Prefabricated assembly production device and prefabricated assembly method of wooden structure mortise and tenon components

A technology of prefabricated assembly, production equipment, applied in the direction of manufacturing tools, woodworking utensils, processing machines for manufacturing flat surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

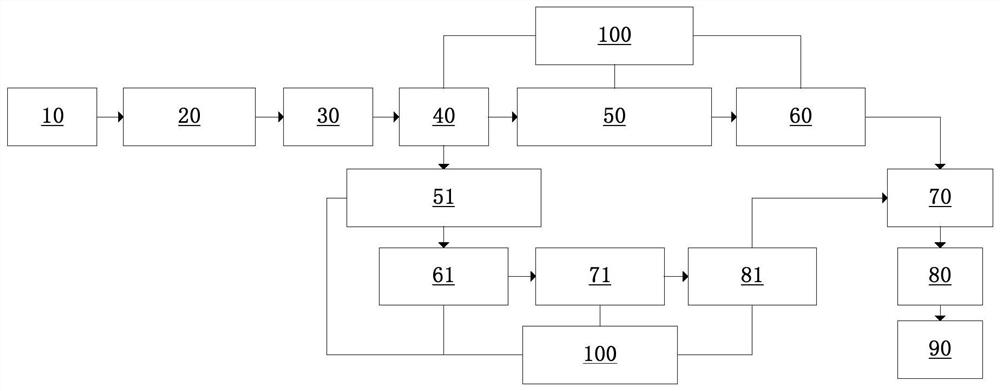

[0051] See figure 1 The structure of the prefabricated assembly production device for wooden structure mortise and tenon components in this embodiment is illustrated. This embodiment provides a prefabricated assembly production device for traditional wooden structure mortise and tenon components, which includes: a feeding machine 10, a log peeling machine 20, a drying kiln 30, a sorting machine 40, and a first fixed-length cross-cut sawing machine 50 , the second fixed-length cross-cut sawing machine 51, longitudinal cutting saw machine 61, four-sided planing and milling machine 71, square tenon opening machine 60, straight tenon tenon opening machine 81, combined press machine 70, sorting machine 80, packing machine 90 , transfer device (not shown in the figure) and waste recycling device 100; Wherein:

[0052] The output port of feeder 10 is connected with the input port of log peeling machine 20, the output port of log peeling machine 20 is connected with the input port of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com