Modular centrifugal pendulum-type dynamic vibration absorber experiment table

A dynamic vibration absorber and centrifugal pendulum technology, which is applied in the testing of instruments, engines, and testing of machine/structural components, etc., can solve the problems of reducing torsional vibration of the drive train, intensifying speed fluctuations, and inability to limit the speed fluctuations. The effect of convenient installation, small footprint, and easy transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to better understand the present invention, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

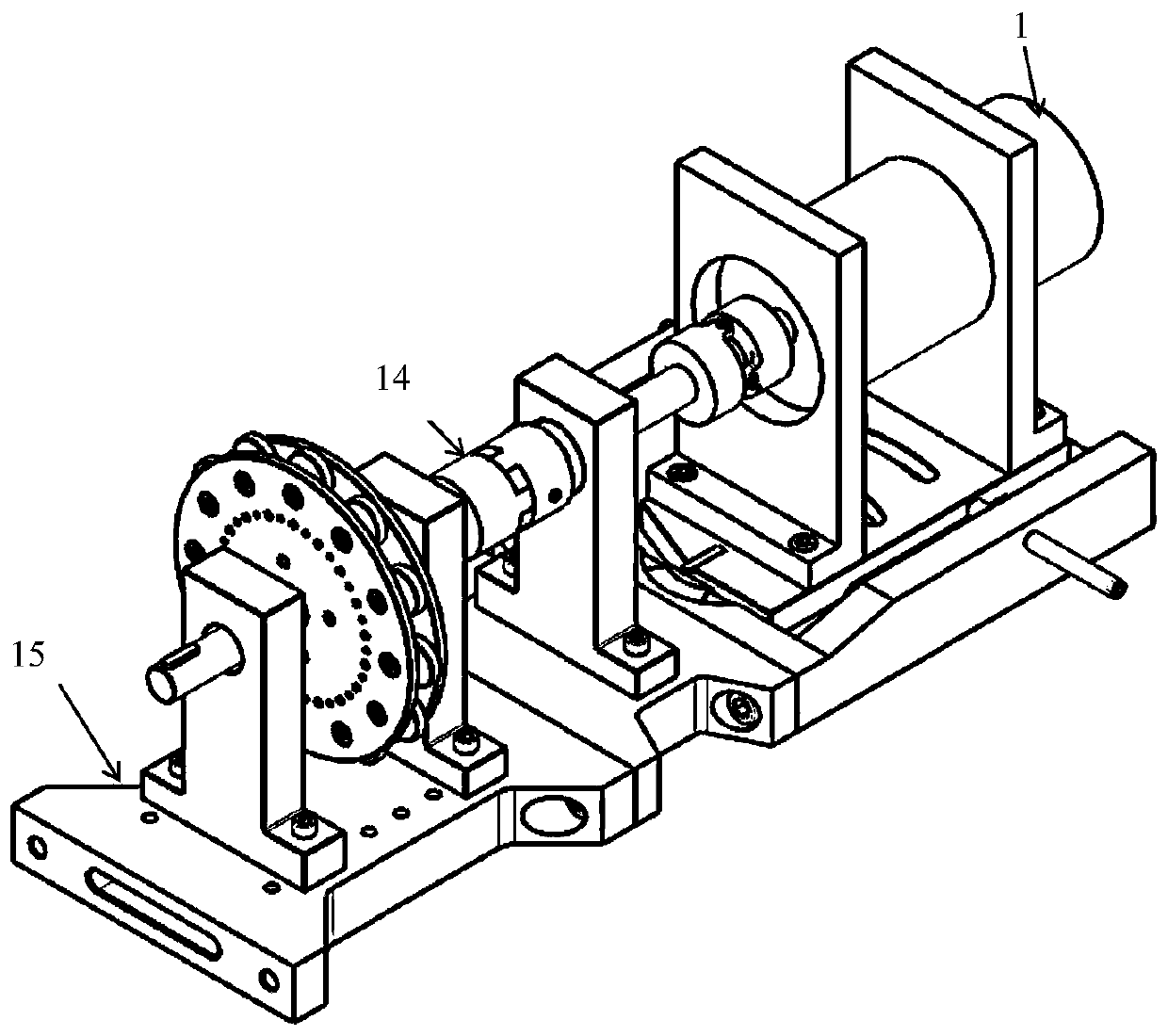

[0052] like Figure 1 to Figure 6 As shown, a modular centrifugal pendulum dynamic vibration absorber test bench includes sequentially connected excitation sources, transfer modules and at least one free combination module,

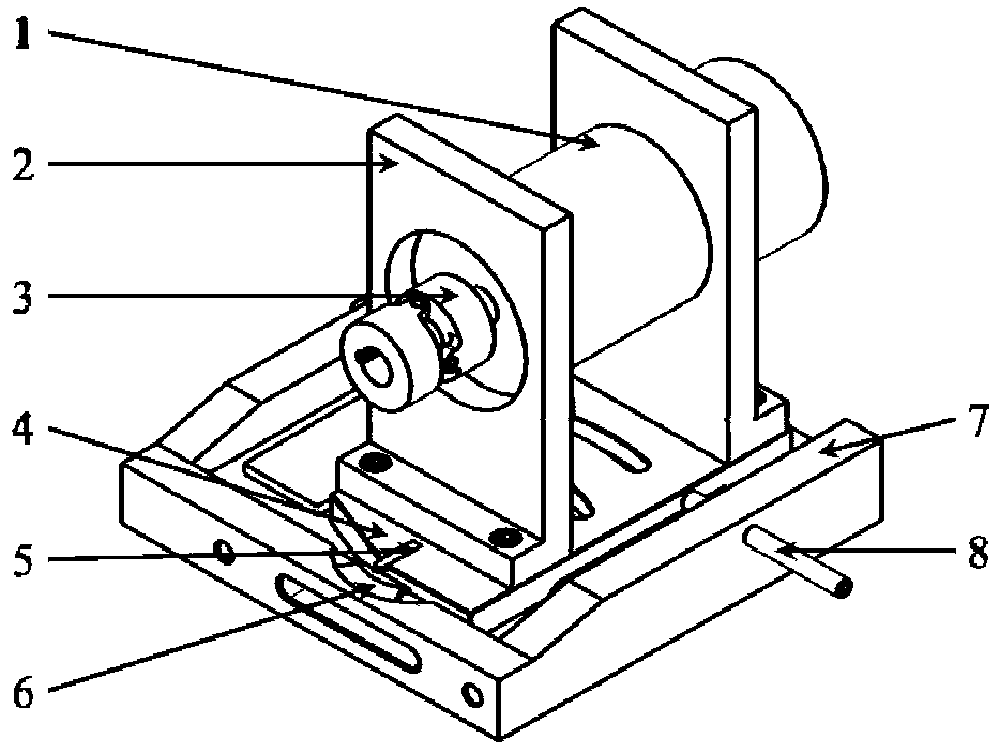

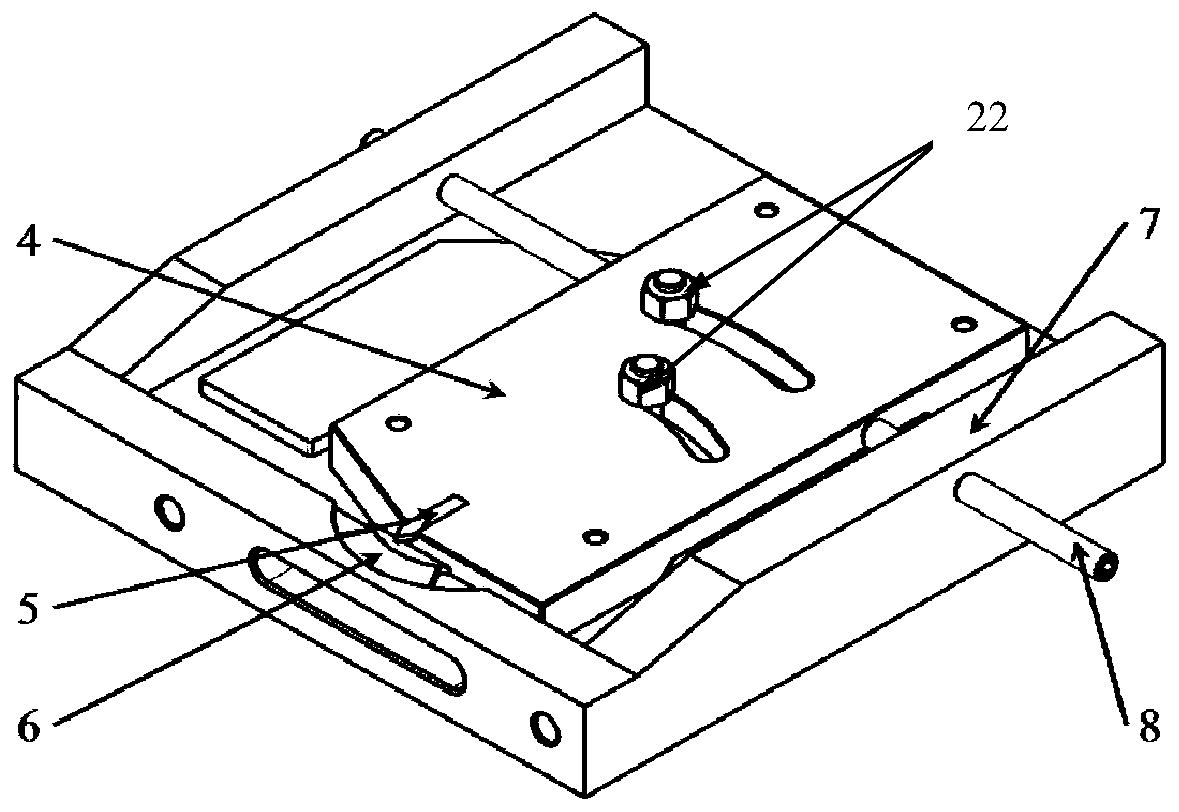

[0053] The incentives mentioned include:

[0054] Excitation source base 7;

[0055] The rotating seat 4 is movable and arranged on the base 7 of the excitation source with an adjustable angle, and

[0056] The motor 1 is fixedly arranged on the rotating base 4 through the motor bracket 2;

[0057] like Figure 5 As shown, the adapter module includes:

[0058] Adapter seat 12;

[0059] The bracket 9 is fixed on the adapter seat 12 by bolts;

[0060] a sliding bearing 10, fixed on the upper end of the bracket 9; and

[0061] The adapter shaft 11 is slidingly mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com