Small reactor main pump

A technology of pump shaft and pump casing, applied in the field of small reactor main pump, can solve the problems of high maintenance cost, large water consumption, complicated maintenance, etc., and achieve the effect of prolonging the service life and reducing the heat conduction area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

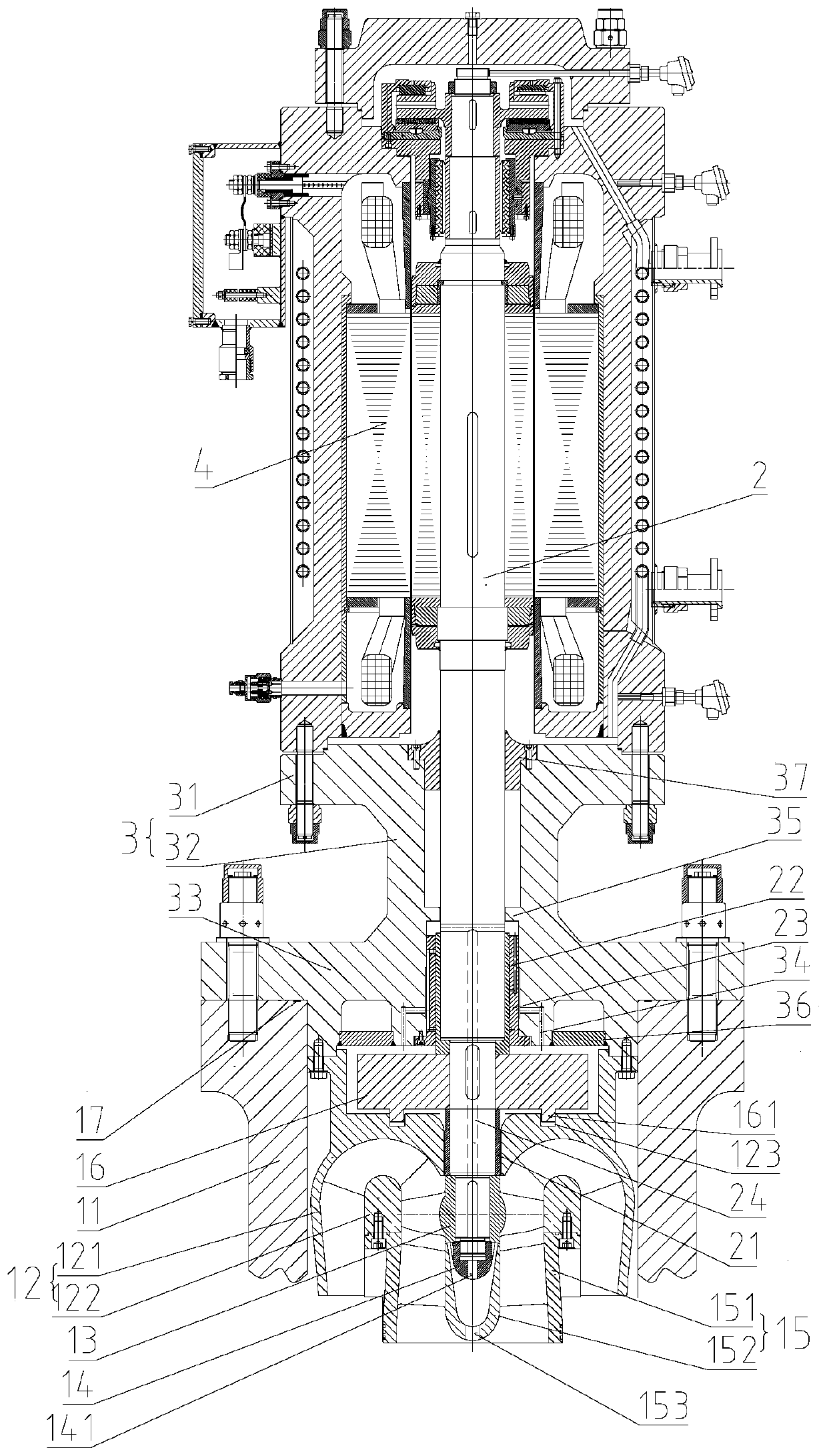

[0025] see figure 1 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

[0026] A small stack main pump of the present invention includes a pump end, a motor end, an air heat shield 3 between the pump end and the motor end, and a pump shaft 2 vertically penetrating the motor end and the pump end from top to bottom.

[0027] The pump end includes a pump casing 11 , a guide body 12 , an impeller 13 , an impeller nut 14 , guide vanes 15 , a balance disc 16 , and a main seal 17 .

[0028] The motor end includes a shielded motor 4 .

[0029] The air heat shield 3 comprises an upper flange 31 , a constriction 32 and a lower flange 33 . The bottom surface of the lower flange 33 is coaxially fixed on the top surface of the pump casing 11 , the bottom surface of the lower flange 33 and the top surface of the pump ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com