Rotatable electric slit

A slit and electric technology, applied in the field of optical slits, can solve the problems that optical slits cannot be slit direction and adjustment, and achieve the effect of simple structure, easy operation and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

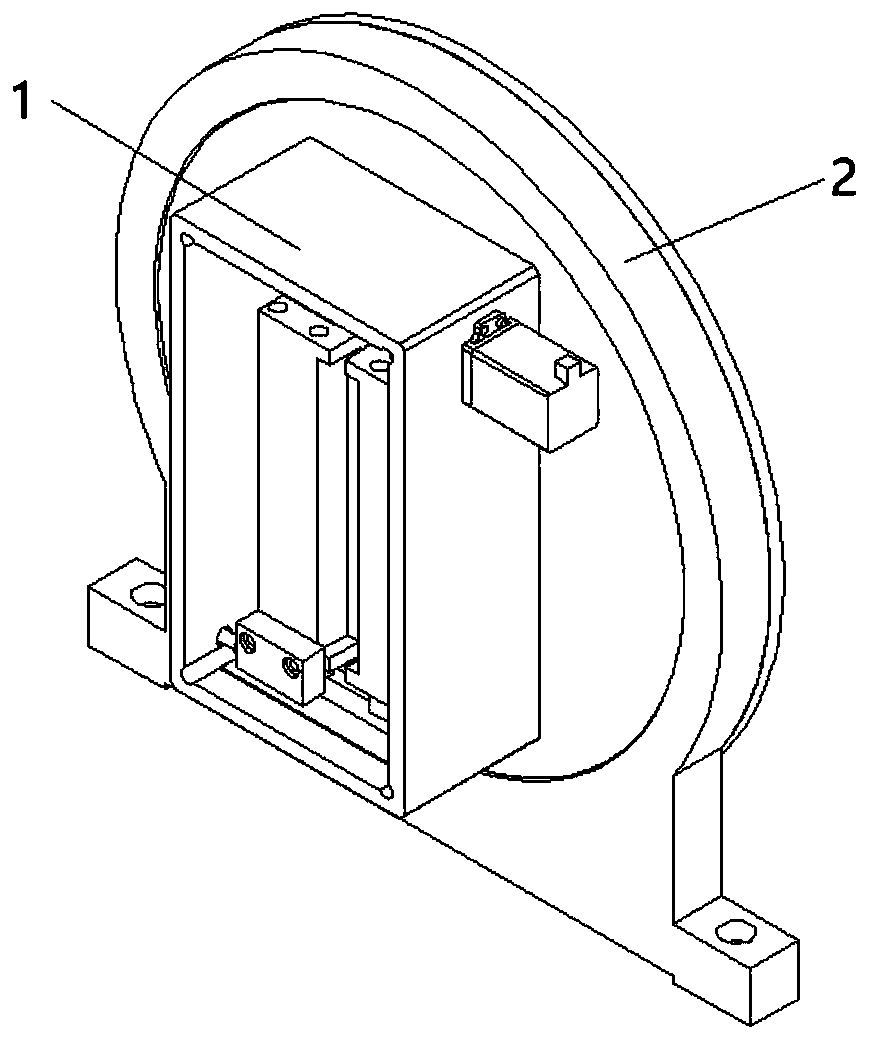

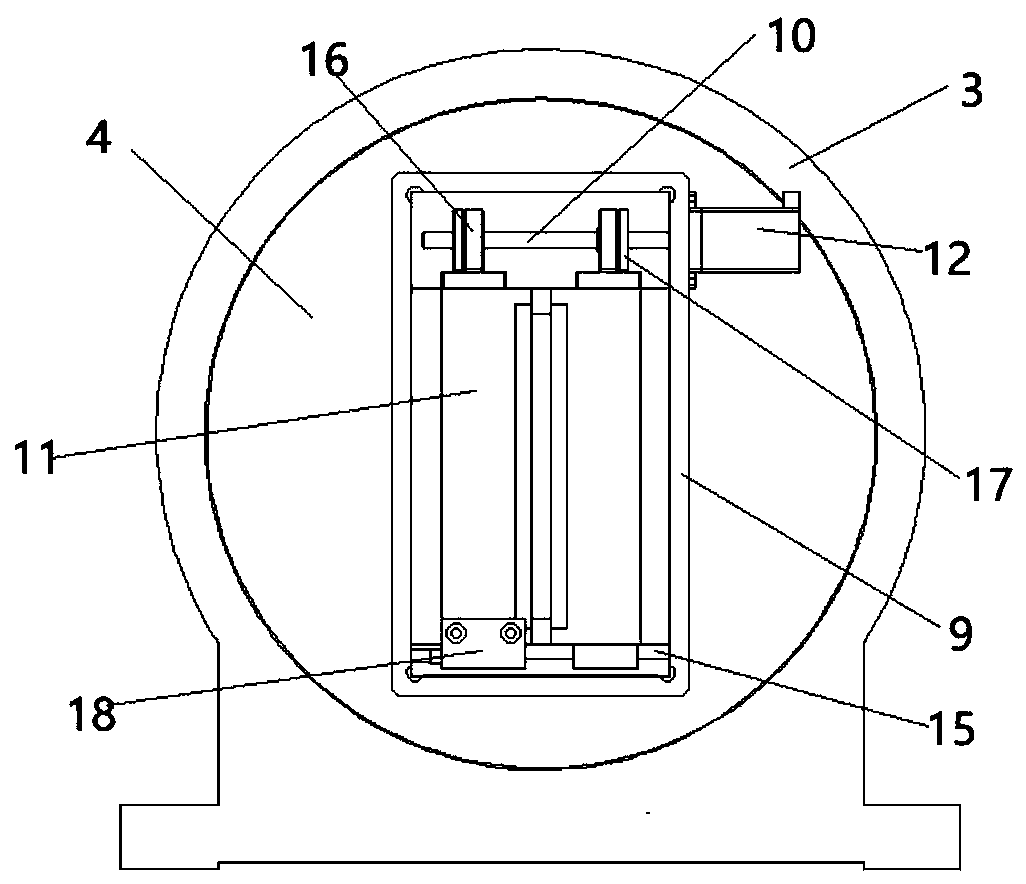

[0045] A rotatable electric slit in this embodiment, combined with figure 1 , figure 2 , image 3 as well as Figure 4 As shown, it includes an electric slit device 1 and a direction adjustment device 2;

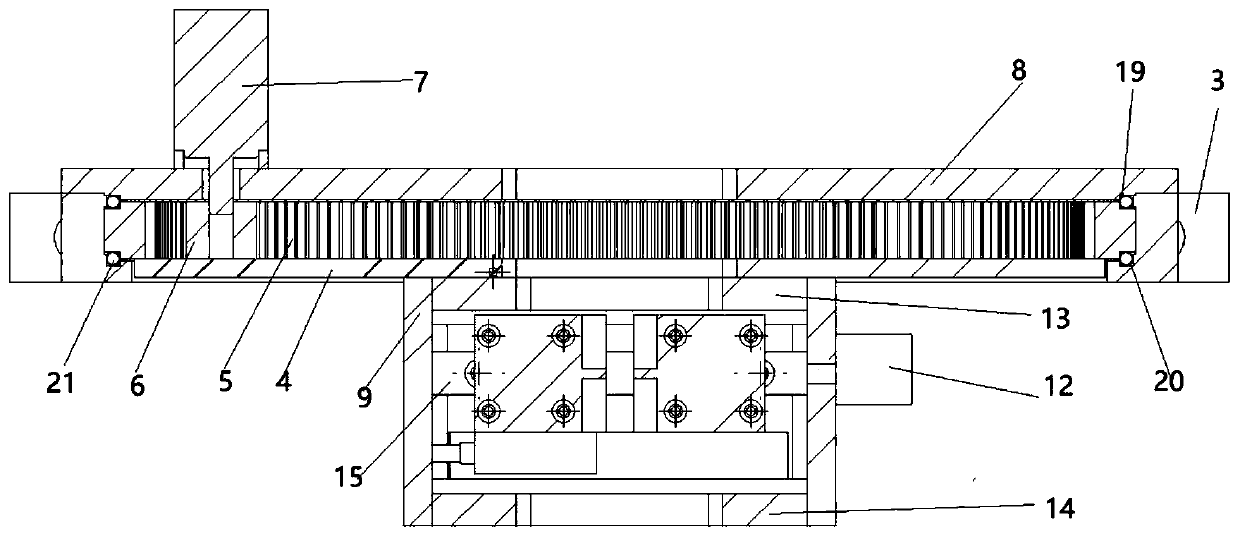

[0046] The direction adjusting device 2 includes an annular seat 3, a fixed plate 8, a rotating plate 4, an inner ring gear 5, a driving gear 6 and a first stepping motor 7;

[0047] The fixed plate 8 is fixedly installed on one end of the annular seat 3, and the rotating plate 4 is located at the other end of the annular seat 3, so that a circular cavity is formed between the annular seat 3, the fixed plate 8 and the rotating plate 4; the ring gear 5 and the annular The seat 3 is coaxial and located in the circular cavity, and a bearing assembly is arranged between the outer surface of the ring gear 5 and the inner surface of the ring seat 3; one end face of the rotating plate 4 is fixedly connected with the ring gear 5, and the other end face An electric slit device 1...

Embodiment 2

[0059] combine figure 1 , figure 2 , image 3 as well as Figure 4 As shown, the structure of the rotatable electric slit in this embodiment is basically the same as that in Embodiment 1, and the main difference is that the electric slit device includes a housing 9, a double screw screw 10, two slit doors 11 and a second slit. Two stepper motors 12;

[0060] The housing 9 includes a hollow frame formed by connecting four rectangular plates end to end, and a front end cover 13 and a rear end cover 14 arranged on the hollow frame; Adapted through holes; guide rails 15 are installed on the bottom inner wall of the hollow frame, and a double-rotation screw 10 is installed on the top of the hollow frame. Nuts 16 are installed on the right-handed and right-handed thread sections; one end of the two slit doors 11 is clamped on the guide rail 15, and the other ends are respectively connected to the two nuts 16 through nut seats 17, and a slit is formed between the two slit doors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com