Cam shaft

A camshaft and cam technology, which is applied to cams, shafts, couplings, etc., can solve the problems of low camshaft utilization, increased cost, and cam wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

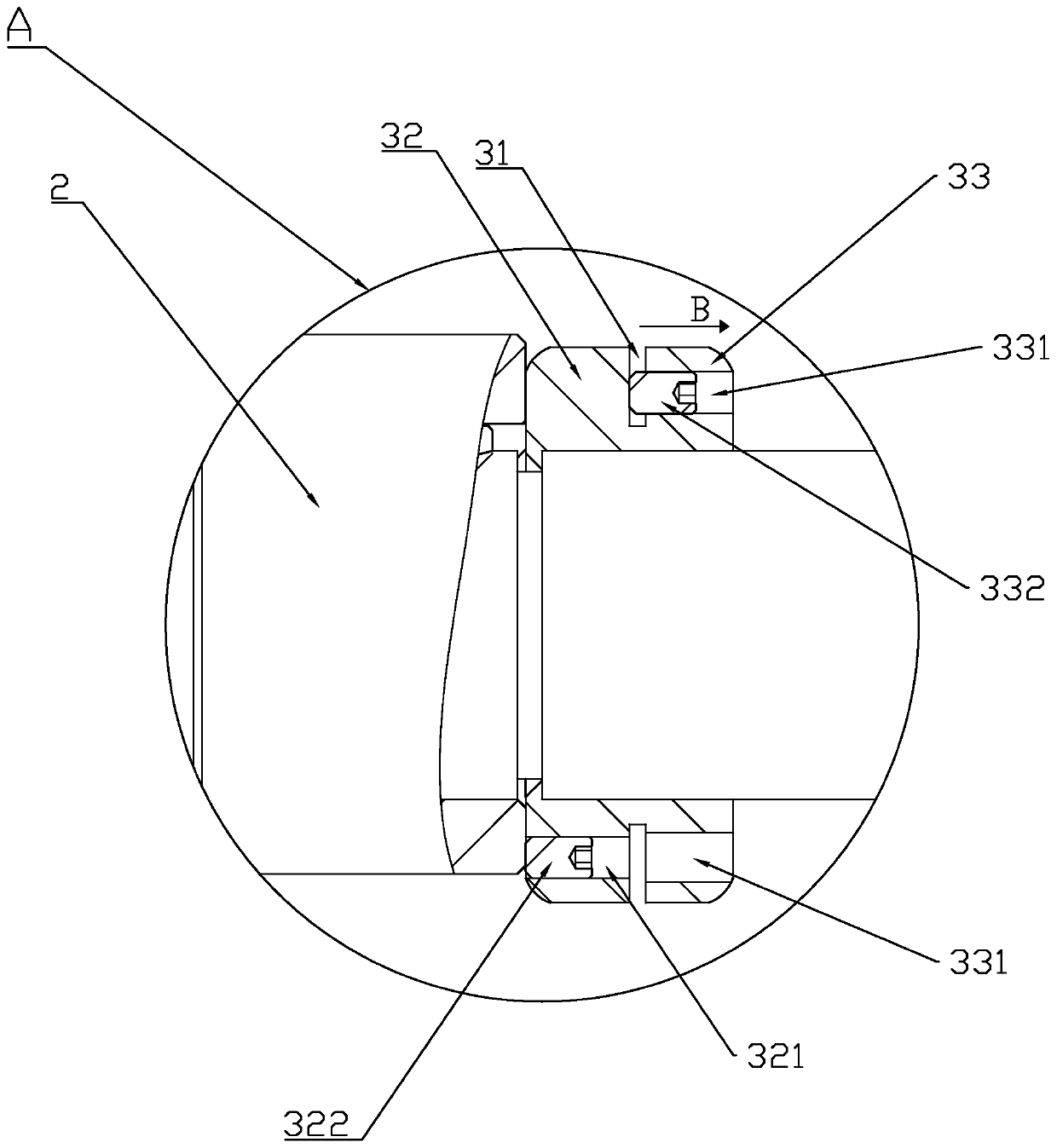

[0016] image 3 The direction of the middle arrow B is the direction of the reaction force on the second fastening block 33

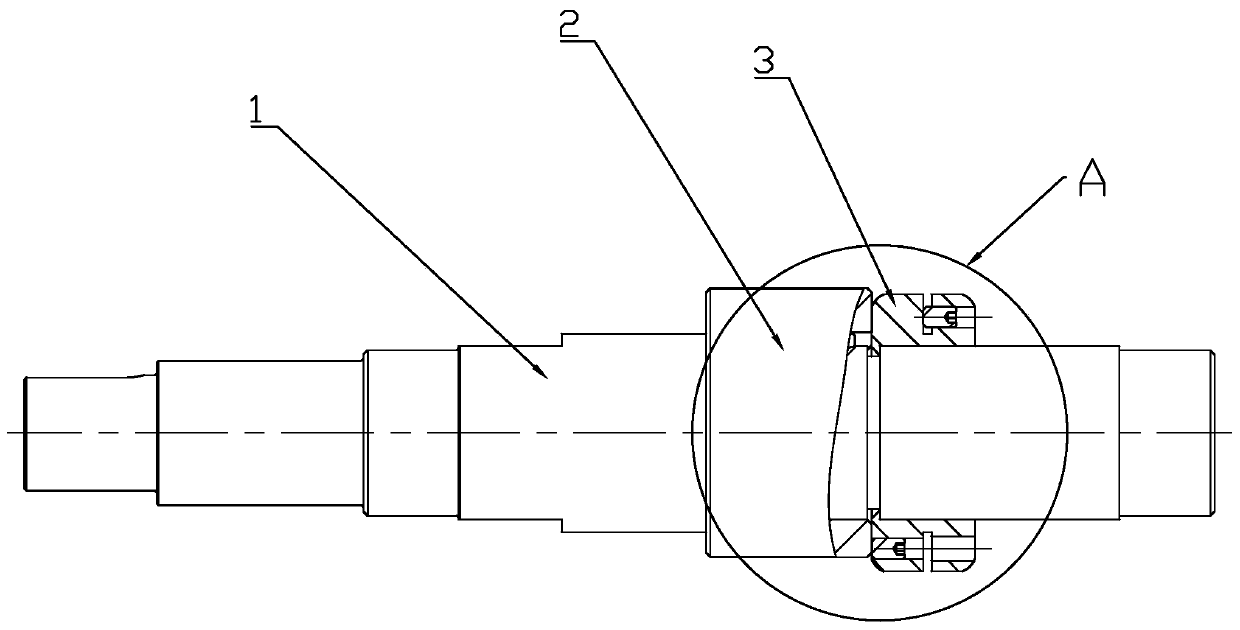

[0017] Depend on Figure 1 to Figure 6 It can be seen that the present invention discloses a camshaft, which includes a support shaft 1 and a cam sleeve 2. The support shaft 1 includes a threaded section 11, a cam installation section 12, and an interference section 13 arranged in sequence. The interference section 13 and the The junction of the cam installation section 12 is formed with a conflicting step 14, the cam sleeve 2 is movably sleeved on the cam installation section 12, the threaded section 11 is screwed with a fastening nut 3, one end of the cam sleeve 2 is in contact with the The step 14 is in conflict, and the other end is in conflict with the fastening nut 3 to realize the fixing of the cam sleeve 2 on the support shaft 1 . The cam sleeve 2 is movably sleeved on the support shaft 1, and the fastening nut 3 is screwed into the threaded s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com