Installation tool for a hidden fastener and installation method for a fastener

A technology for installing tools and fasteners, applied in the direction of threaded fasteners, manufacturing tools, motor tools, etc., can solve problems such as damage to the grasping part, and achieve the effect of simple structure and mechanically stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

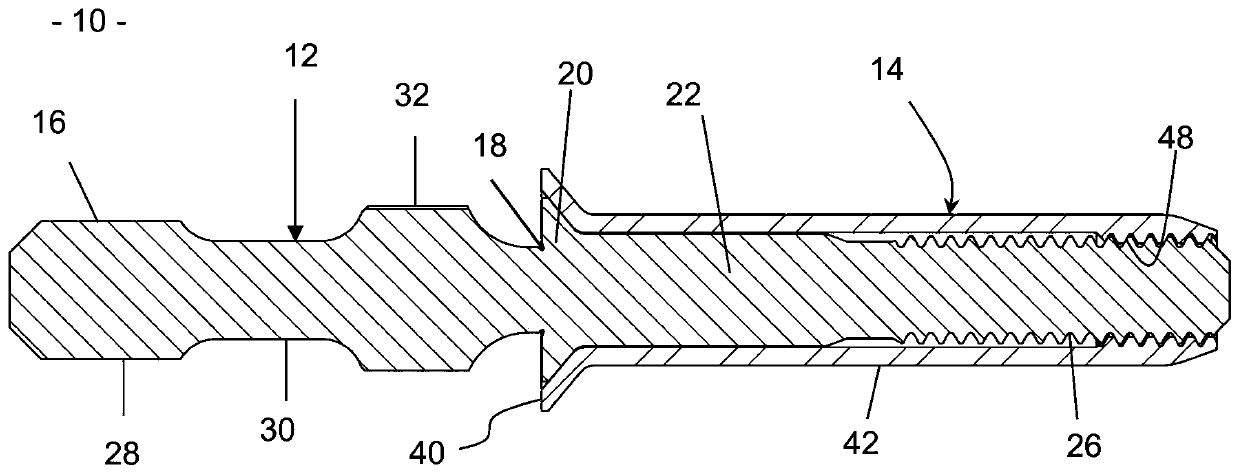

[0040] in the attached figure 1 Among them, the "pull screw" type fastener 10 applied in the present invention includes a screw 12 and a sleeve 14 . The screw 12 includes a grip 16 that can be broken during installation of the fastener, a breakout groove 18 , a milling head 20 , a post 22 and a threaded end 26 . The gripping portion 16 includes a cylindrical first gripping portion 28 , a blocking portion 30 and a second gripping portion 32 with grooves distributed on its outer surface.

[0041] The sleeve 14 includes an enlarged collar 40 for receiving the countersink 20 of the screw, and a tubular shaft 42 including a sleeve shaft 48 disposed at the end of the sleeve 14 opposite the collar 40 . The threading of the screw 12 and the threading of the threaded sleeve 14 are complementary. The tubular shaft 42 includes a deformable area (not shown in the figure), whose stiffness is lower than that of other parts, capable of forming a spherical protrusion under the action of tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com