Ice making evaporator and processing method thereof

An ice-making evaporator and processing method technology, applied in evaporator/condenser, ice making, ice making, etc., can solve the problems of small evaporation area and low work efficiency, achieve increased evaporation area, convenient installation and production, The effect of high ice making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Below in conjunction with accompanying drawing this embodiment is described in detail:

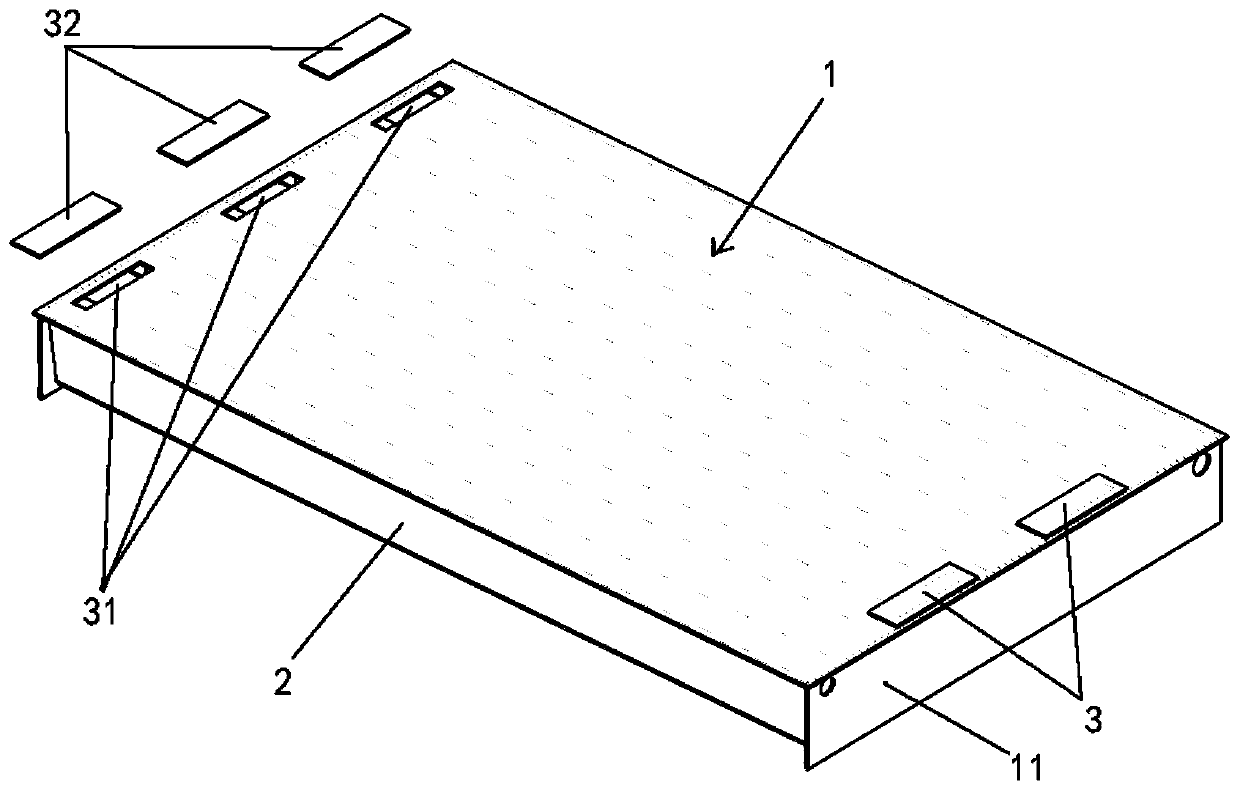

[0053] This embodiment provides as Figure 1-7 An ice-making evaporator is shown, comprising:

[0054] Chassis 1;

[0055] There are multiple partitions 4, which are arranged on the chassis 1 to form ice trays 5;

[0056] The evaporating pipeline device includes a plurality of evaporating tubes 2 arranged on the base plate 1, and a plurality of evaporating tubes 2 are located on the side of the base plate where the ice-making tray 5 is located.

[0057] In the above embodiment, several evaporating tubes 2 have flowing refrigerant gas inside, and by arranging several evaporating tubes 2 on the side of the chassis 1 where the ice-making tubes are located, the evaporating tubes are in direct contact with the side of the corresponding ice-making tray. Or it can be used as the side of the ice-making tray, so that the sides of the ice-making tray 5 can be refrigerated by multiple evapo...

Embodiment 2

[0071] This embodiment provides a processing method for making an ice-making evaporator as described in Embodiment 1. The following components are preferably made of stainless steel. Refer to Figure 8 , including the following steps:

[0072] Make the chassis 1 of U-shaped structure;

[0073] A plurality of evaporation tubes 2 connected at intervals and in a V-shaped structure are made;

[0074] A plurality of partitions 4 that are matched and connected with the evaporation tube 2 are made;

[0075] A plurality of the evaporation tubes 2 are integrally fixed on the chassis 1 by welding, and the two ends of the plurality of the evaporation tubes 2 are sealed and welded to the two baffles 11 at the two ends of the chassis 1; The evaporating tubes 2 are fused in a vertically intersecting manner to form several ice-making trays 5 .

[0076] In the above processing method, the evaporating tube 2, the chassis 1 and the partition plate 4 are respectively manufactured first, and t...

Embodiment approach

[0077] As a preferred embodiment, the processing method of ice-making evaporator also includes the following steps:

[0078] Make some ventilation holes 31 communicated with one or both ends of several evaporating tubes 2 on the chassis 1; The order is correspondingly welded to the bottom of the chassis and covers the two adjacent ventilation holes 31 in turn, so that several of the evaporation tubes 2 are sequentially connected to form a continuous ventilation pipeline; The two mounting holes connected at one end of the evaporating tube are respectively welded into the inlet pipe 6 and the outlet pipe 7 in the two mounting holes. In this manufacturing method, a plurality of the evaporating tubes 2 are sequentially connected to each other through a plurality of sealing covers. Together, a circulation pipeline for the refrigerant to flow continuously between several evaporator tubes is formed on the chassis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com