Self-adaption electronic speed governing method for PID diesel engine

A diesel engine and electronic speed regulation technology, which is applied in engine control, machine/engine, governor, etc., can solve problems such as integral saturation, restricting system dynamic and static performance, and difficult to adjust parameters online in real time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be specifically described below with reference to the accompanying drawings and specific embodiments.

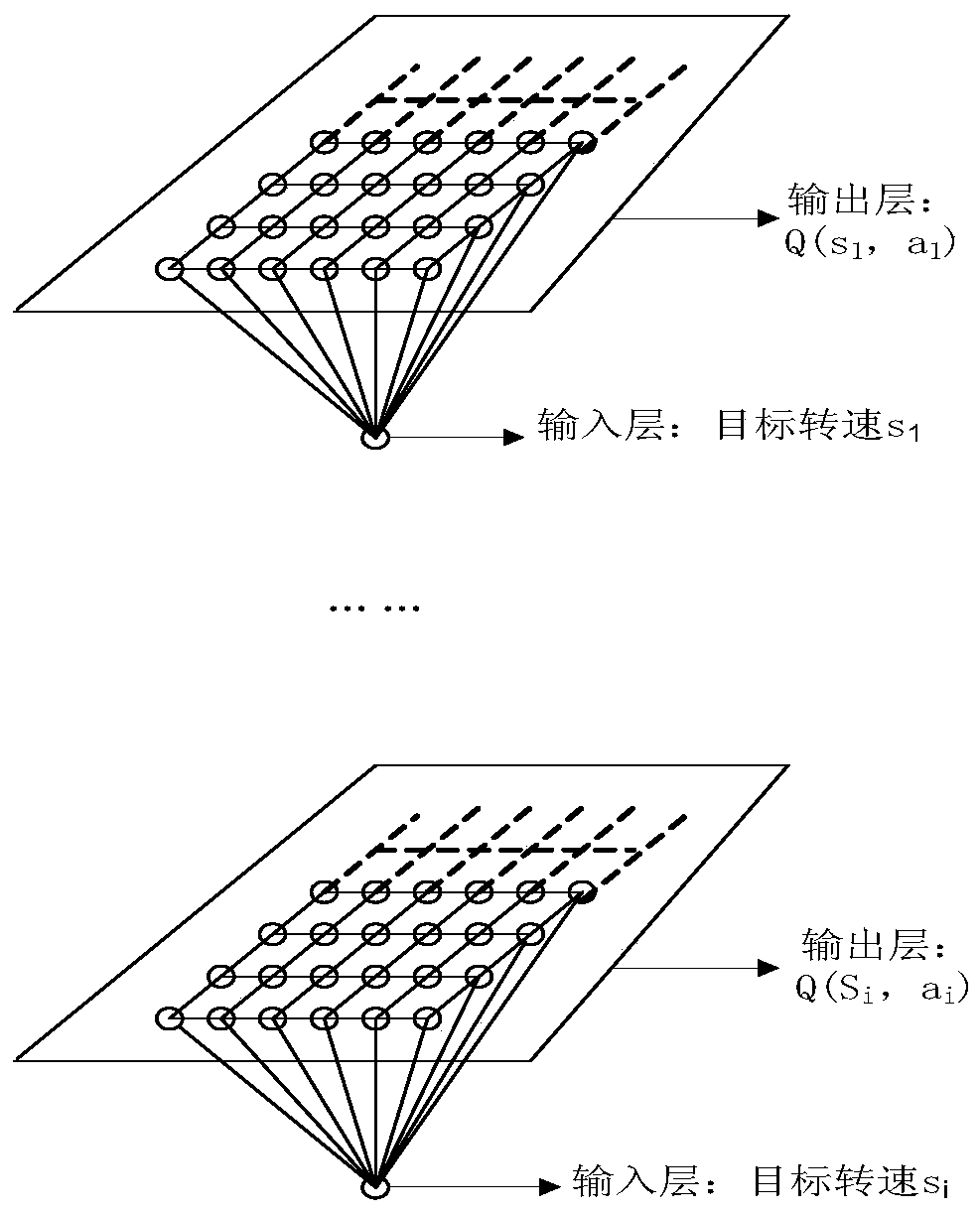

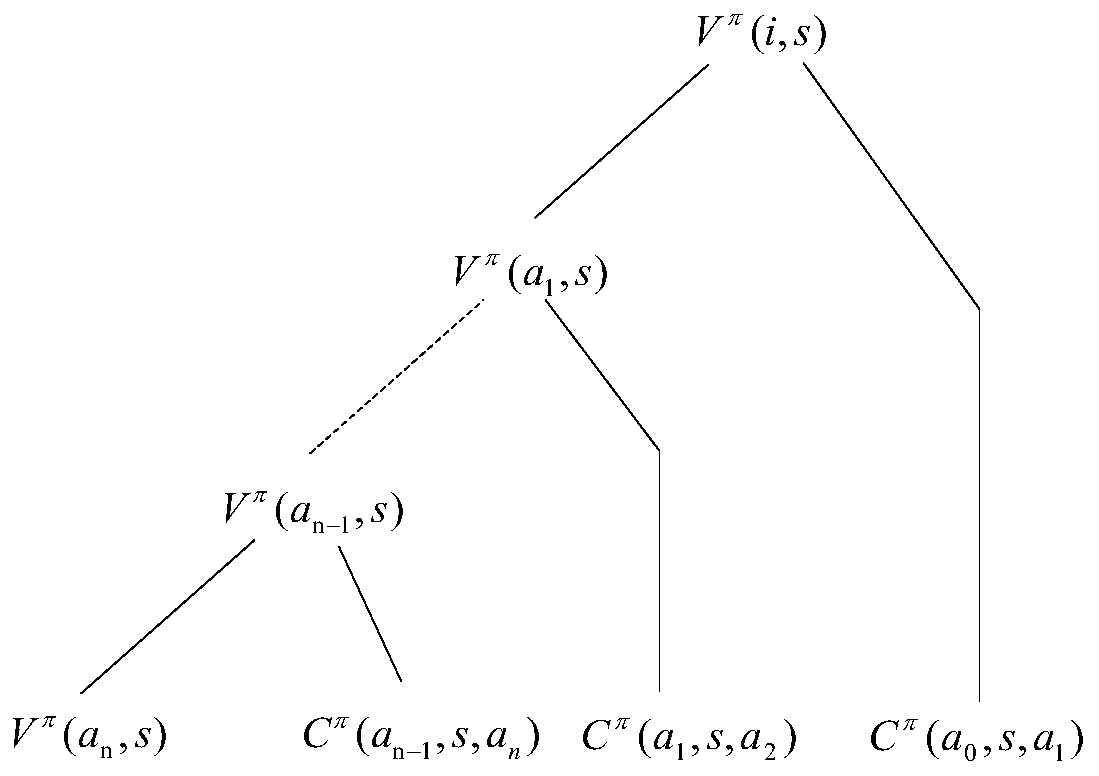

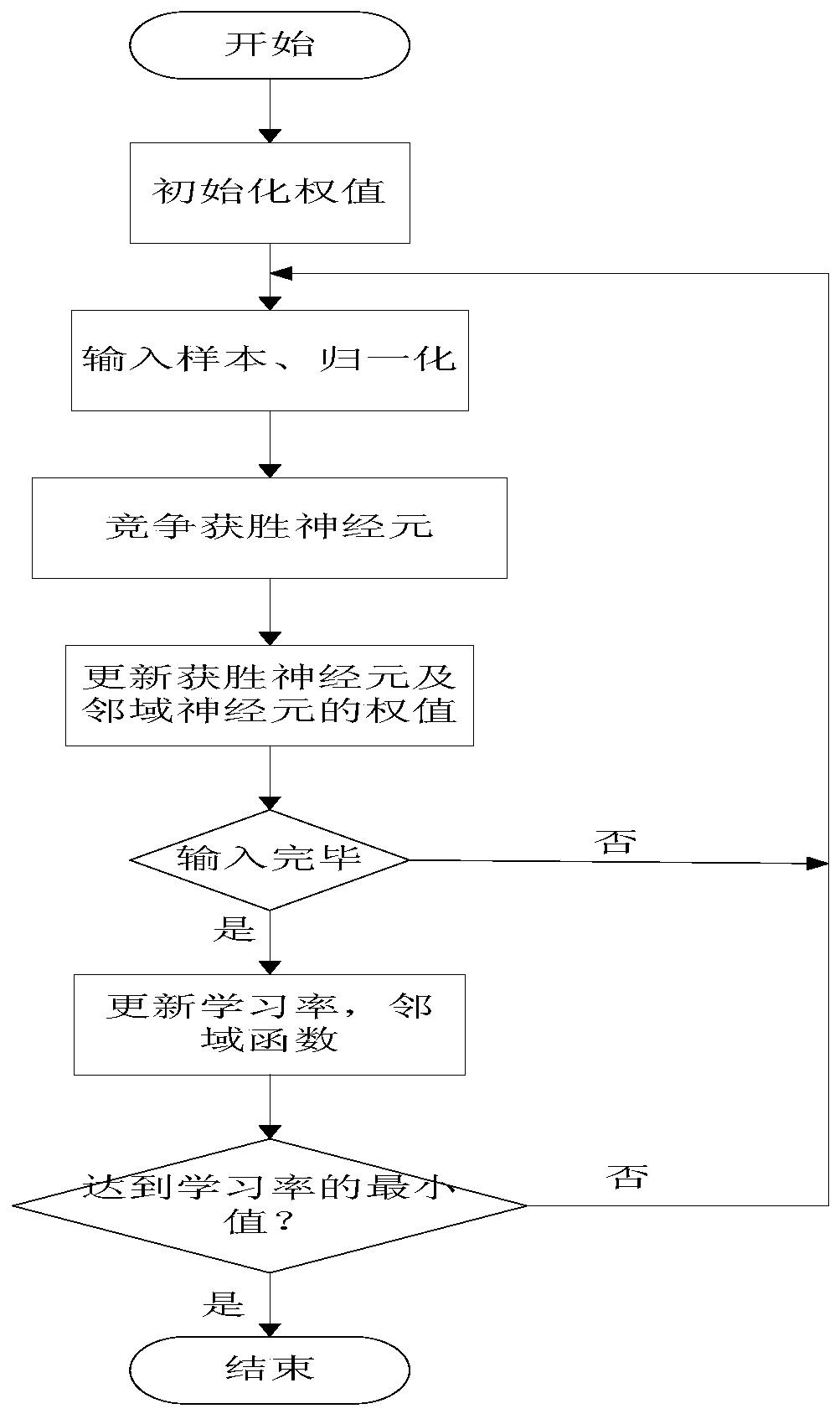

[0024] Using MAXQ and SOM neural network to adaptively adjust the PID parameters, so that the governor can adaptively adjust the speed of the diesel engine. However, the traditional diesel engine speed adjustment algorithm needs to decompose the learning task according to the prior knowledge, and the hierarchical structure of the task decomposition will directly affect the recursive strategy. Good or bad, but in some problems (such as the process of diesel engine speed regulation) the layered particles of the MAXQ algorithm are too rough, and it is difficult to further abstract and decompose the subtasks. In order to solve this problem, the present invention uses the SOM neural network to simulate the abstract mechanism of subtasks (solving the corresponding PID parameter set when the target speed is to be reached at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com