Pre-alignment device and testing equipment

A technology of positioning device and carrier, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of troublesome disassembly and replacement of movable limit blocks, many mechanical contacts of the carrier surface, and large damage to the carrier surface, etc. Detection accuracy and detection efficiency, improve pre-alignment accuracy and manual feeding efficiency, and ensure the effect of stable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

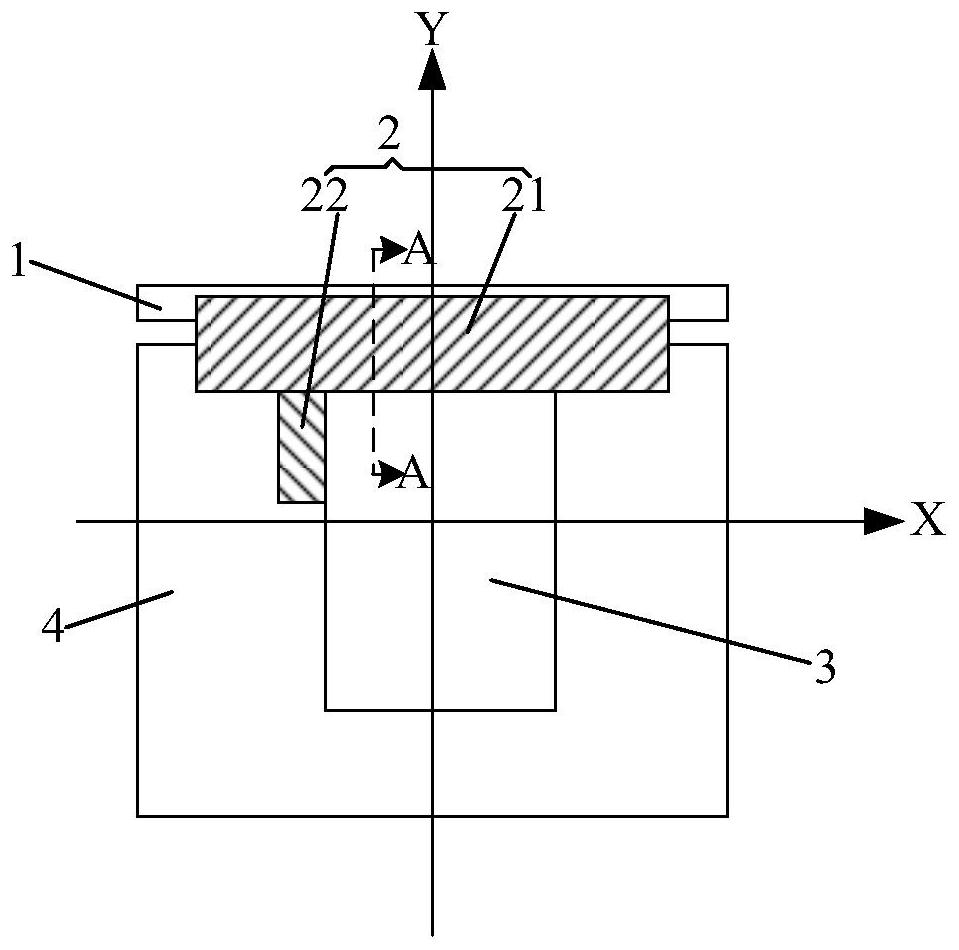

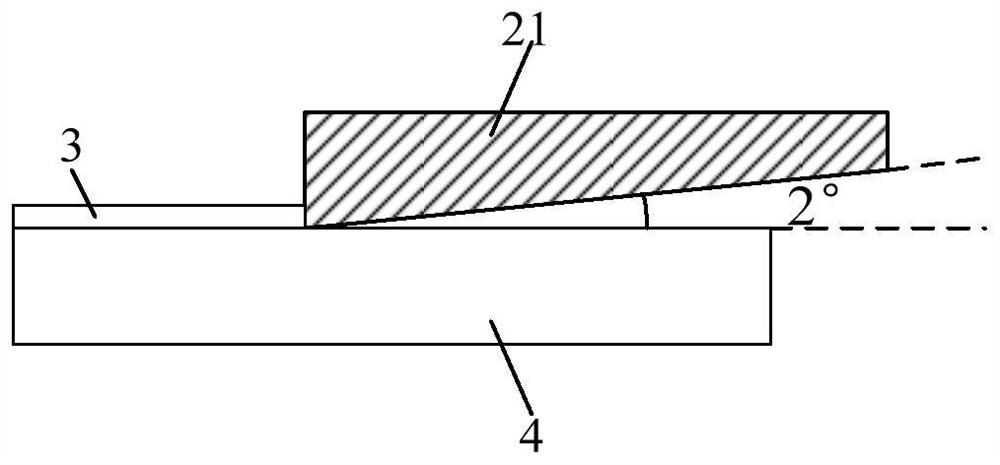

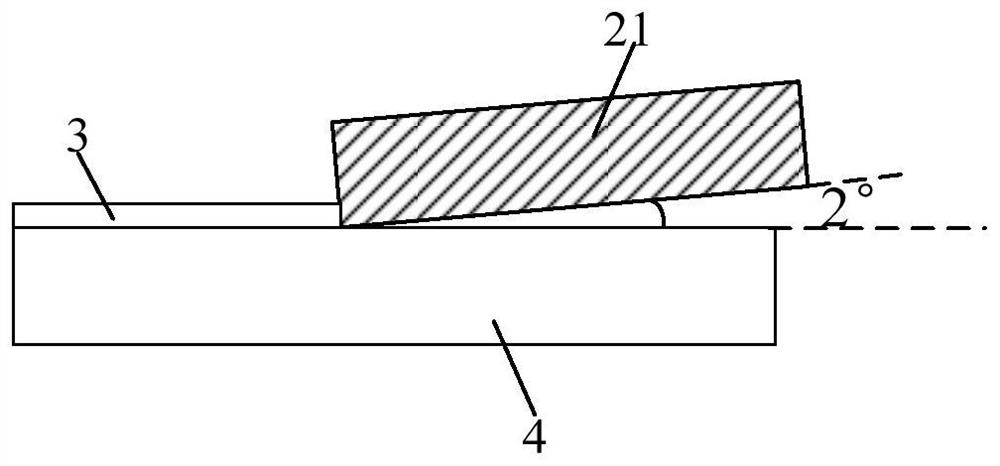

[0026]This embodiment provides a pre-alignment device, such asfigure 1 withfigure 2 As shown, it includes a fixed structure 1 and a pre-aligned structure 2. The pre-aligned structure 2 is movably connected to the fixed structure 1, and the pre-aligned structure 2 is located on the surface of the stage 4 carrying the substrate 3 to be tested in the pre-aligned state, The pre-alignment structure 2 includes a baffle 21 and a stop 22 that respectively define the position of the substrate to be tested in a first direction X and a second direction Y that are perpendicular to each other. In the pre-alignment state, the baffle 21 and the stop 22 It is in line contact with the table surface of the carrier 4, and the line contact part is located at the end of the baffle 21 and the stop 22 that is in contact with the substrate 3 to be tested.

[0027]By making the baffle 21 and the stopper 22 in the pre-aligned state to be in line contact with the surface of the stage 4, compared with the existin...

Embodiment 2

[0039]This embodiment provides a pre-alignment device. The difference from Embodiment 1 is that in this embodiment, in the pre-alignment state, only the baffle or only the stopper is in line contact with the surface of the stage, and the line contact part It is located at the end of the baffle or stop which is in contact with the substrate to be tested.

[0040]In this embodiment, the other structure of the pre-alignment device is the same as that in Embodiment 1, and will not be repeated here.

[0041]The beneficial effects of the embodiment 1-2: the pre-alignment device provided by the embodiment 1-2, by making the baffle and / or the stopper in the pre-alignment state come into line contact with the surface of the stage, compared with the existing Pre-alignment of the substrate to be tested by the contact between the movable limit block and the surface of the stage can relatively reduce or eliminate the gap between the baffle and the surface of the stage and the contact position of the s...

Embodiment 3

[0043]This embodiment provides a detection device used to perform lighting detection on a display substrate, including the pre-alignment device in Embodiment 1 or 2.

[0044]The detection equipment also includes a carrier, which is used for vacuum adsorption and fixation of the display substrate; the pre-alignment device is arranged on one side of the carrier. When performing lighting inspection on the display substrate, fix the pre-alignment device on the side of the stage, and then perform pre-alignment on the manually loaded display substrate. After the pre-alignment is completed, perform the display substrate lighting test.

[0045]By adopting the pre-alignment device in Embodiment 1 or 2, the detection equipment can improve its detection accuracy and detection efficiency, and can also ensure stable detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com