Liquid crystal display element and liquid crystal composition

A technology of liquid crystal display elements and liquid crystal compositions, applied in liquid crystal materials, optics, instruments, etc., to achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

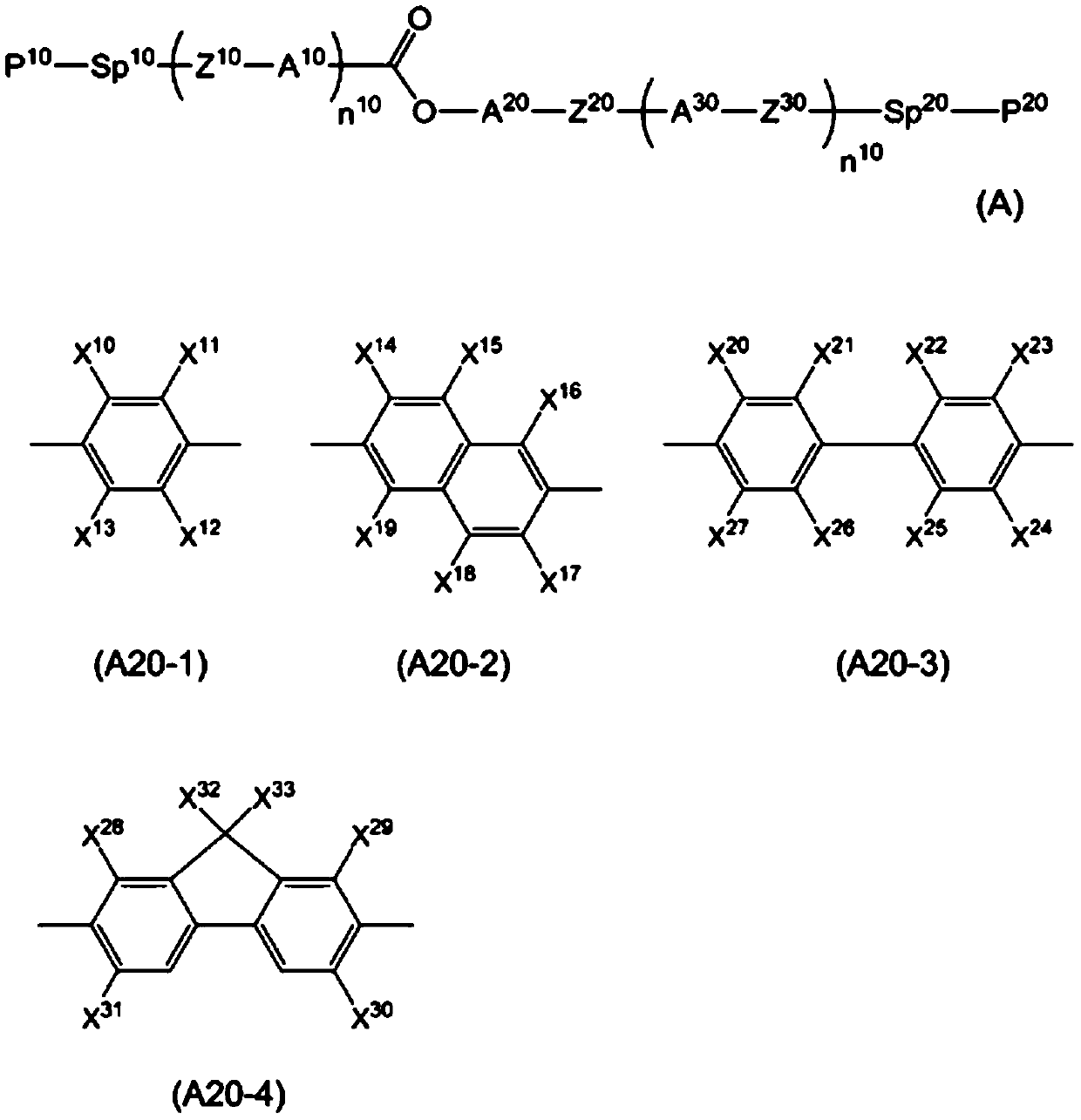

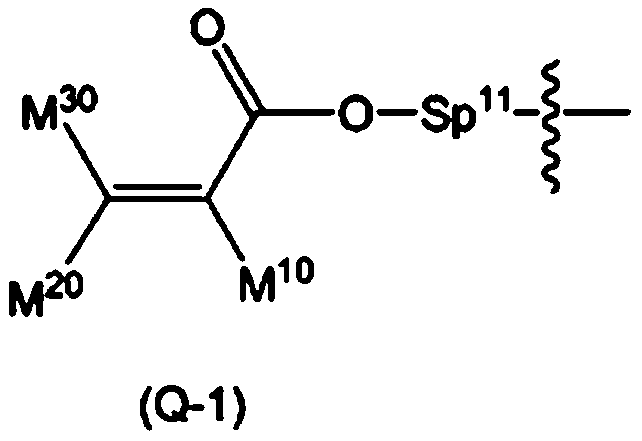

Method used

Image

Examples

Embodiment 1

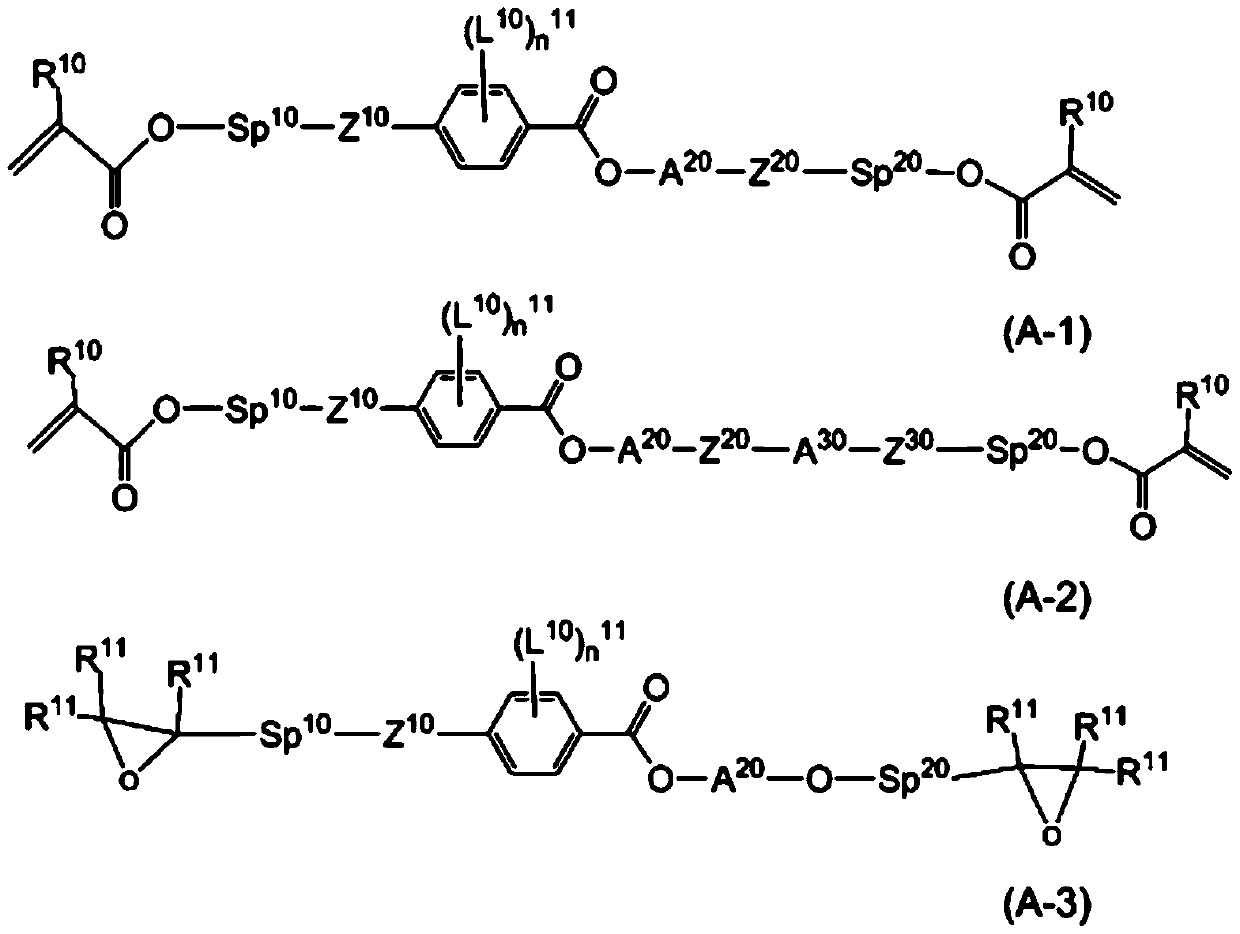

[0343] In the composition (M1), the compound (A-1-1-1) as the first additive is added at a ratio of 0.5 parts by weight, and the compound (5) with t=7 as an antioxidant is added at a ratio of 150 ppm . The mixture was injected into an IPS element having no alignment film at 90° C. (above the upper limit temperature of the nematic phase). While heating the IPS element at 90°C (above the upper limit temperature), irradiate the element with linearly polarized ultraviolet rays (313nm, 2.0J / cm 2 ), so as to obtain an element formed with an orientation control layer. The irradiated ultraviolet light becomes linearly polarized light by passing through the polarizer. Next, the device in which the orientation control layer was formed was placed on a polarizing microscope, and the orientation state of the liquid crystal was observed. The polarizer and the analyzer of the polarizing microscope are arranged such that their respective transmission axes are perpendicular to each other. ...

Embodiment 2~ Embodiment 29

[0345]As shown in the following Table 4, using the compositions (M1) to (M25), compound (5) of t=7 was added as an antioxidant at a ratio of 150 ppm, and the additives were mixed as shown in the following table. The temperature at the time of irradiating linearly polarized ultraviolet rays was set as shown in the following table. The presence or absence of light leakage was observed by the same method as in Example 1. As a result, no light leakage was observed, so the orientation was good. In addition, the following compound (RM-1) to compound (RM-3) were used as a 2nd additive.

[0346]

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com