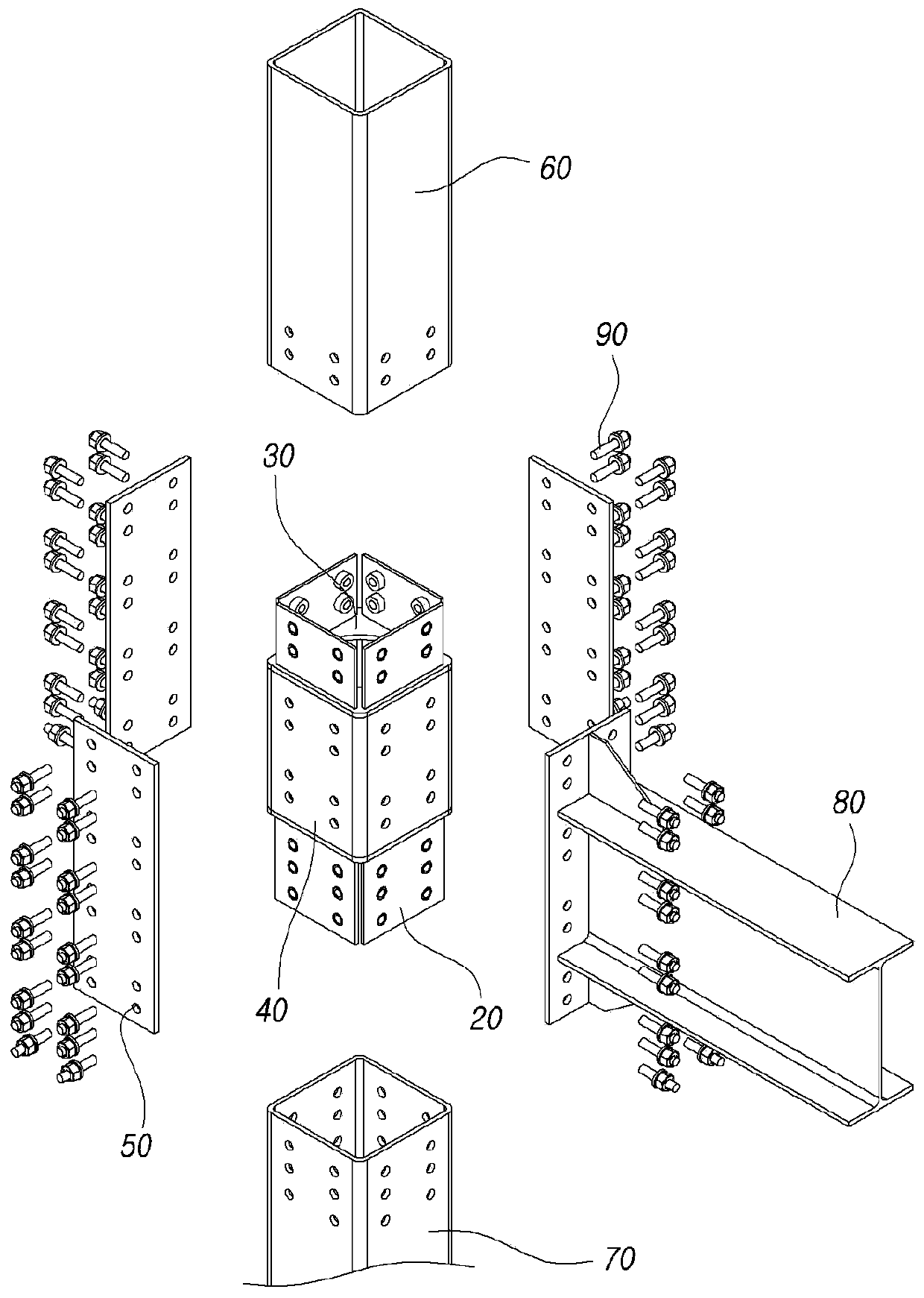

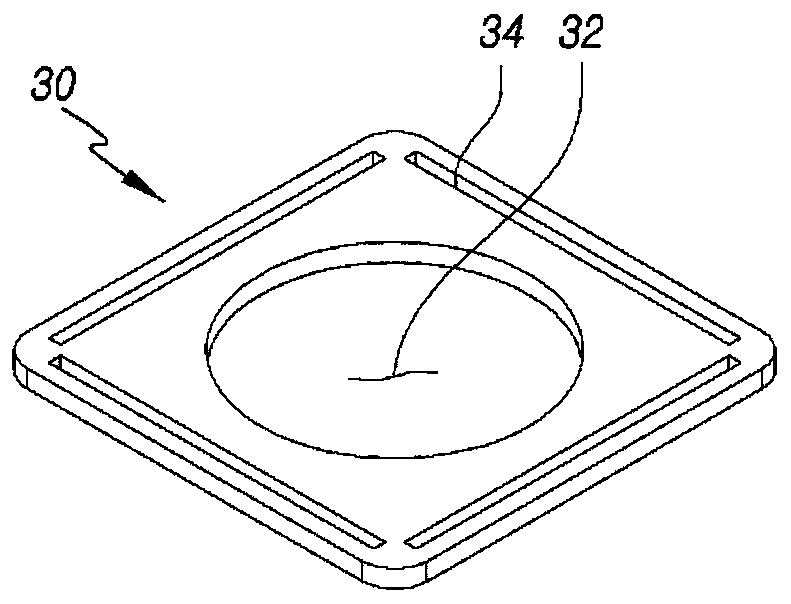

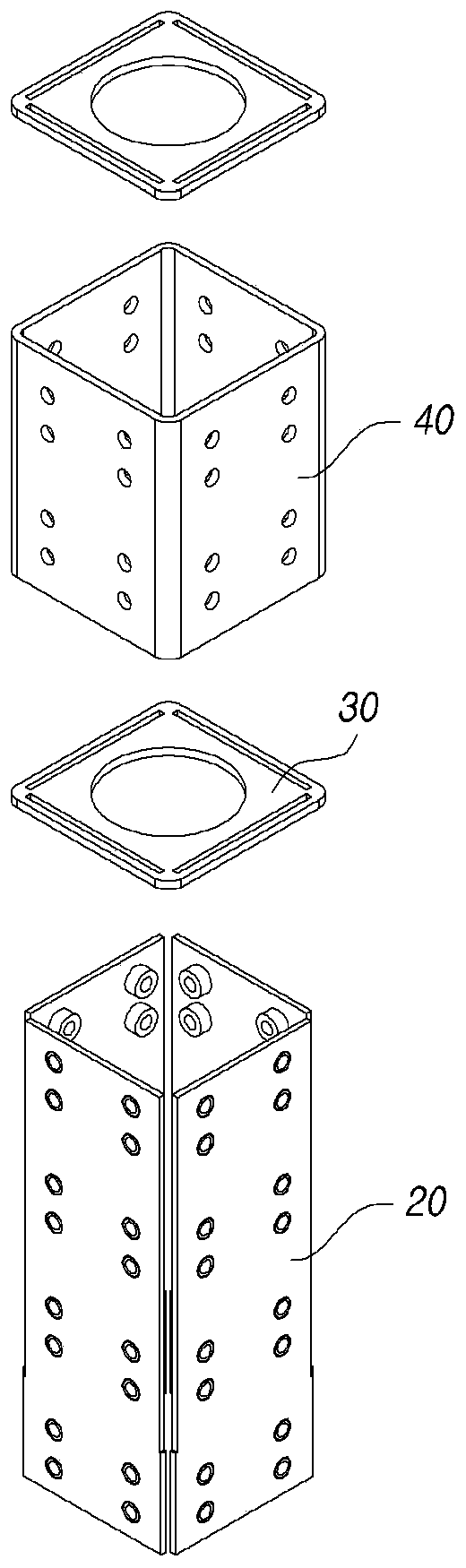

[0076] figure 1 An exploded perspective view showing the concept of combining columns and beams using a node core according to the first embodiment of the present invention, figure 2 is the perspective view of the partition, image 3 An exploded perspective view of the node core.

[0077] exist Figure 1 to Figure 3 , the node core 10 includes an internal stiffener 20 , a bulkhead 30 and an intermediate column 40 .

[0078] The internal reinforcement member 20 is steel and formed in a plate shape. In the first embodiment, the internal reinforcement members 20 are four in total and are respectively coupled to the inner sides of a rectangular steel pipe-shaped center column 40 which will be described below. A plurality of holes for bolting may be formed on the inner reinforcement member 20 . In addition, a protrusion for bolting may be formed inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com