A multi-axis rigid-flexible coupling motion platform

A motion platform, rigid-flexible coupling technology, applied in the direction of workbench, metal processing equipment, metal processing machinery parts, etc., can solve problems such as fracture, mechanism crack, limited application, etc., achieve large working area, low cost, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

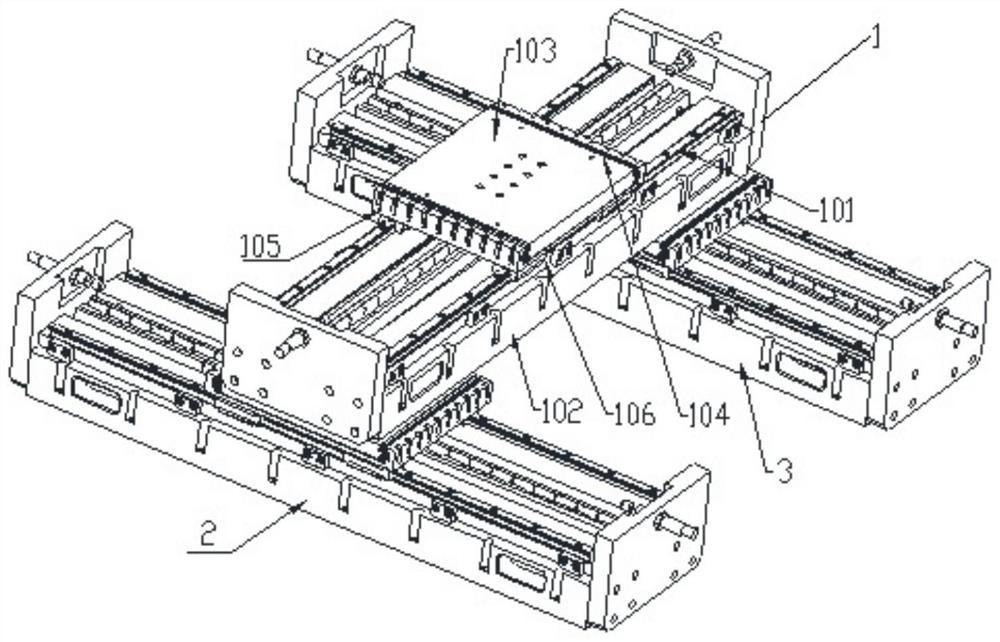

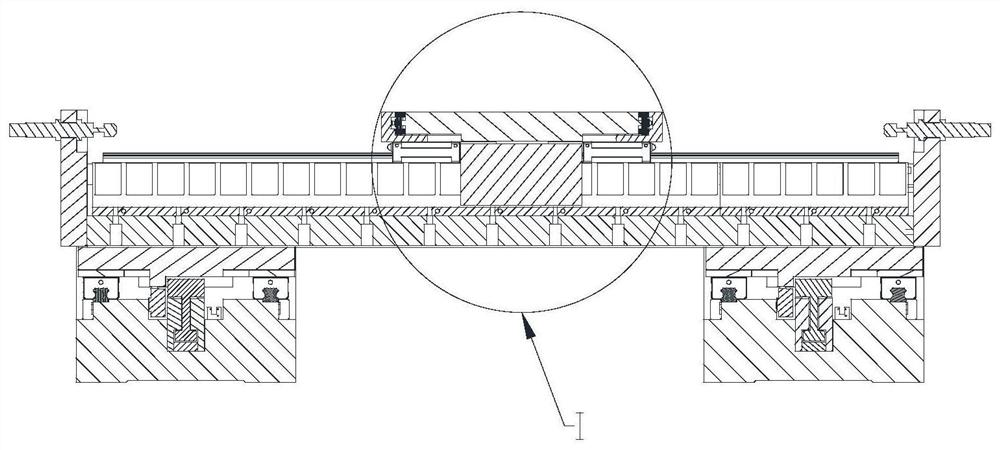

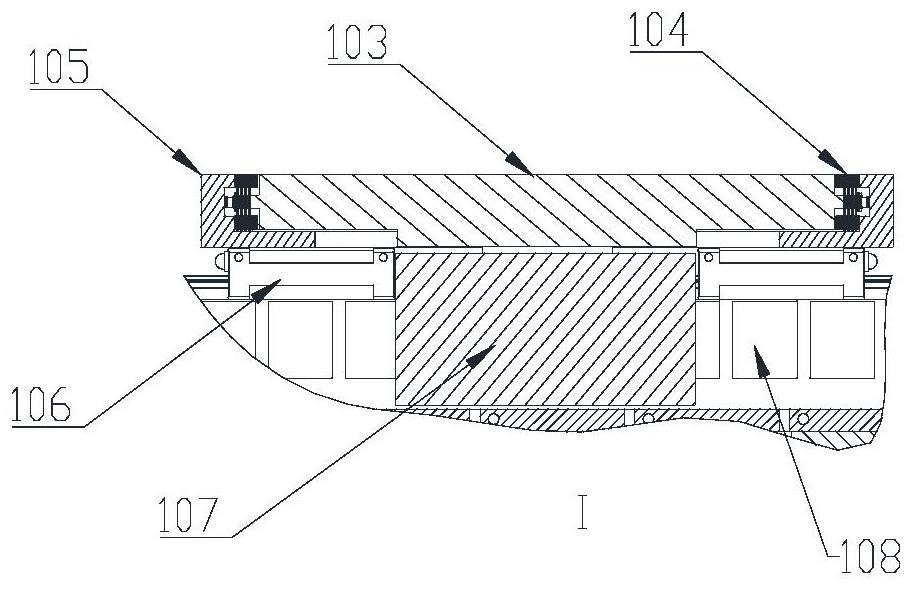

[0033] Such as Figure 1-3 As shown, a multi-axis rigid-flexible coupling motion platform, the multi-axis rigid-flexible coupling motion platform includes: three single-axis rigid-flexible coupling motion platforms, respectively the first single-axis rigid-flexible coupling motion platform 1, the second single-axis Rigid-flexible coupling motion platform 2 and the third single-axis rigid-flexible coupling motion platform 3, each single-axis rigid-flexible coupling motion platform includes: linear guide rail 101, base 102, core motion platform 103, bearing rigidity enhanced flexible hinge group 104 , The rigid frame 105 of the motion platform, the linear guide rail slider 106, the first driver 107 (ie, the linear motor mover), and the linear motor stator 108 (magnetic block). Among them, the core motion platform 103, the bearing rigidity enhanced flexible hinge group 104 and the motion platform rigid frame 105 form a rigid-flexible coupling platform; the first driver 107 (ie, t...

Embodiment 2

[0039] Example two such as Figure 11-12 As shown, it is also a multi-axis rigid-flexible coupling motion platform, including: two single-axis rigid-flexible coupling motion platforms: a first single-axis rigid-flexible coupling motion platform and a second single-axis rigid-flexible coupling motion platform. The structure of each single-axis rigid-flexible coupling motion platform is the same as that of the single-axis rigid-flexible coupling motion platform in Embodiment 1, including: the first core motion platform B1, the first rigid frame of the motion platform B2, the first bearing rigidity enhanced flexibility Hinge group B3, first linear guide rail B4, first linear guide rail slider B5, first base B6, first linear motor stator (magnetic block) B13, second bearing rigidity enhanced flexible hinge group B7, second Core motion platform B8, second motion platform rigid frame B9, second base B10, second linear guide rail slider B11, second linear guide rail B12, second linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com