Slide rail and equipment cabinet

A sliding rail and rail technology, which is applied in the server field, can solve the problems of long time consumption, cumbersome operation process, low sliding rail installation efficiency, etc., and achieve the effect of fixing and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

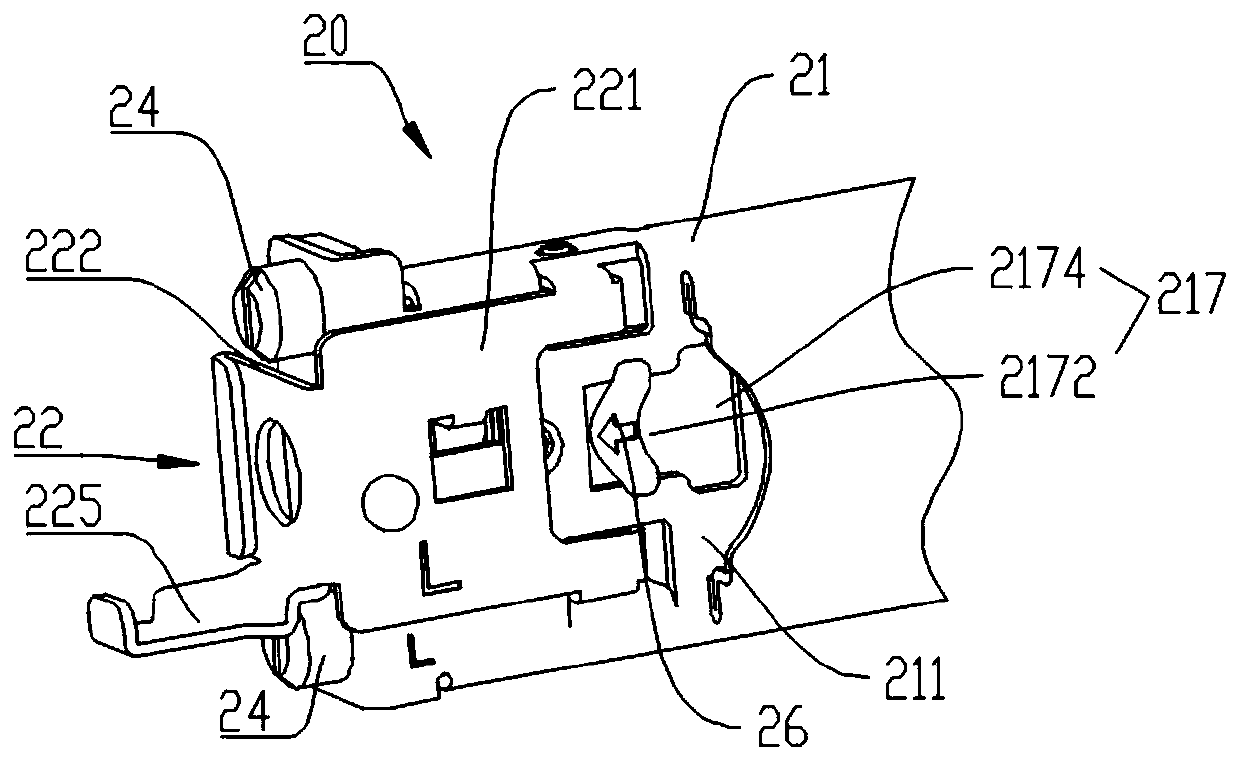

[0053] The technical solution of the slide rail and the cabinet provided by the present application will be described below with reference to the drawings in the embodiments of the present application.

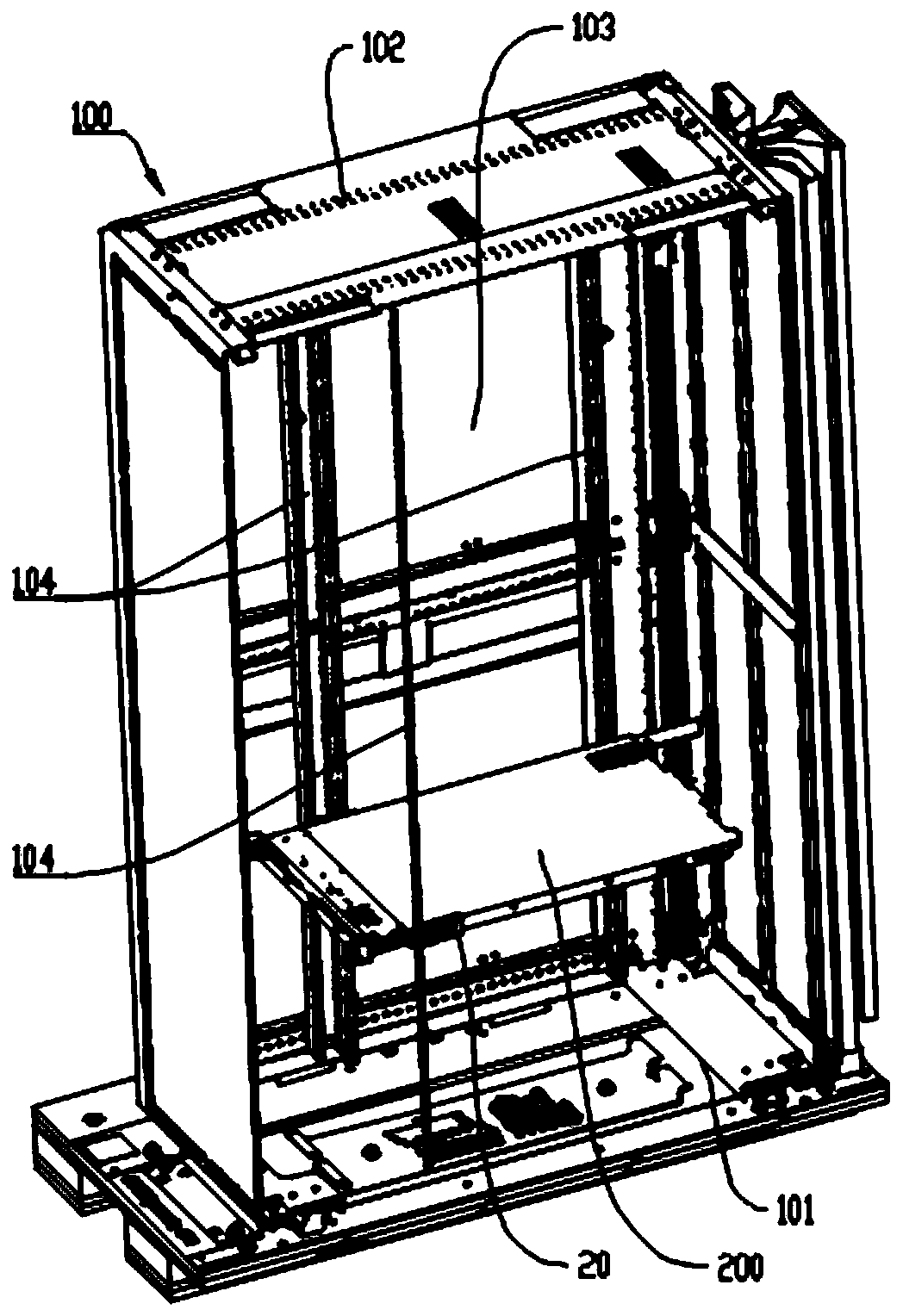

[0054] Such as figure 1 As shown, the cabinet 100 involved in the present application includes a base 101 and a top 102 which are arranged oppositely. The column 104 is vertically arranged on the side panel 103 of the cabinet 100 perpendicular to the horizontal direction. For example, if figure 1 As shown, four columns 104 perpendicular to the horizontal direction are set in the cabinet 100, and the horizontal distance between the two columns 103 on the same side plate 103 is the same as the horizontal distance between the two columns 103 on the other side plate 103 parallel to the side plate 103. The distance is the same.

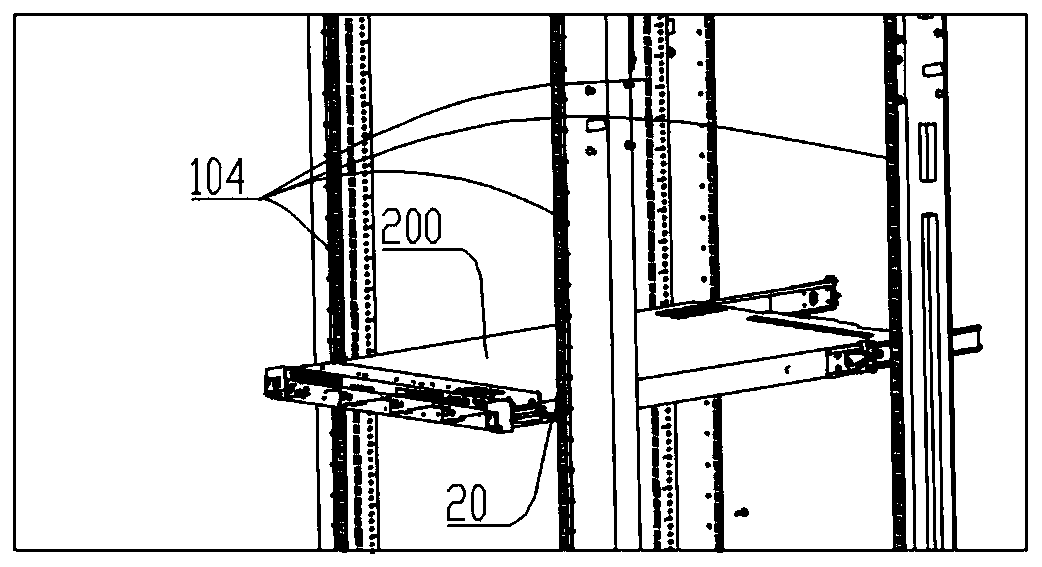

[0055] The slide rails 20 are arranged in pairs in the cabinet 100, wherein the front-end column 104 and the rear-end column 104 on the inside of one s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com