Lens brush cleaning machine before mold opening

A cleaning machine and brush technology, applied to other household appliances, optical components, household appliances, etc., can solve the problems of high labor cost, labor and time, etc., and achieve the effect of improving cleaning efficiency and facilitating left and right movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

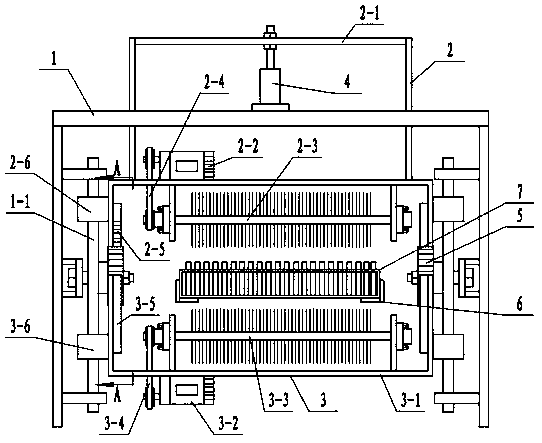

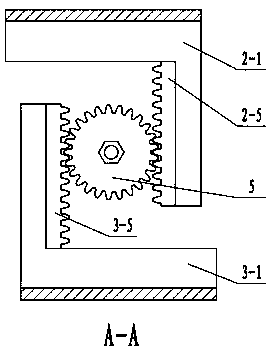

[0011] Depend on figure 1 , figure 2 Known, the present invention is a kind of hairbrush cleaning machine before mold opening of the lens, is made up of outer frame 1, upper roller brush assembly 2, lower roller brush assembly 3, hairbrush pressing cylinder 4, synchronous rotary gear 5, transmission mechanism 6 , lens frame 7, the upper roller brush assembly 2 is installed and fixed above the outer frame 1 through the brush pressing cylinder 4, the lower roller brush assembly 3 is installed below the outer frame 1, and the synchronous rotary gear 5 is symmetrically installed and fixed on the outer frame 1 On the inner sides of the longitudinal beams on the left and right sides, the transmission mechanism 6 passes between the upper roller brush assembly 2 and the lower roller brush assembly 3 and does not interfere with each other. The lens frame 7 is placed on the transmission mechanism 6 and moves left and right through the transmission mechanism 6.

[0012] During work, fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap