Loader drive axle extreme small sample reliability evaluation method based on BP neural network

A BP neural network, loader technology, applied in neural learning methods, biological neural network models, instruments, etc., can solve problems such as inapplicability to very small samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

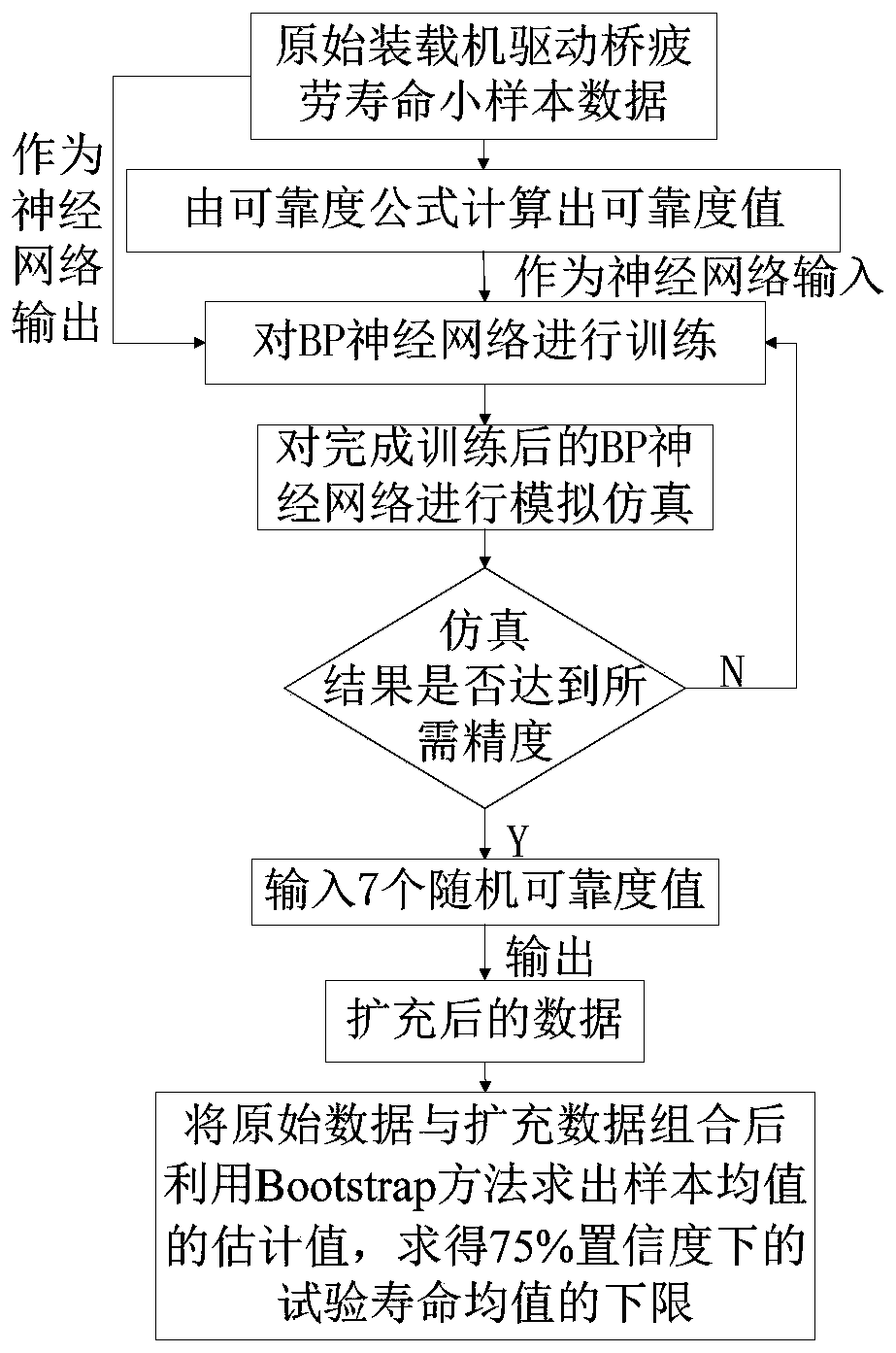

[0086] A method for evaluating the reliability of a loader drive axle provided by the invention operates on a Matlab platform and comprises the following steps:

[0087] Step 1, measure the fatigue life experimental data of n loader drive axle samples respectively by test, obtain n experimental data;

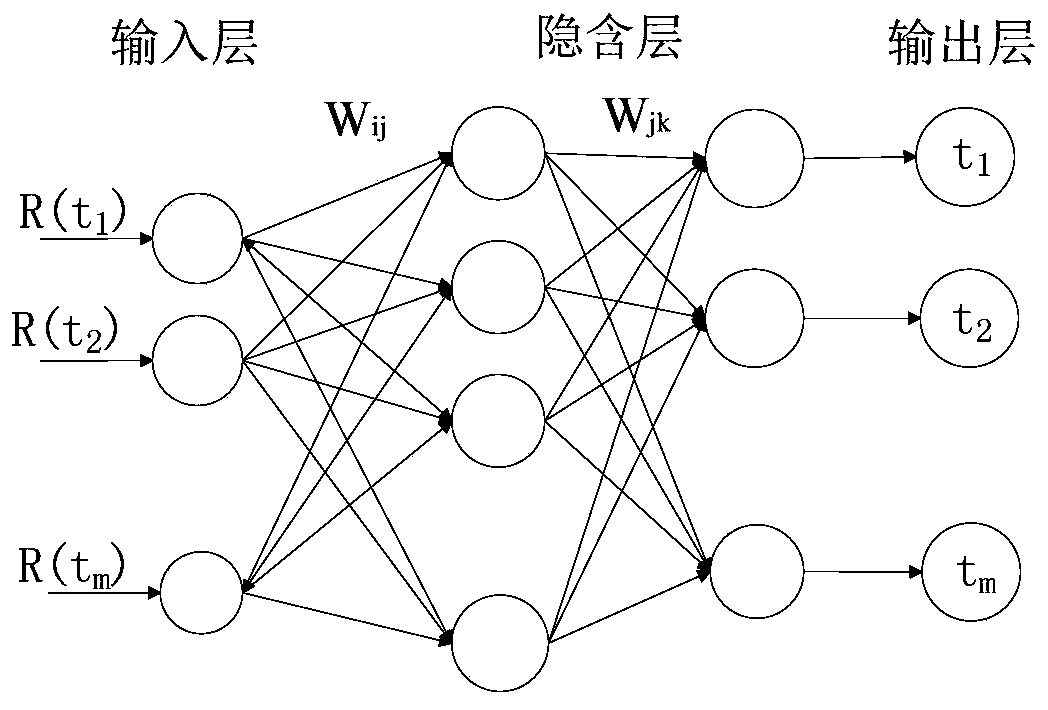

[0088] Step 2, establish the BP neural network model by the n test data obtained in step 1:

[0089] S1, according to the n fatigue life test data values obtained in step 1 to form the original sequence t 1 ,t 2 ,...t n , and use the reliability formula (1) to calculate the reliability R(t 1 ),R(t 2 ),...R(t n ), the resulting reliability R(t 1 ),R(t 2 ),...R(t n ) as input for training BP neural network:

[0090]

[0091] Among them, u Y is the average life of the loader drive axle fatigue test sample; σ is the standard deviation of the loader drive axle sample, and its value is σ=0.17;

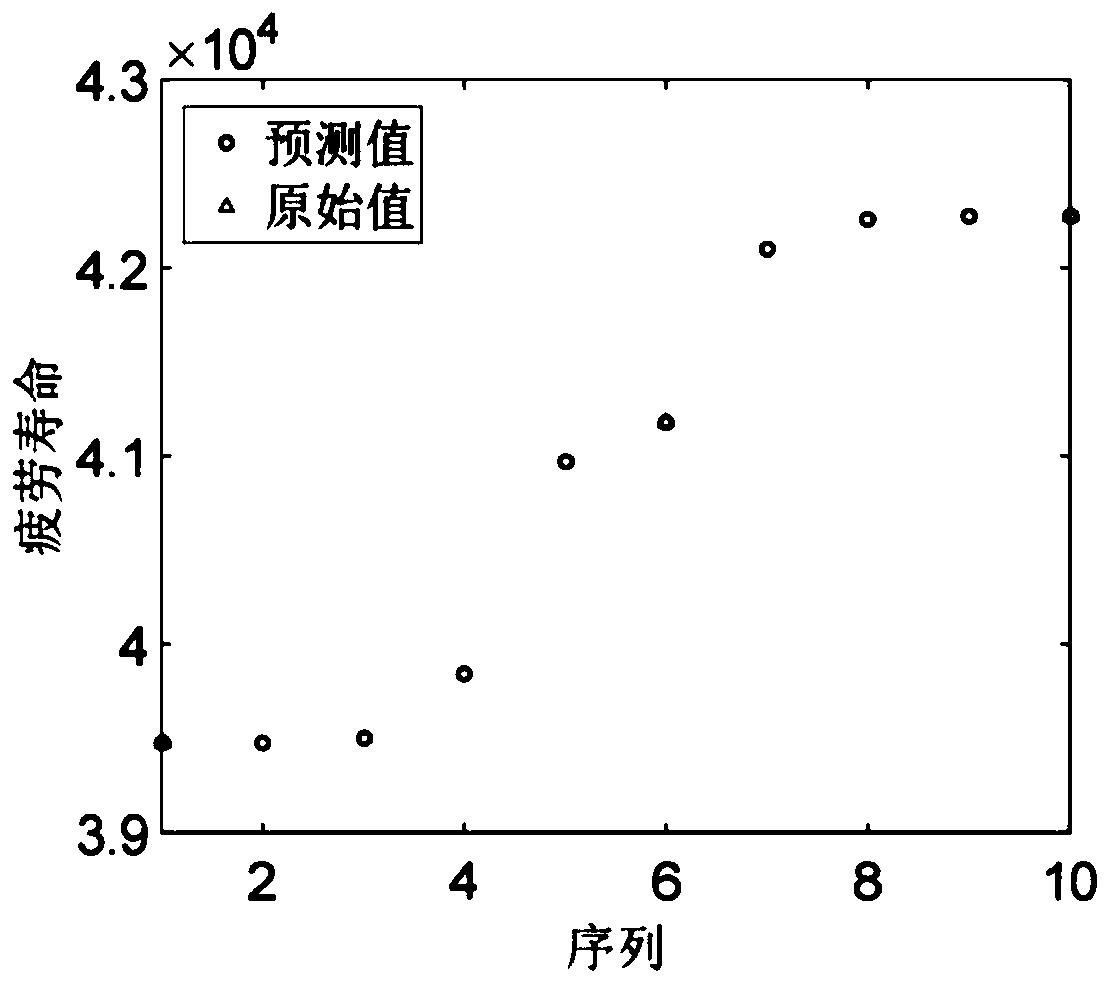

[0092] S2, make n fatigue life test data values into the original sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com