Power station boiler membrane type water-cooled wall cleaning device

A membrane-type water-cooled wall and cleaning device technology, which is applied to the removal of solid residues, treatment of combustion products, and combustion methods, can solve problems such as small structural stress, large changes in boiler heat load, and difficult handling of the top of the boiler. The effect of clear image and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

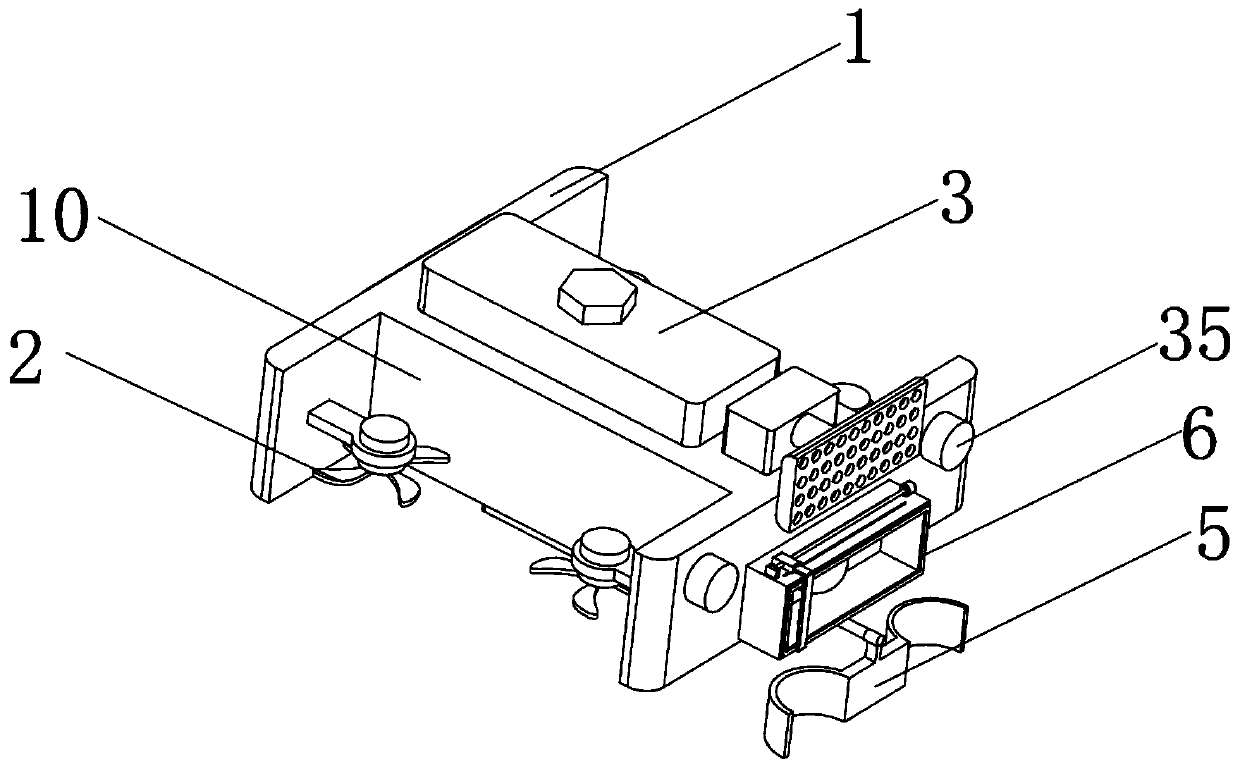

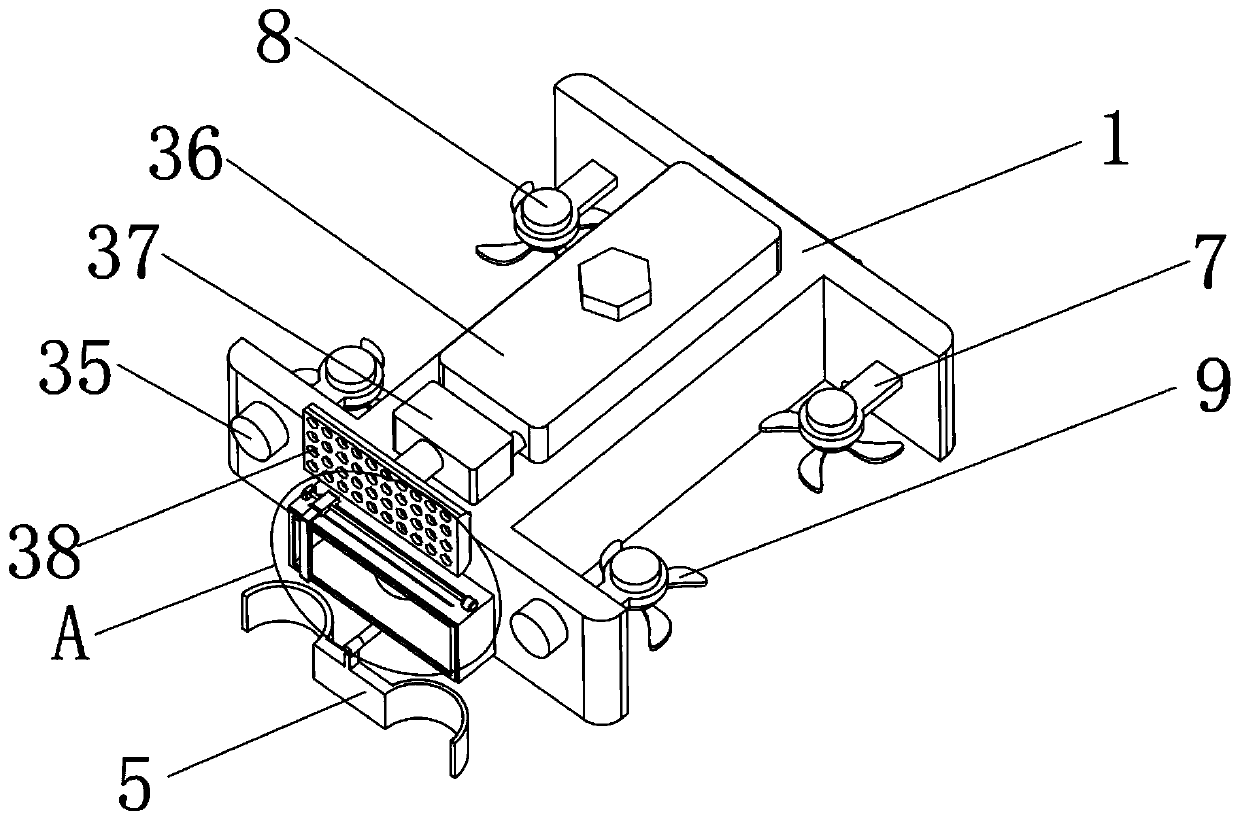

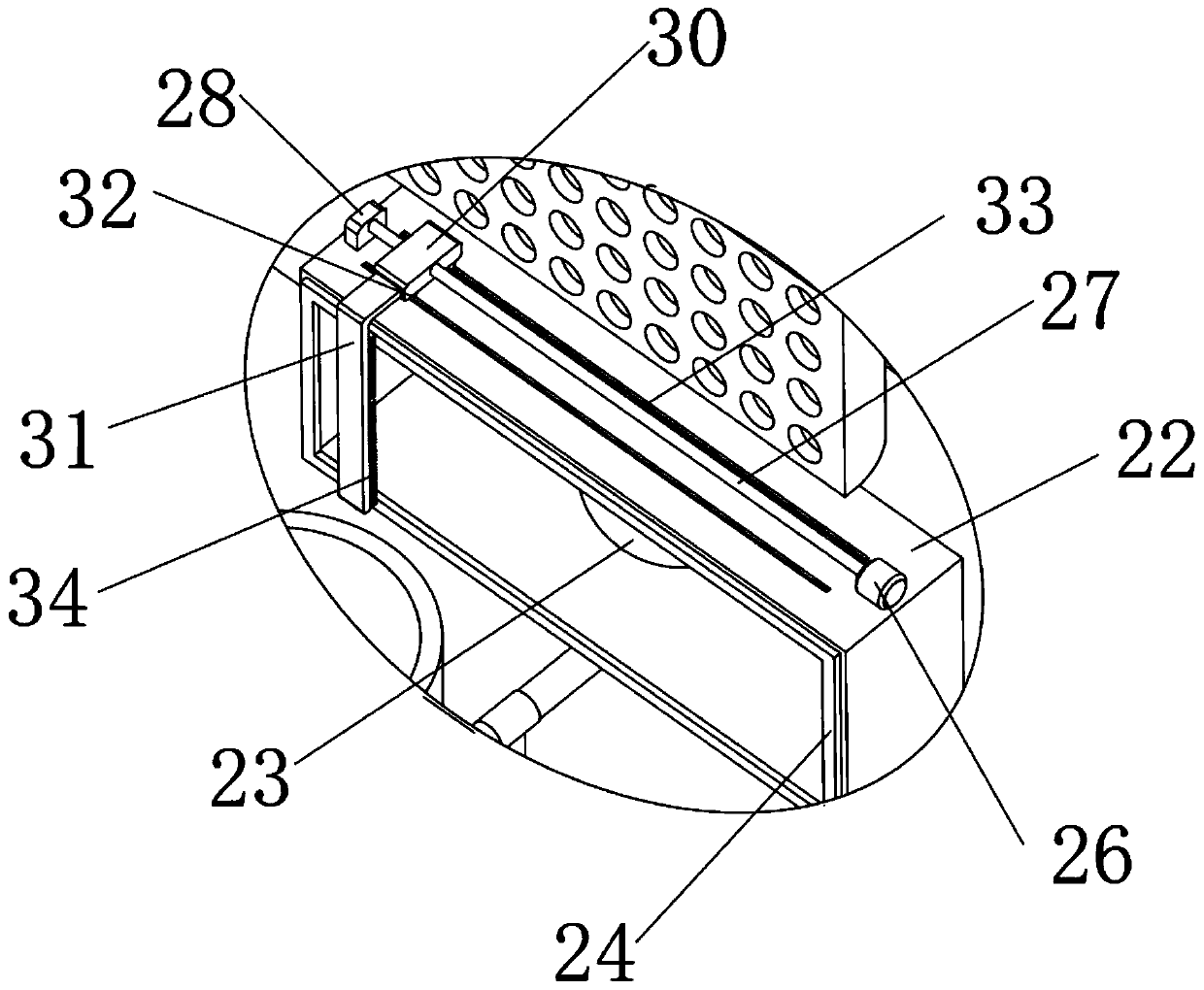

[0040] see Figure 1-12 , the present invention provides a technical solution: a power plant boiler membrane water wall cleaning device, including a housing 1, the two sides of the housing 1 are equipped with wing devices 2, and the top of the housing 1 is fixed with a sprinkler 3. The bottom of the housing 1 is provided with a drive device 4, the output end of the drive device 4 is movably connected to the ash removal mechanism 5, and the side of the housing 1 close to the ash removal mechanism 5 is fixed with a camera mechanism 6.

[0041] The wing device 2 includes a support frame 7, a first micro-motor 8 and a rotating blade 9, and a U-shaped through hole 10 is opened on both sides of the housing 1, and the support frame 7 is fixed on the U-shaped through hole 10 On the wall of the hole, the rotating vane 9 is fixed on the output end of the first micro motor 8 .

[0042] Working principle: The output end of the first micro-motor 8 drives the rotating blade 9 to rotate, w...

Embodiment 2

[0052] see Figure 13-16 Here, there is a difference from Embodiment 1. Since the cleaning part 21 is movably connected to the connecting rod 20, the cleaning part 21 can be disassembled from the connecting rod 20, and the connecting rod 20 moves away from the end of the fixed block 14. A welding device 47 is provided;

[0053] The welding device 47 includes a welding shell 48, a fixed plate 49, a heating wire 50 and a clamping device 51, the fixed plate 49 is fixed inside the re-welding shell 48, and the end of the connecting rod 20 away from the fixed block 14 is provided with a Circular groove 52, one end of the heating wire 50 is set in the circular groove 52, and the other end of the heating wire 50 passes through the fixed disk 49 and is connected to one end inside the welding shell 48, and the clamping device 51 is provided On the welding shell 48 and on the surface of the connecting rod 20 is provided a locking groove 53 , and the welding shell 48 is locked in the loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com