Bionic liquid absorption core with cobweb structure and soaking plate using same

A technology of liquid-absorbing wicks and spider webs, which is applied in the construction of electrical equipment components, cooling/ventilation/heating transformation, electrical components, etc., can solve problems such as non-existence, and achieve the effect of rapid diffusion and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

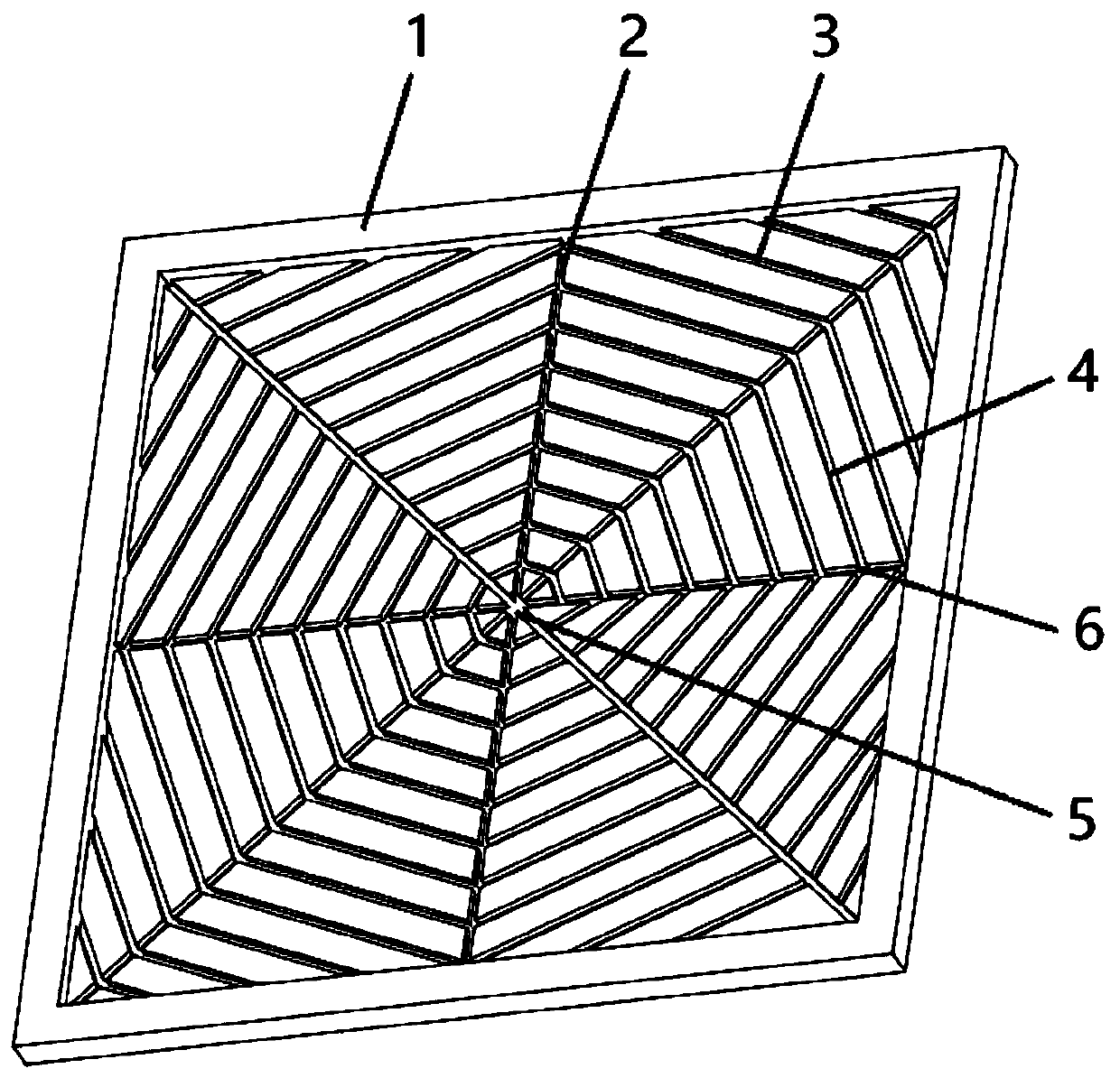

[0027] The utility model relates to a bionic liquid-absorbing core with a spider web structure, which is a groove structure formed along a spider web-shaped path on the inner side wall of an evaporation plate base. Boss areas are arranged around the evaporating plate for welding with the condensing plate to form a closed cavity.

[0028] The cobweb-shaped path is concave, and the concave part forms a groove structure.

[0029] The cobweb-shaped path includes a ring-shaped auxiliary path and multiple main paths; multiple main paths converge at the center of the evaporating plate and diverge to the surroundings of the evaporating plate, and the annular auxiliary path diverges from the middle of the evaporating plate in a spiral circle, and is connected with each main path. The paths intersect multiple times, so that the main path and the ring-shaped auxiliary path form a spider web; multiple main paths converge at the central point, and the main path and the ring-shaped auxiliar...

Embodiment 2

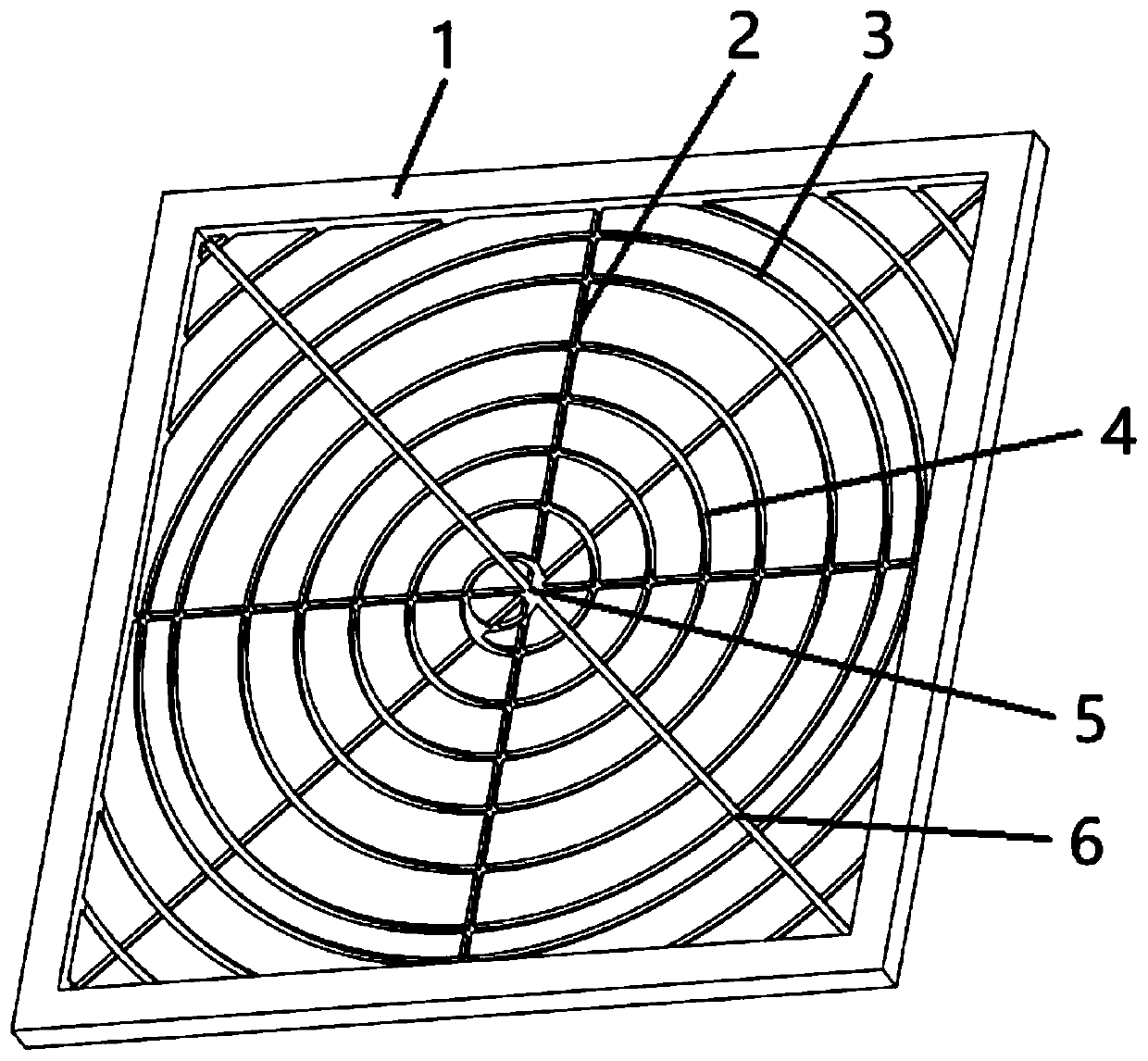

[0032] In this embodiment, along the helical divergence direction of the circular secondary path, the circular secondary path segments between adjacent nodes are arc-shaped, and the arc-shaped transitions between adjacent circular secondary path segments are smooth.

[0033] The parts not mentioned in this embodiment are the same as those in Embodiment 1.

[0034] The depth of the grooves is 0.4mm and the width of the spider web path is 0.5mm.

Embodiment 3

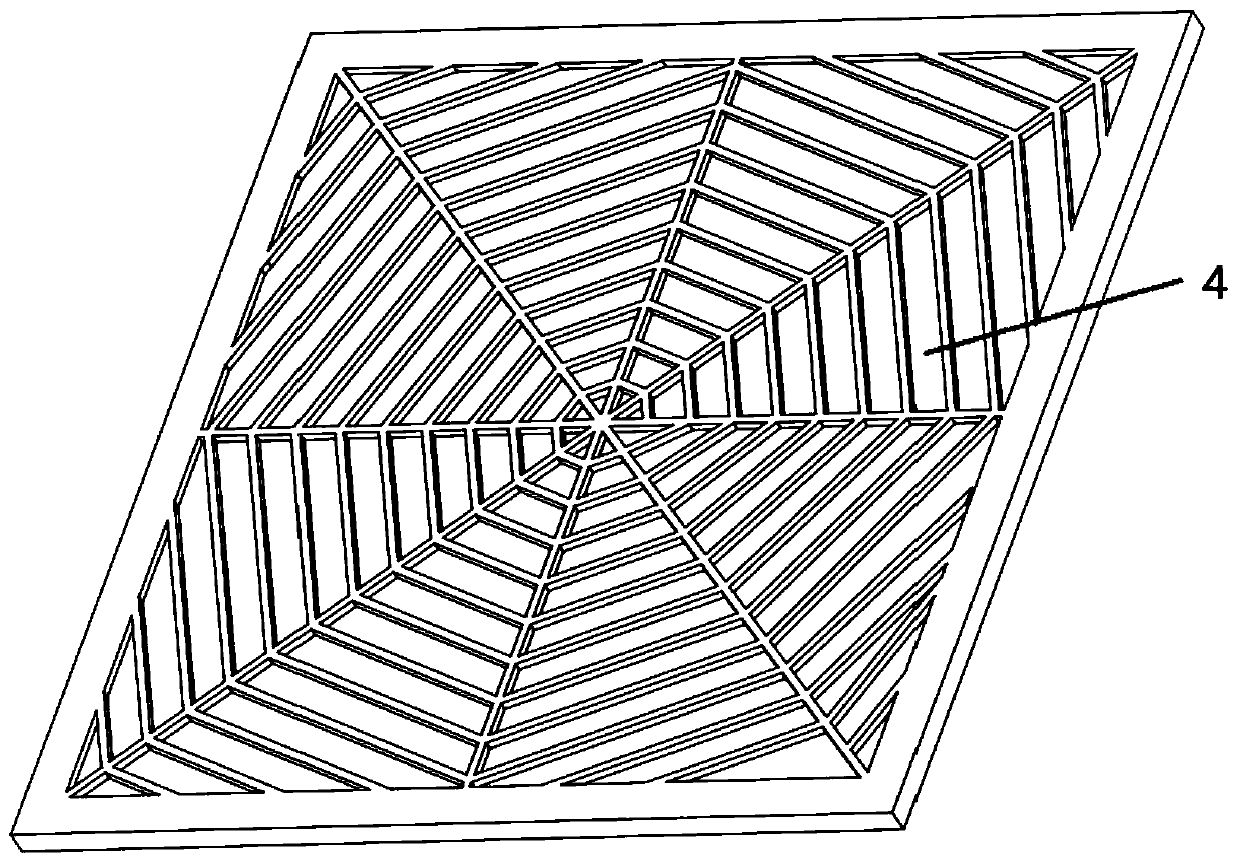

[0036] In this embodiment, the cobweb-shaped path is convex, and a groove structure is formed between the convex parts.

[0037] The absorbent core adopts sintered powder porous structure.

[0038] The parts not mentioned in this embodiment are the same as those in Embodiment 1.

[0039] The depth of the grooves is 0.3 mm and the width of the spider web path is 0.6 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com