Magnetic tape recording and/or reproduction apparatus and its reel braking mechanism

A tape recording and braking mechanism technology, which is applied in the direction of record carrier drive mechanism, data recording, recording information storage, etc., can solve the problems of non-static, tape slack, etc., and achieve the effect of small overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach - pic 1 to 3

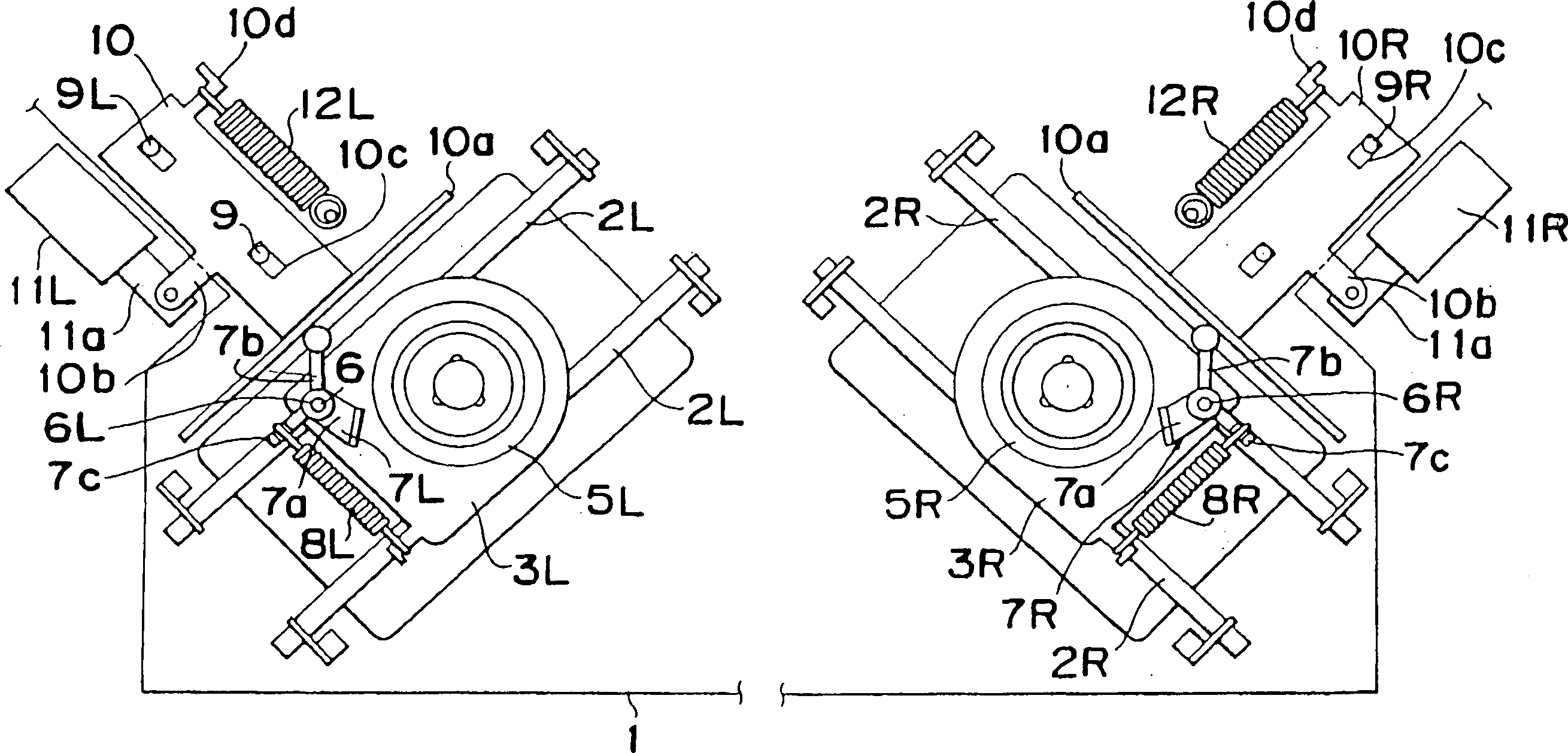

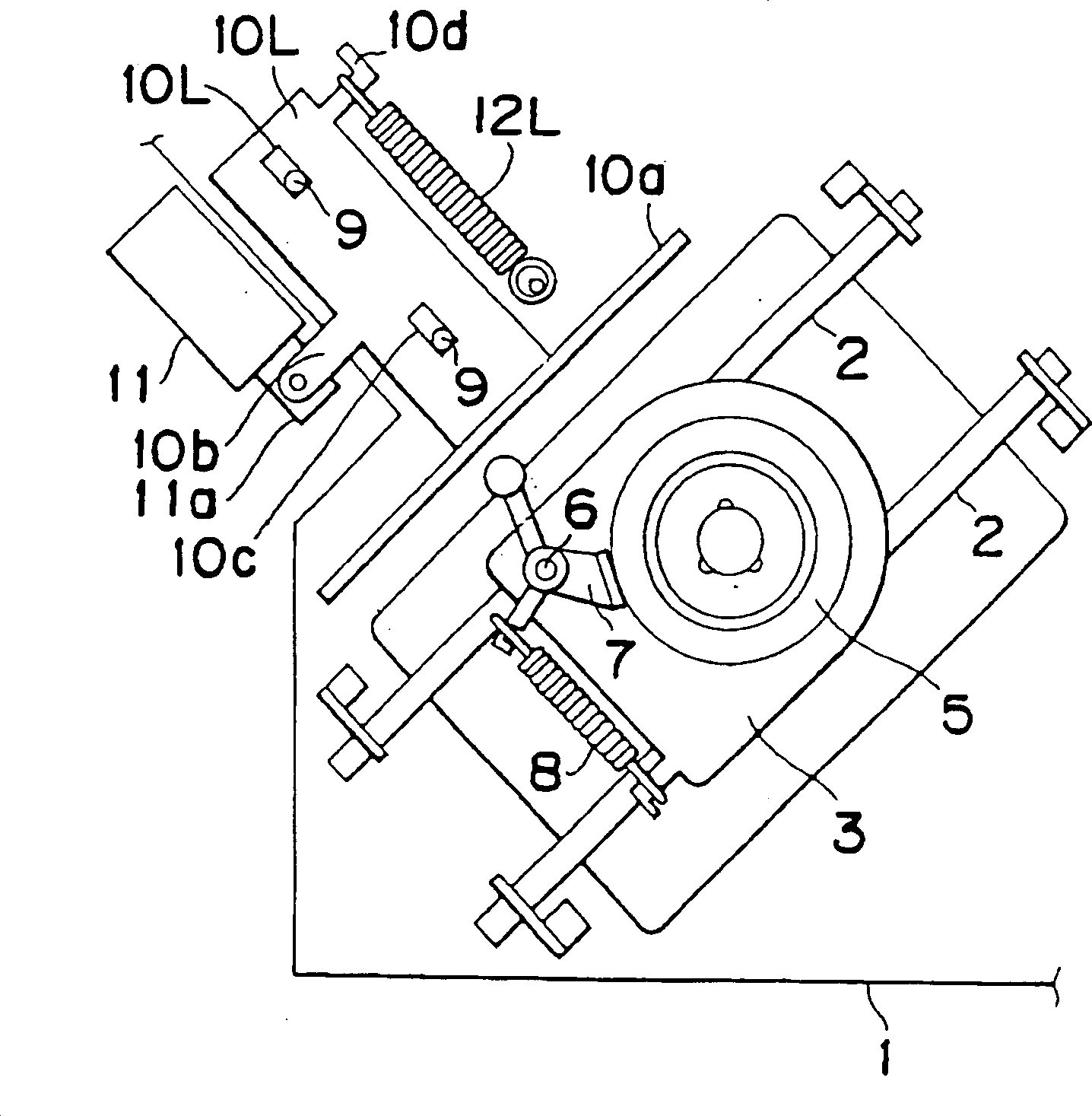

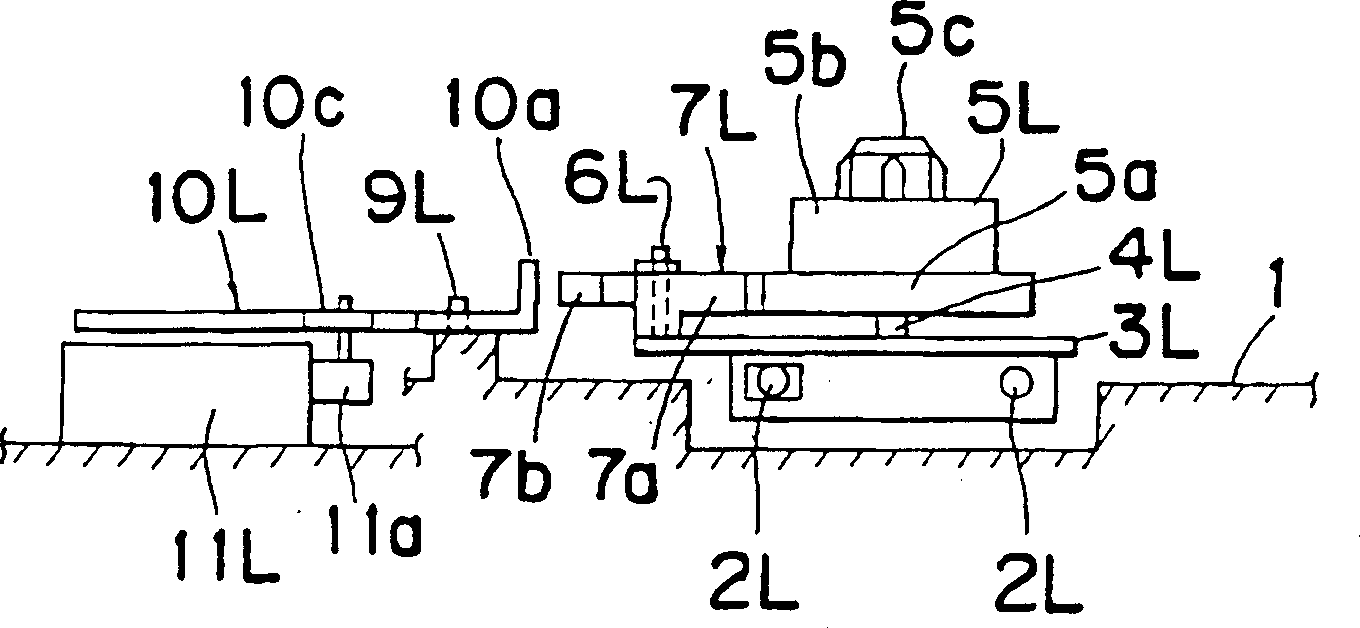

[0045] figure 1 A video recorder shown in includes a reel support bottom case 1 on which two pairs of parallel guide rods 2 are mounted. One pair of parallel guide rods 2L and the other pair of parallel guide rods 2R are mounted on the bottom case 1 so as to intersect at an imaginary straight line away from the corresponding rotation axes connecting the supply reel 5L and the take-up reel 5R.

[0046] The supply reel 5L is pivotally connected to the support base 3L of the supply reel through the pin shaft 4L, and the pin shaft 4L is integrated with the support base 3L and connected coaxially with the supply reel 5L. Similarly, the take-up reel 5R is connected through the pin shaft 4R is rotatably fixed on the tape reel support base 3R, and the bolt shaft is integrated with the support base 3R and coaxially connected with the tape reel 5R. Supply reel 5L and take-up reel 5R are movably mounted in known manner on parallel guides 2L and 2R, respectively, and are movable between...

no. 2 approach - pic 5 to 8

[0068] In the foregoing embodiments, the pushing means of each of the supply reel 5L and the take-up reel 5R has been described as including the sliders 10L and 10R integrally connected with the respective pushing pieces 10a. However, in the second preferred embodiment of the present invention, the urging means of each of the supply reel 5L and the take-up reel 5R comprises a generally elongated plate-like urging piece which, in response to movement of the rod-like core, moves around Rotate along an axis parallel to the length direction of the elongated plate-shaped push piece. The push means used in the reel brake mechanism connected only to the supply reel 5L will be described in detail below.

[0069] The opposite ends of the elongated plate-like pushing means 10a used in the second embodiment of the present invention are bent perpendicularly to the main body of the pushing piece 10a. The slender plate-like push piece 10a is installed on the bottom case 1, and its opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com