Dynamic reliability assessment method for coupling fault of middle trough of scraper conveyor

A scraper conveyor, coupling fault technology, applied in the direction of conveyor, conveyor object, conveyor control device, etc., can solve the problems of inability to describe asymmetric probability-related properties, inability to apply small sample conditions, etc., to improve flexibility performance, improved accuracy, improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

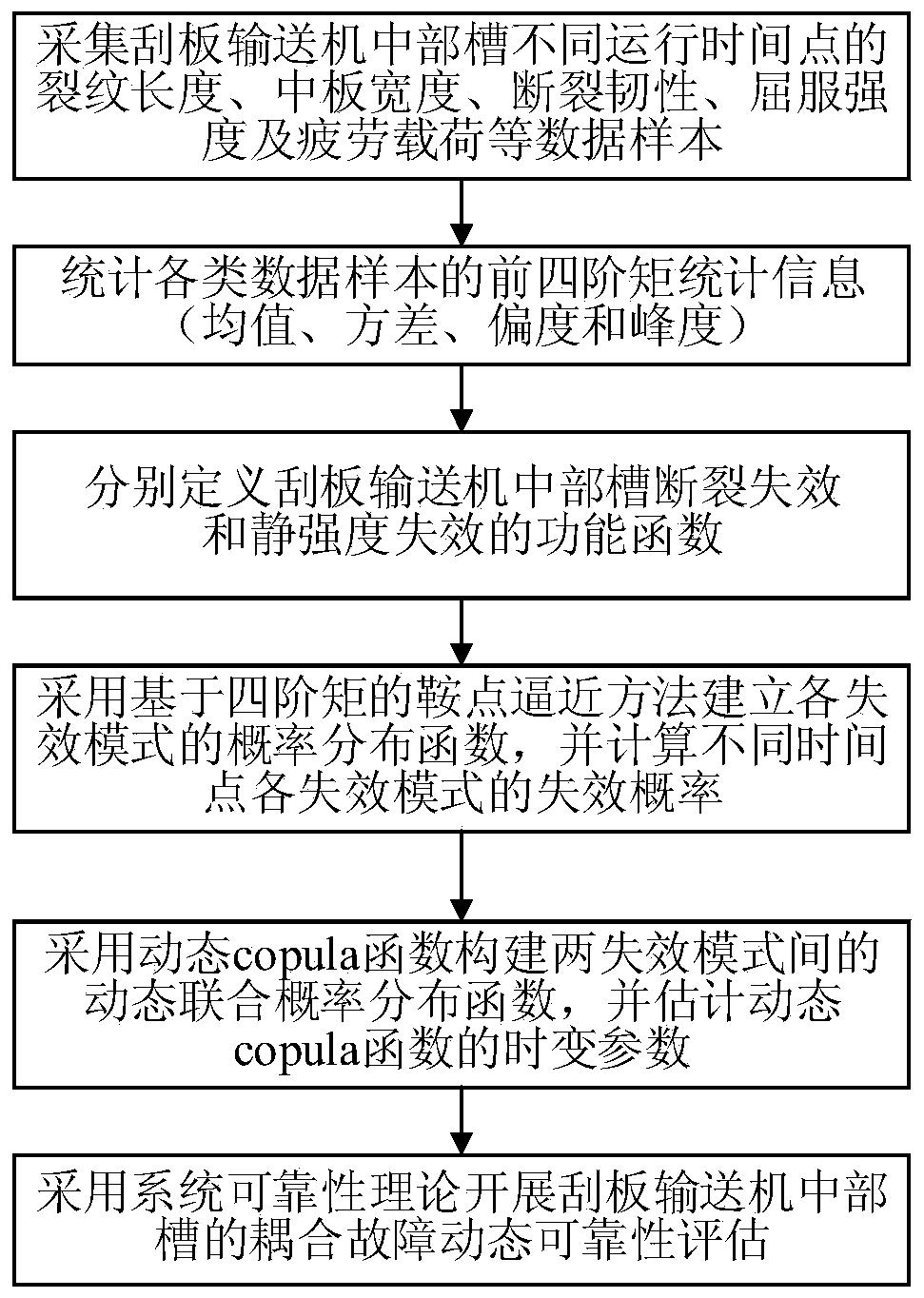

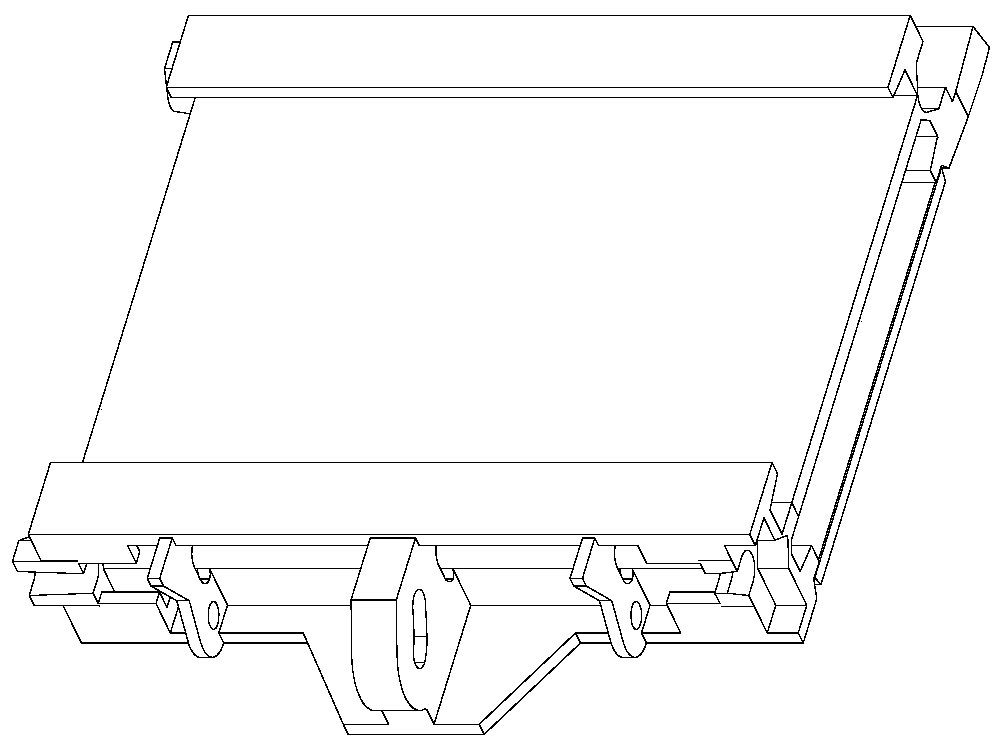

[0060] In order to understand more fully the characteristics and engineering applicability of this invention, the present invention aims at such as figure 2 The structure of the middle trough of the scraper conveyor is shown, and the dynamic reliability evaluation of the coupling fault is carried out.

[0061] (1) Collect the data samples (crack length, middle plate width, fracture toughness, yield strength and fatigue load, etc.) of the fracture failure and static strength failure of the middle groove of the scraper conveyor at different time points, and obtain the first four samples of each sample. Moment probability information.

[0062] (2) According to the safety criteria of fracture failure and static strength failure of the middle trough of the scraper conveyor, respectively establish its reliability function function under fracture failure and static strength failure, namely

[0063] g 1 =K IC -K max

[0064] g 2 =Q-S

[0065] Among them, K IC is the fracture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com