Pay-off frame and pay-off method

A pay-off rack and wire-loading technology, which is used in the transportation of filamentous materials, thin material handling, transportation and packaging, etc., can solve the problem of unsecured wire tension, reduce workload, increase work efficiency, increase The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

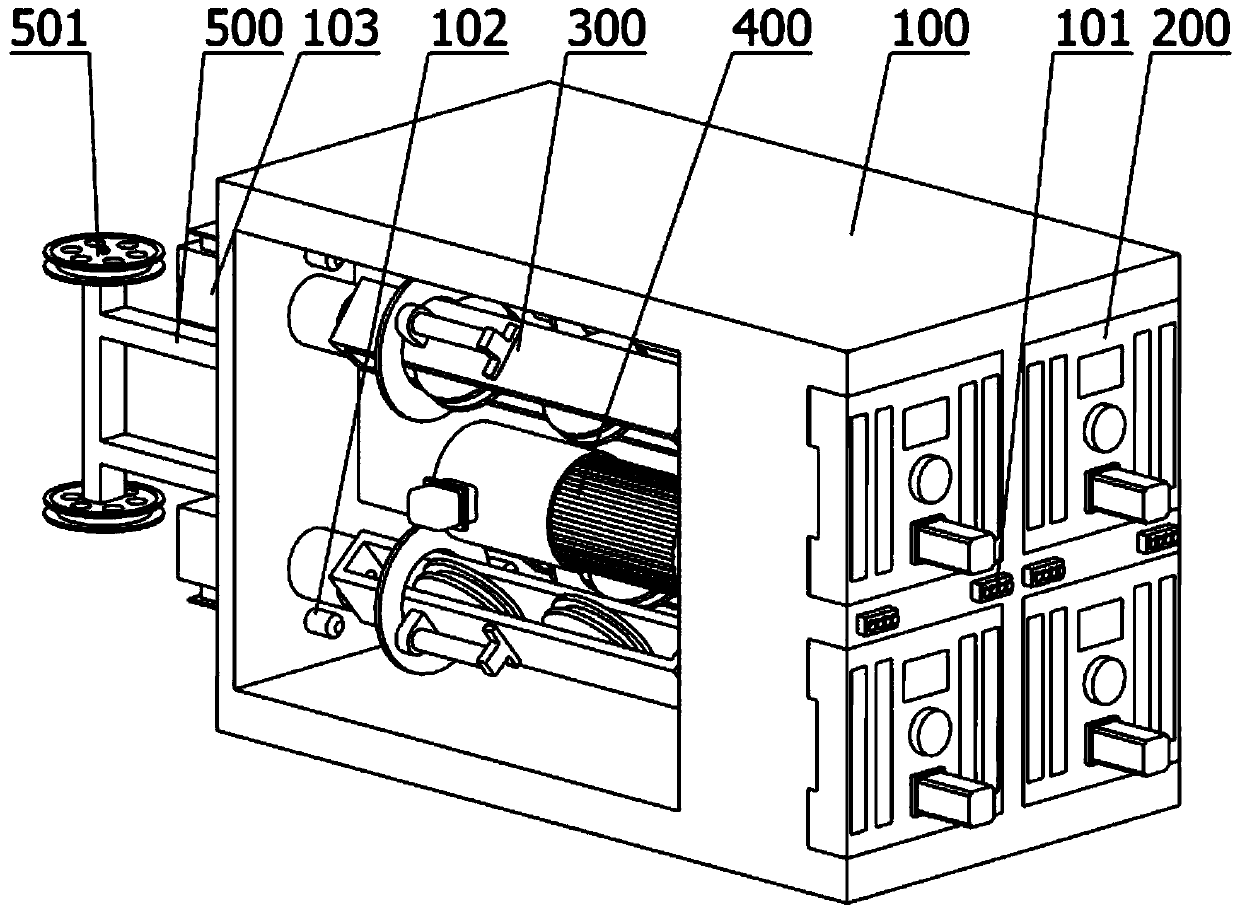

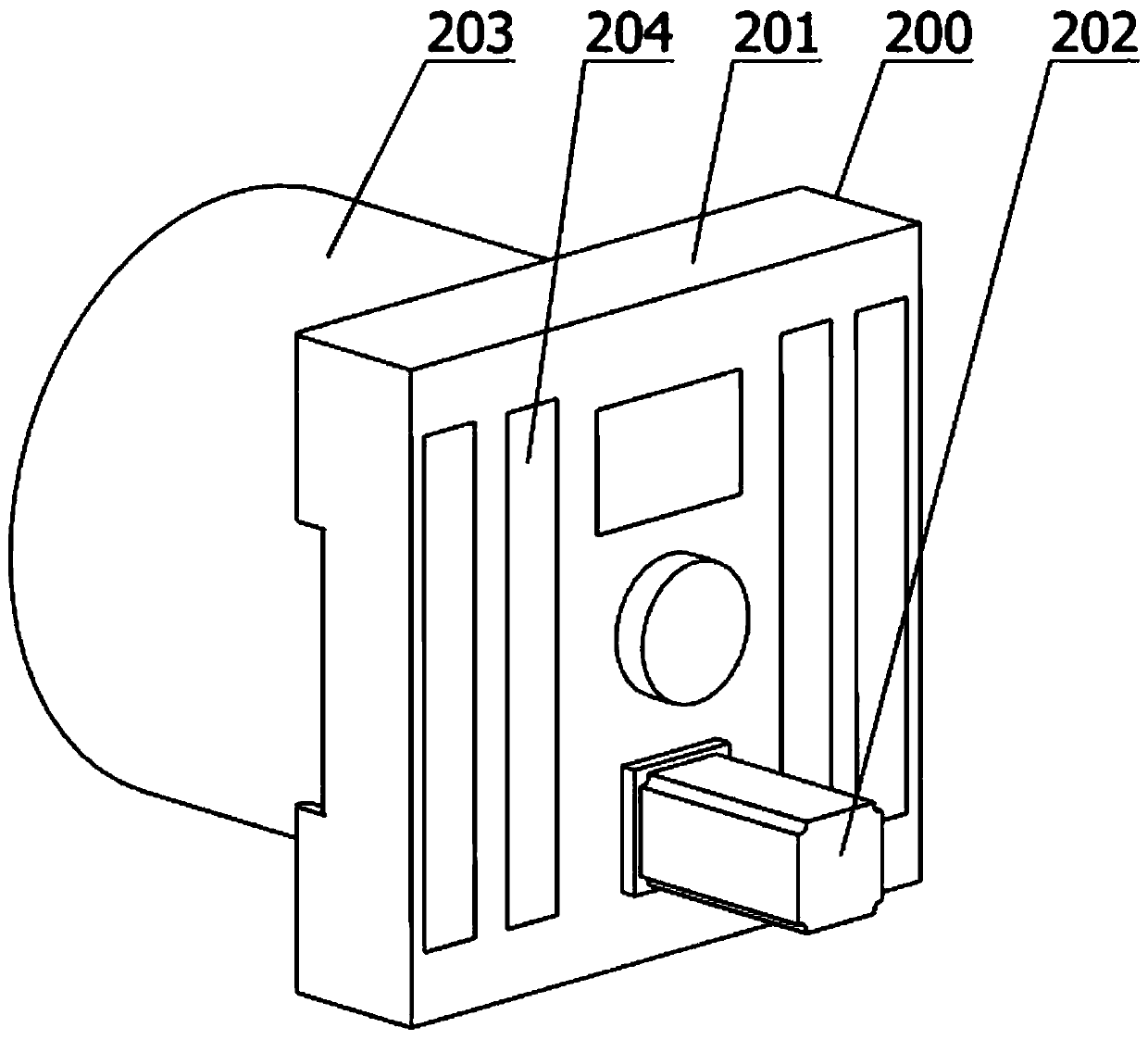

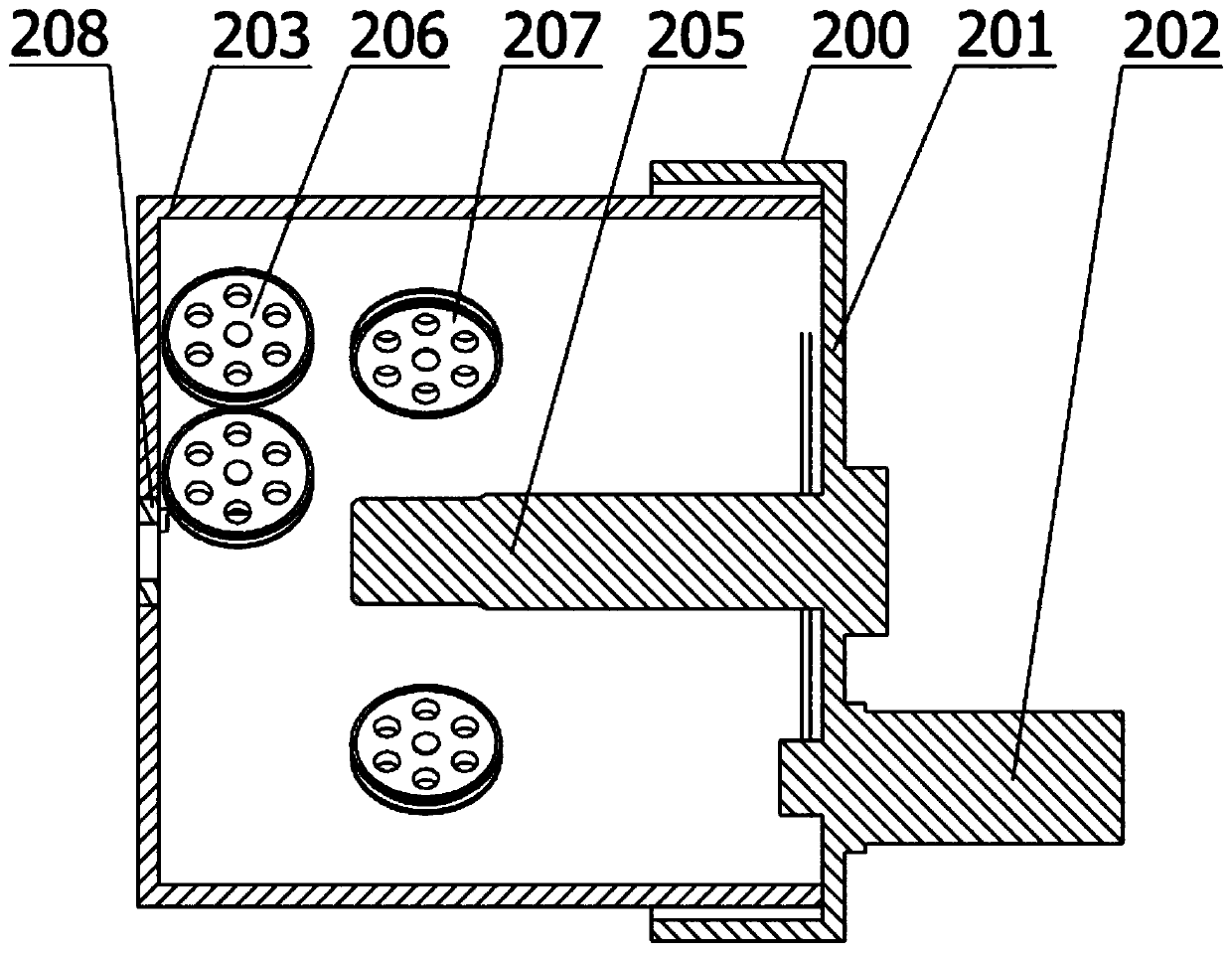

[0048] Such as figure 1 As shown, this embodiment discloses a wire pay-off frame, which includes: a main body, a wire loading frame, a rotating part, and a fixing frame. Main body, there is a working indicator light on the front of the main body, the working indicator light is used to indicate the working state of the pay-off rack, and there is a rotary air joint behind the main body, which can input the compressed air into the cylinder, and the main body has Accommodate space. The fixed frame has two fixed frames, and the upper and lower ends of the fixed frame are provided with outgoing wire guide wheels, which are used to lead out the wires.

[0049] Such asfigure 1 , 2 , 3, and 4, this embodiment discloses a pay-off rack, wherein the wire rack has:

[0050] The wire frame cover is installed on the front of the main body, the wire frame cover is used to install and close the wire reel, and the wire frame cover is equipped with a pay-off motor, which is used to release th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com