Three-degree-of-freedom spherical wrist based on hydraulic direct drive without singular configuration

A degree of freedom and hydraulic technology, applied in the field of robotics, can solve problems such as poor dynamic response characteristics of joints, low load/self-weight ratio, high manufacturing/maintenance costs, etc., and achieve easy wrist posture control, high load/self-weight ratio, and kinematic characteristics simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

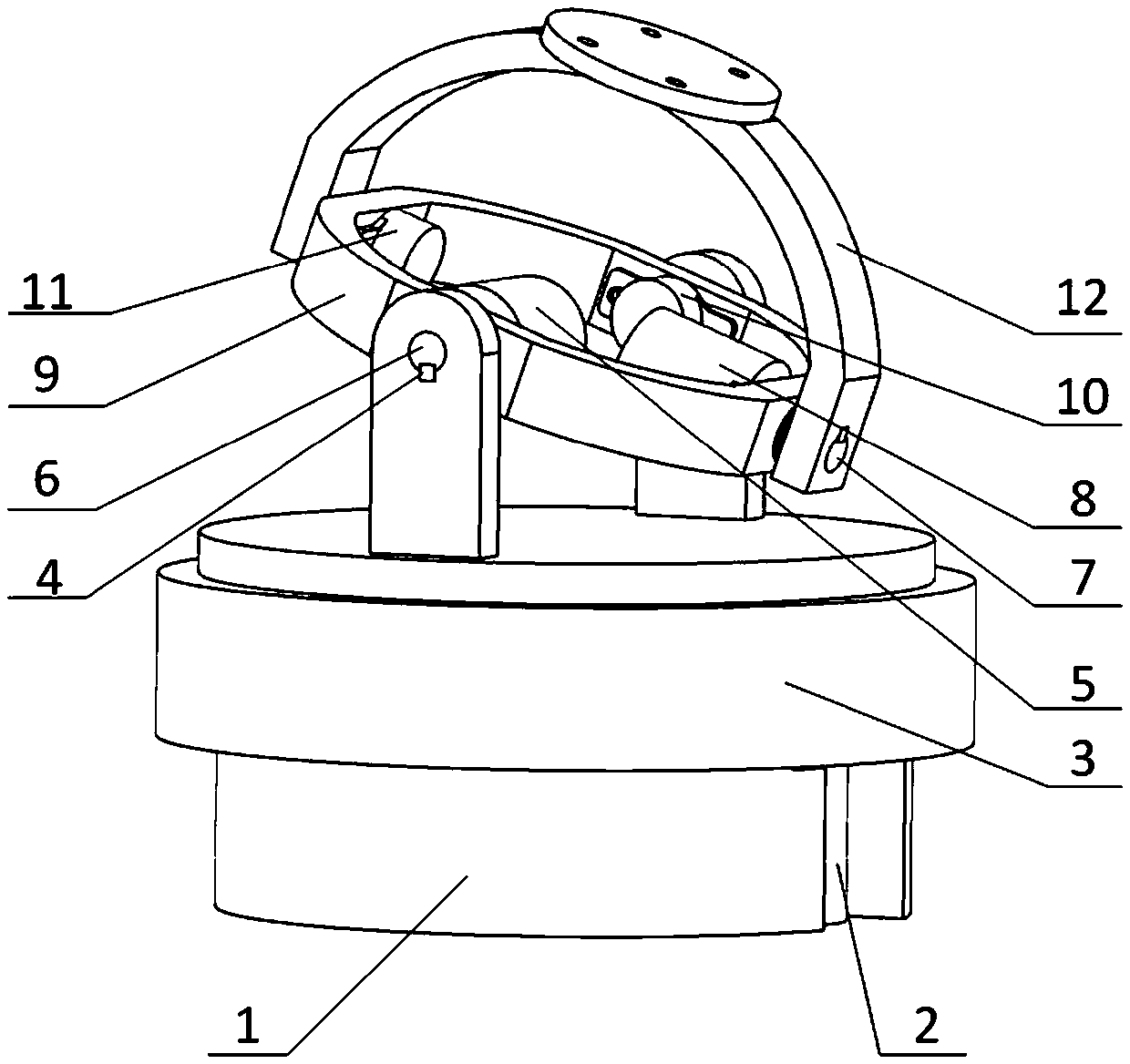

[0021] Specific implementation mode one: combine Figure 1-Figure 7 To describe the embodiment of the present invention in detail, a hydraulic direct-drive three-degree-of-freedom spherical wrist without a singular configuration in this embodiment includes a fixed block 1, a first-stage hydraulic motor 2, a rotating disc 3, a first-stage angle sensor 13, Rotating ring 9, second-stage hydraulic motor 5, second-stage angle sensor 10, third-stage hydraulic motor 8, third-stage angle sensor 11, and rotating semicircular ring 12.

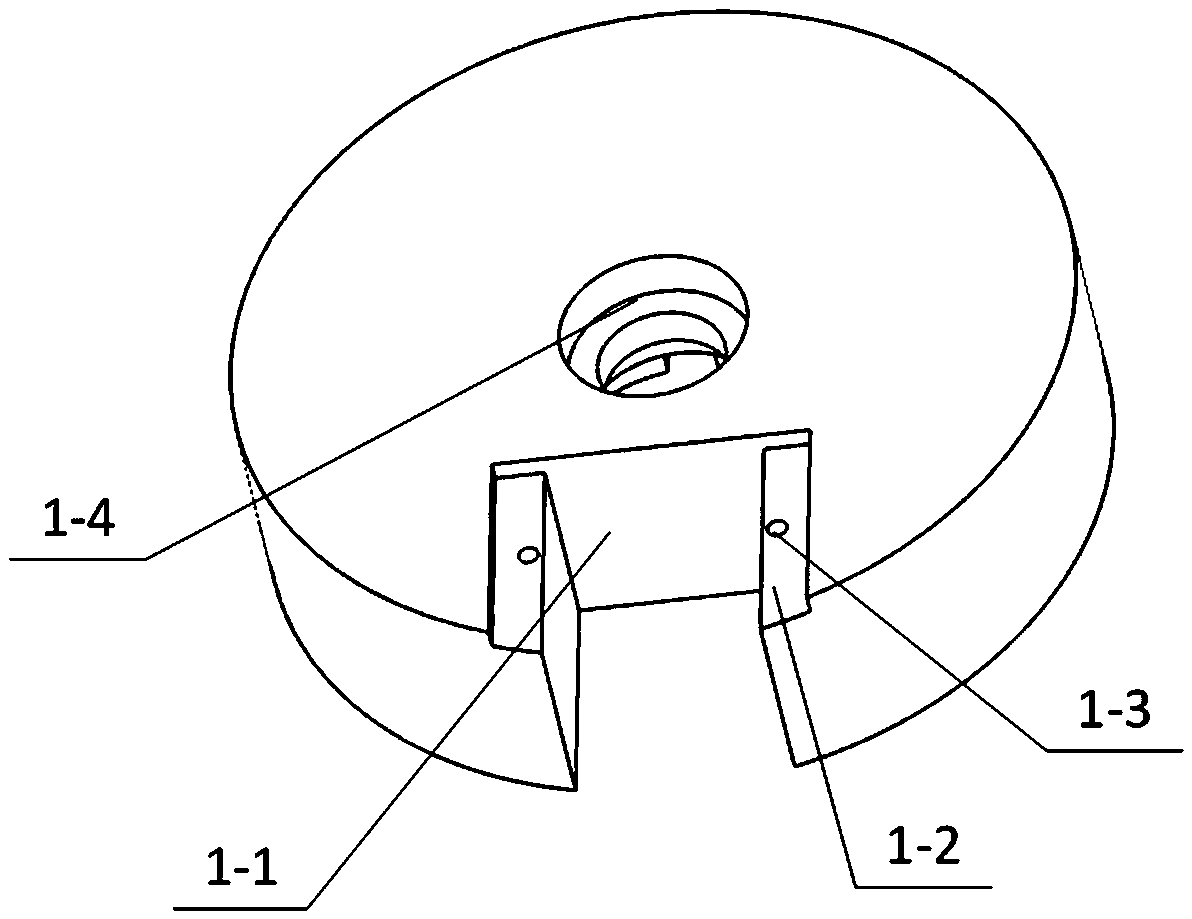

[0022] like image 3 , Figure 4 As shown, the fixed block 1 includes a hydraulic motor groove 1-1, a flange groove 1-2, a motor threaded hole 1-3, a fixed block bearing groove 1-4, a fixed threaded hole 1-5, and a wire groove 1-6 , the first stage hydraulic motor is placed in the hydraulic motor slot 1-1, the first stage hydraulic motor flange 15 is fixedly connected with the threaded hole 1-3 on the fixed block 1 through screws, and the first stage h...

specific Embodiment approach 2

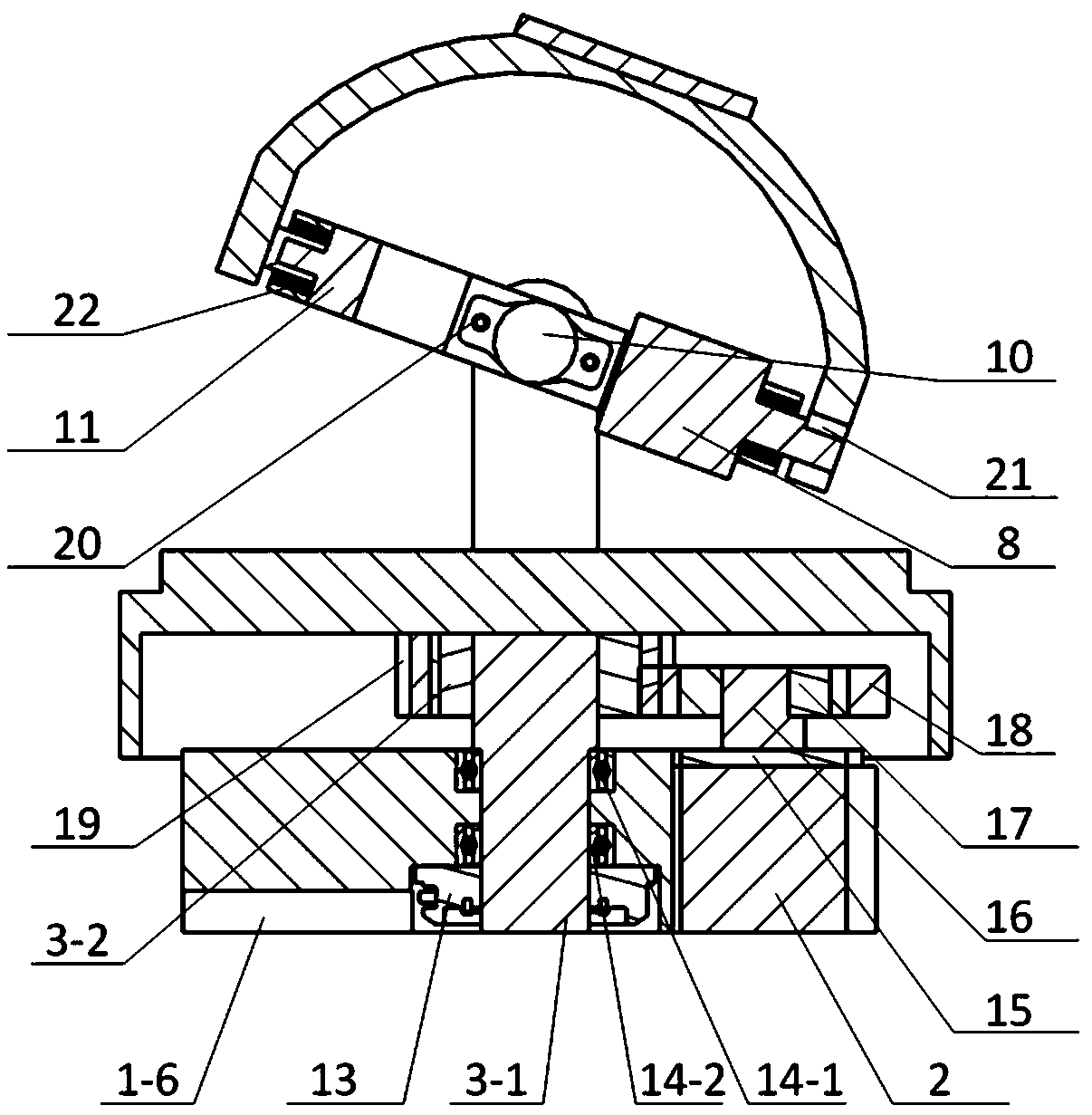

[0025] Specific implementation mode two: combination figure 2 Describe the embodiment of the present invention, a hydraulic direct-drive three-degree-of-freedom spherical wrist without singular configuration in this embodiment has a vertical through hole in the middle of the fixed block 1, and the fixed block bearing grooves 1-4 are arranged in the middle of the fixed block 1. In the through hole, an upper bearing 14-1 and a lower bearing 14-2 are arranged in the fixed block bearing groove 1-4, and the rotating shaft 3-1 is rotationally connected with the fixed block 1 through the upper bearing 14-1 and the lower bearing 14-2, and the rotating shaft 3 The shaft shoulder of -1 pushes on the inner ring of the upper bearing 14-1, and the lower end of the rotating shaft 3-1 is connected with the first-level angle sensor 13, and the first-level angle sensor 13 is also fixedly connected with the fixed block 1 by screws.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination figure 1 and figure 2 Describe the embodiment of the present invention. In the hydraulic direct drive three-degree-of-freedom spherical wrist of this embodiment, the second-stage hydraulic motor shaft 6 is connected with the first fixed key 4 and the first shaft hole 3-6. The rod 3-4 is fixedly connected, the second-stage hydraulic motor shaft 6 and the rotating ring 9 are rotationally connected through bearings, the shaft of the second-stage angle sensor 10 is inserted into the first shaft 3-5 to form a fixed connection, and the first shaft 3-5 It is rotatably connected with the rotating annulus 9 through a bearing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com