Ink supply system of sealing machine

A stamping machine and ink supply technology, which is applied in the field of stamping machines, can solve the problems of consumption, affecting the progress of stamping, and the inconvenience of stamping, and achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

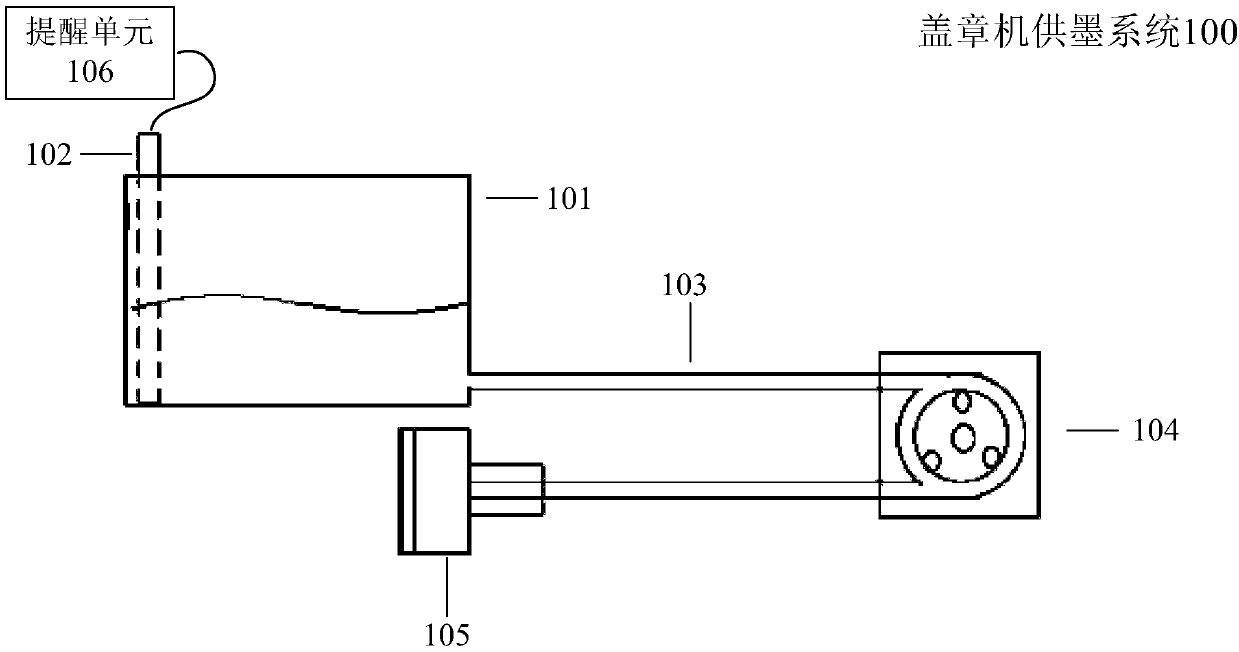

[0026] figure 1 It is a schematic diagram of the mechanical structure of the ink supply system 100 of the stamp stamping machine of the present invention. The ink supply system 100 of the stamping machine includes an ink storage box 101 , a liquid level sensor 102 , an ink delivery mechanism 103 , an ink delivery controller 104 , a stamp 105 and a reminder unit 106 .

[0027] The ink storage box 101 may store ink. The ink storage box 101 includes a liquid level sensor 102 . The liquid level sensor 102 is located inside the ink storage box, contacts with the ink inside the ink storage box 101 , and is used for detecting the liquid level of the ink in the ink storage box 101 .

[0028] The ink delivery mechanism 103 is connected to the ink storage box 101 . The ink delivery mechanism 103 can be connected to the bottom of the ink storage box 101 or the middle of the ink storage box 101 for transferring the ink stored in the ink storage box 101 to the stamp 105 . Preferably, th...

Embodiment 2

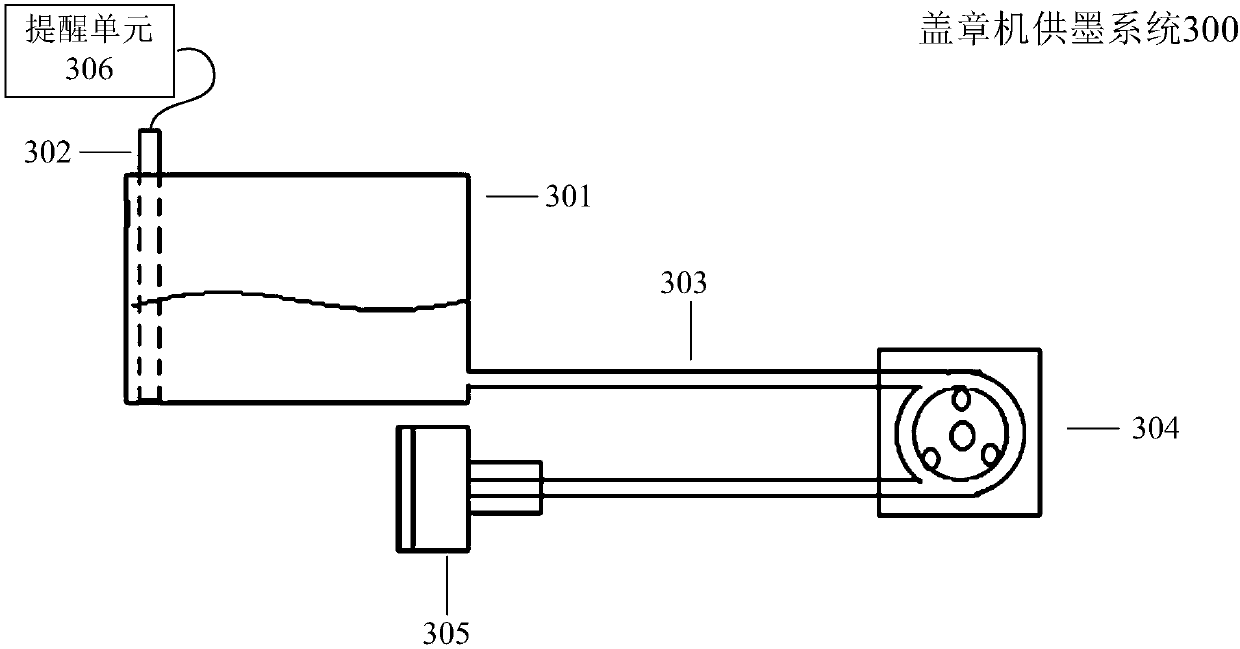

[0039] image 3 It is a schematic diagram of the mechanical structure of the ink supply system 300 of the stamp stamping machine of the present invention. The ink supply system 300 of the stamping machine includes an ink storage box 301 , a liquid level sensor 302 , an ink delivery mechanism 303 , an ink delivery controller 304 , a stamp 305 and a reminder unit 306 .

[0040]The ink storage box 301 may store ink. The ink storage box 301 includes a liquid level sensor 302 . The liquid level sensor 302 is located inside the ink storage box 301 , contacts with the ink inside the ink storage box 301 , and is used for detecting the liquid level of the ink in the ink storage box 301 .

[0041] The ink delivery mechanism 303 is connected to the ink storage box 301 . The ink delivery mechanism 303 can be connected to the bottom of the ink storage box 301 or the middle of the ink storage box 301 for transferring the ink stored in the ink storage box 301 to the stamp 305 . Preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com