Heating sheet for atomizer, atomizer and electronic cigarette

A heating film and atomizer technology, applied in the field of electronic cigarettes, can solve problems such as affecting the user's experience, low e-liquid reduction, bad inhalation taste, etc., and achieve smooth oil guiding, high e-liquid reduction, The effect of good atomization taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

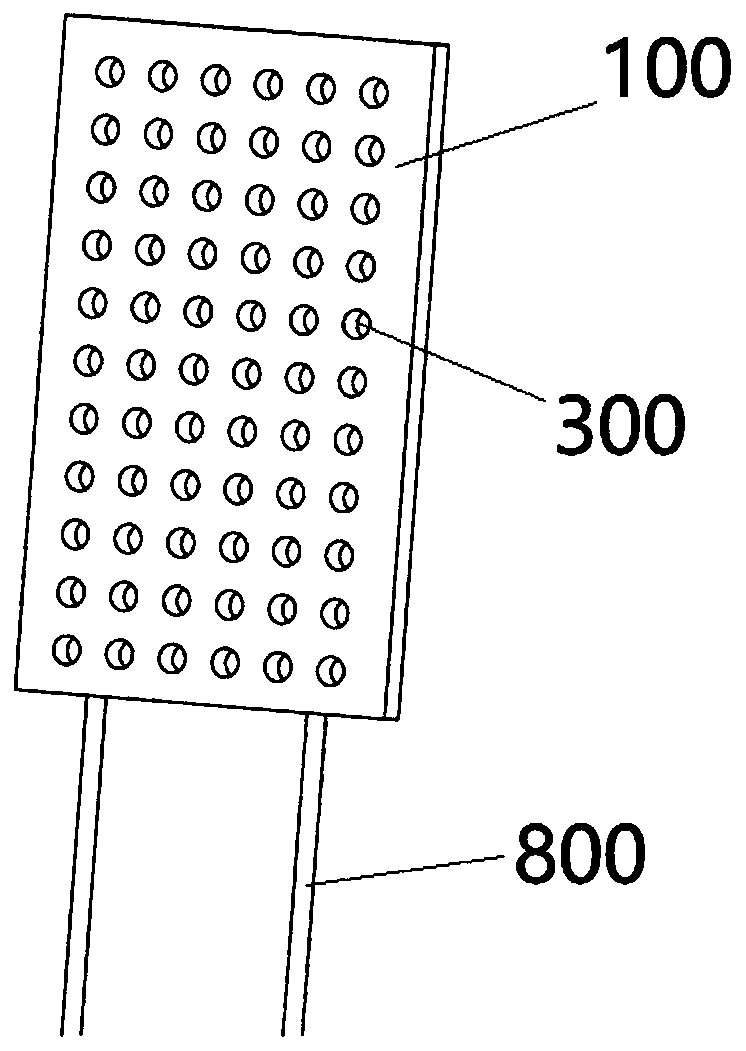

[0054] Such as figure 1 As shown, a heating chip for an atomizer includes a support member 100, the support member 100 is a ceramic sheet, and the support member 100 is provided with a number of through holes 300 in a uniform array, and the support member 100 is provided with There are heating components and lead-out electrodes 800, and the heating components are connected to the lead-out electrodes 800; in this embodiment, the heating components are printed resistors (not shown in the figure) formed after sintering the conductive paste printed by screen on the ceramic sheet .

Embodiment 2

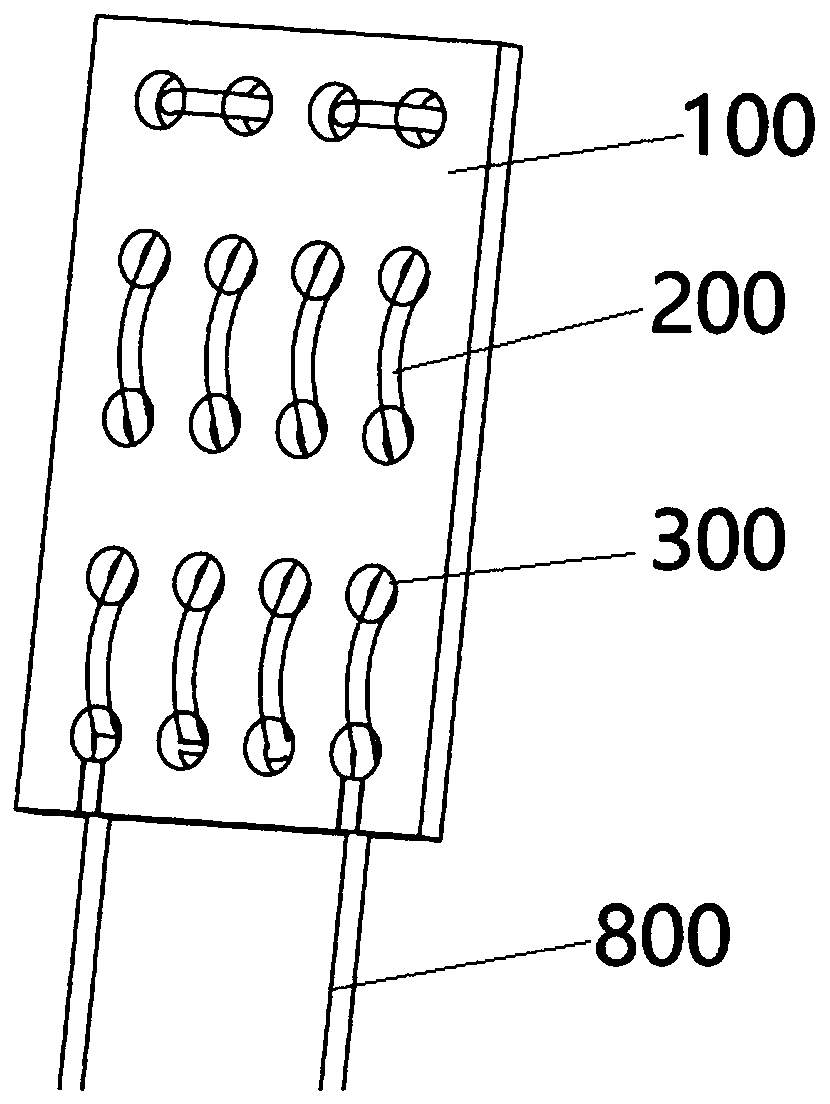

[0056] Such as figure 2 As shown, a heat generating sheet for an atomizer includes a support member 100, the support member 100 is a glass sheet or a ceramic sheet, and the support member 100 is provided with a number of through holes 300 in a uniform array, through which the heating wire 200 passes. By winding between the through holes 300 and close to the support member 100 , the two ends of the heating wire 200 can be used as the lead-out electrodes 800 , or the two ends of the heating wire 200 can be welded to the lead-out electrodes 800 .

[0057] The manufacturing method is to sinter the glass sheet or ceramic sheet with holes first, and then wind the heating wire 200 evenly between the holes so that it is close to the glass sheet or ceramic sheet.

Embodiment 3

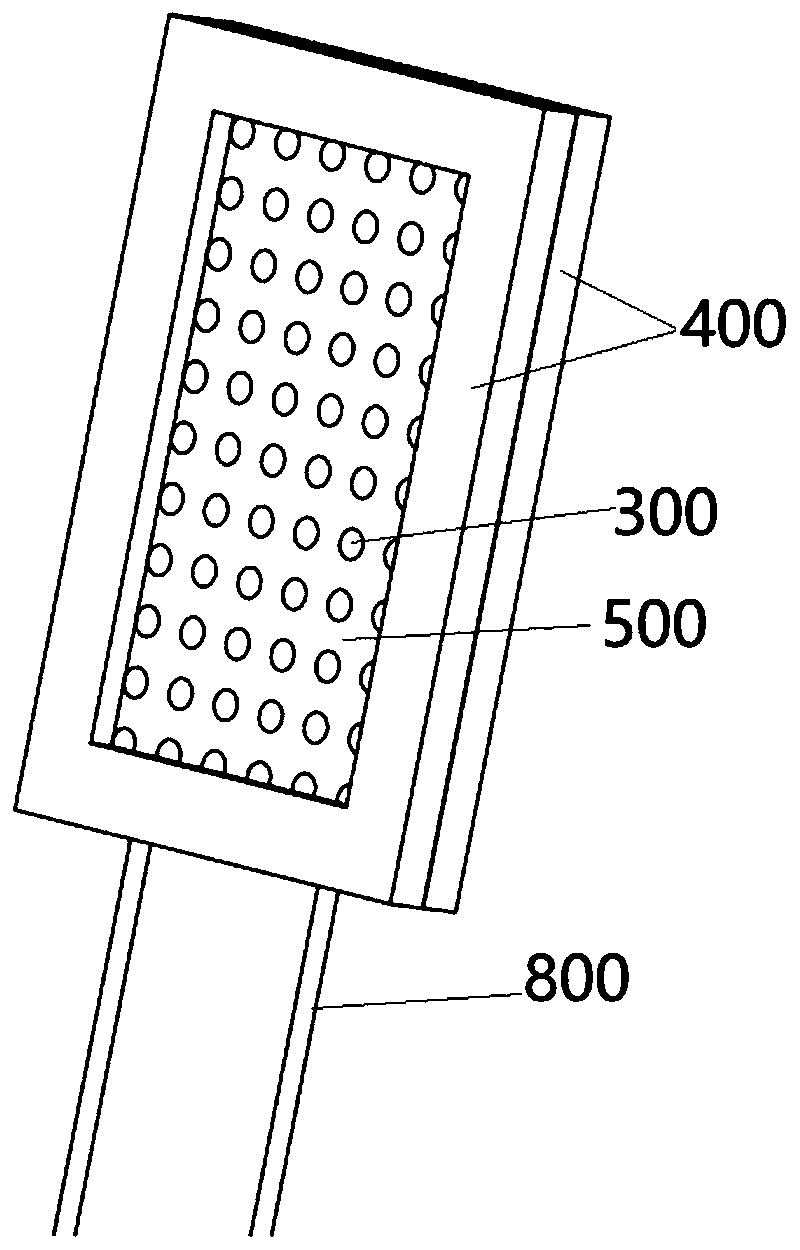

[0059] Such as image 3 As shown, a heating sheet for an atomizer includes an insulating frame 400 made of ceramic or glass, and the heating component is a metal heating sheet 500 provided with a plurality of through holes 300. 400, the two insulating frames 400 are docked to fix the metal heating sheet 500. Adopting this technical solution, a ceramic frame or a glass frame is made first, and the heating plate is etched out with a thin steel sheet to achieve desired resistance, and then the lead-out electrode 800 is butt-welded with the thin steel sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com