Product assembling safety floating device

A floating device and safe technology, applied in the direction of assembling printed circuits with electrical components, electrical components, printed circuit manufacturing, etc., can solve the problems of PCB board or product damage, the impact force of the PCB board is easy to be too large, etc., to achieve a safe assembly method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

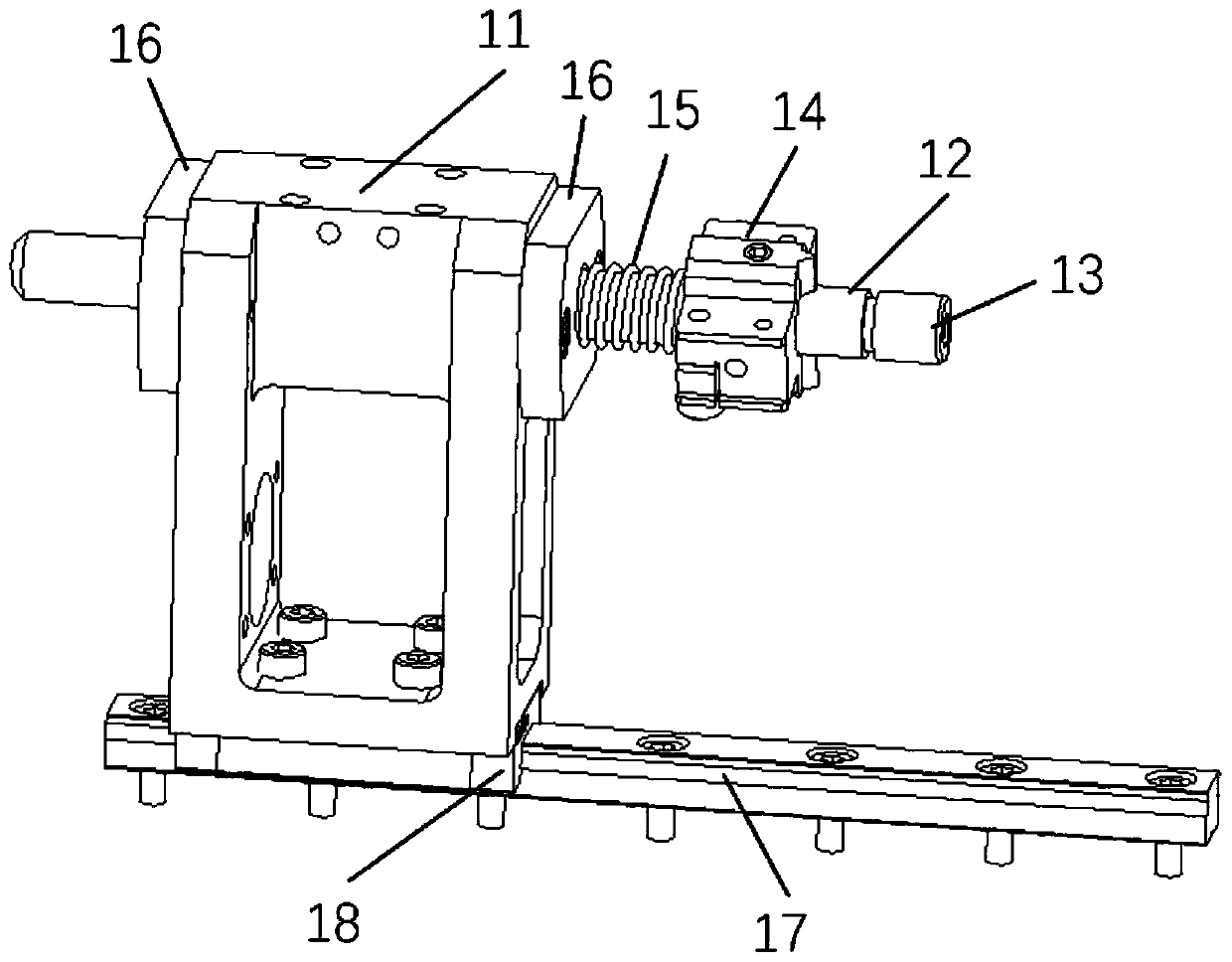

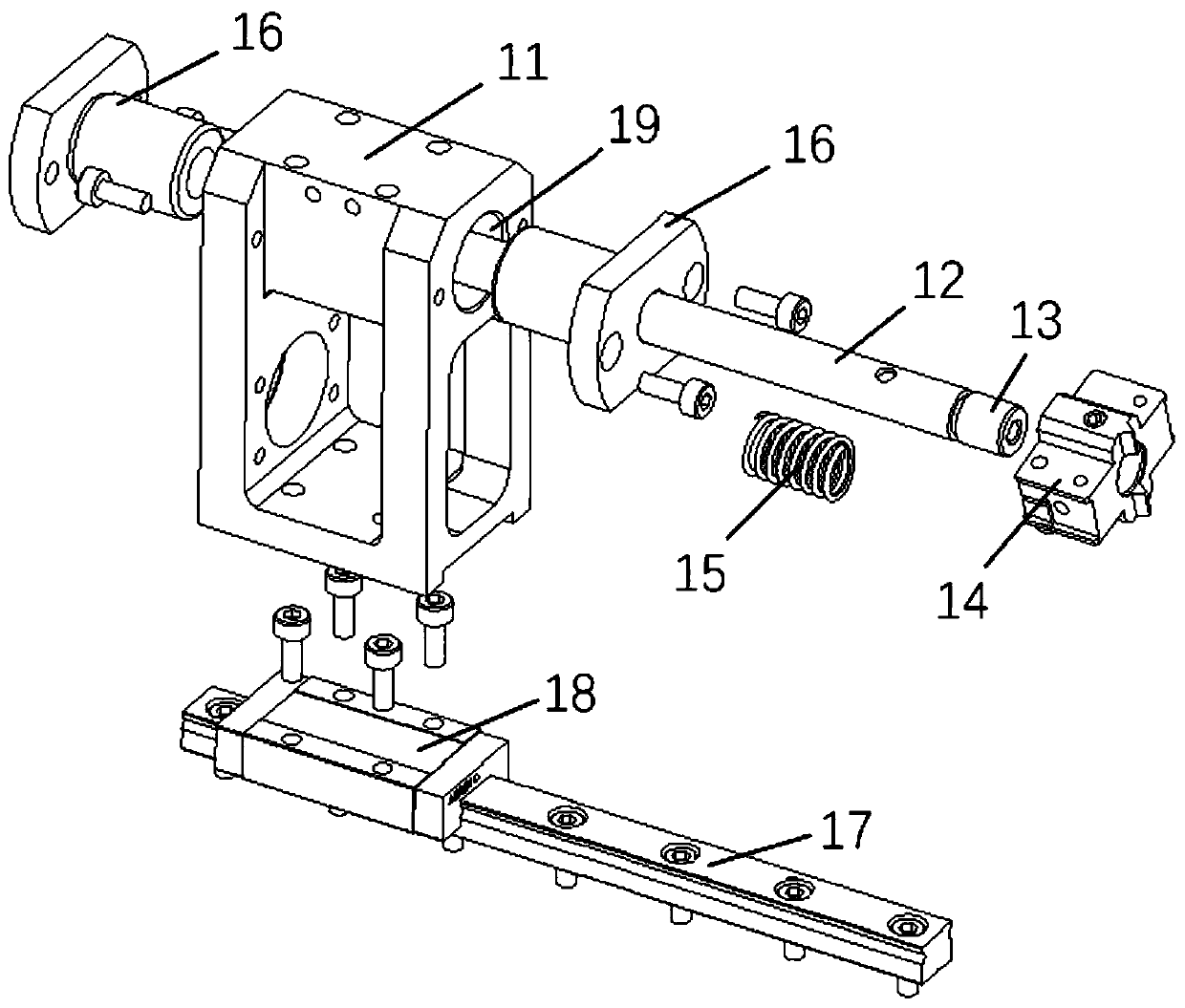

[0028] see figure 1 with figure 2 shown.

[0029] This embodiment provides a safety floating device for product assembly, which includes an inserting drive unit (not shown in the figure) and a sliding seat 11 , and the inserting drive unit is drivingly connected to the sliding seat 11 .

[0030] The sliding seat 11 is provided with a guide hole 19 , and a working shaft 12 is pierced in the guiding hole 19 , and an installation base 13 is fixedly mounted on one end of the working shaft 12 . Wherein, the mounting base 13 is used as a carrier of a suction cup or a chuck, and the product is temporarily fixed on the suction cup or the chuck, and then inserted into the PCB board.

[0031] A limit block 14 is fixed on the working shaft 12, an elastic element 15 is arranged between the limit block 14 and the sliding seat 11, and the two ends of the elastic element 15 are respectively connected with the sliding seat 11 and the limit Block 14 is permanently connected.

[0032] Spec...

Embodiment 2

[0036] see figure 1 with figure 2 shown.

[0037] On the basis of Embodiment 1, the elastic element 15 is sleeved on the working shaft 12, so that the elastic element 15 is limited between the sliding seat 11 and the limit block 14, which can reduce the space occupied by the elastic element 15 , improve the rationality of the overall structure.

Embodiment 3

[0039] see figure 1 with figure 2 shown.

[0040] On the basis of the first embodiment, linear bearings 16 are fixedly installed at both ends of the guide hole 19 , and the working shaft 12 passes through the linear bearings 16 . This linear bearing 16 plays a guiding role when the working shaft 12 slides in the guide hole 19 to improve its accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com