An automatic grabbing and palletizing robot for assembly line

A palletizing robot and assembly line technology, applied in the field of automatic identification, can solve problems such as poor flexibility and low identification efficiency, and achieve the effects of preventing accidental dropping, accurate control, and improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

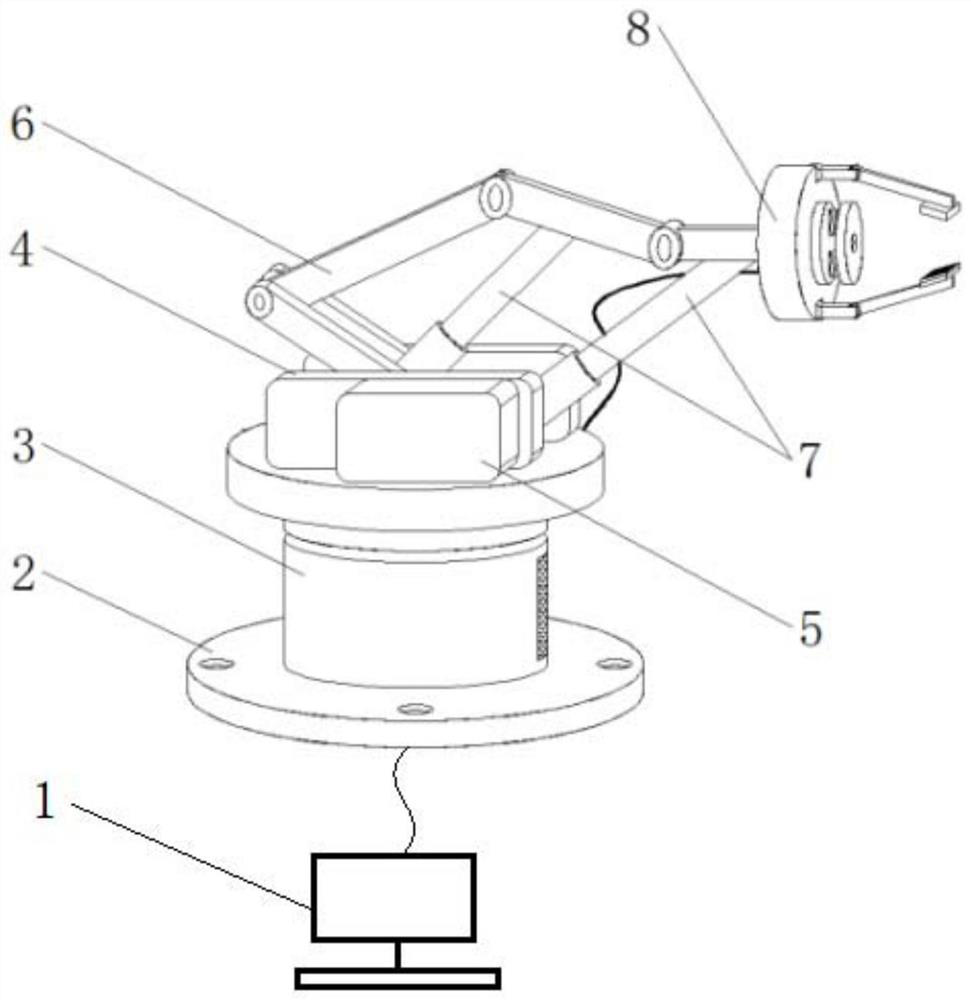

[0031] Example 1, please refer to Figure 1-4 , the present invention provides a technical solution:

[0032] An automatic grabbing and palletizing robot for an assembly line, which includes a host computer 1, a base 2, a console 3, a connecting frame 4, an arm steering gear 5, a small arm connecting rod 6, a large arm connecting rod 7 and a cargo claw 8 .

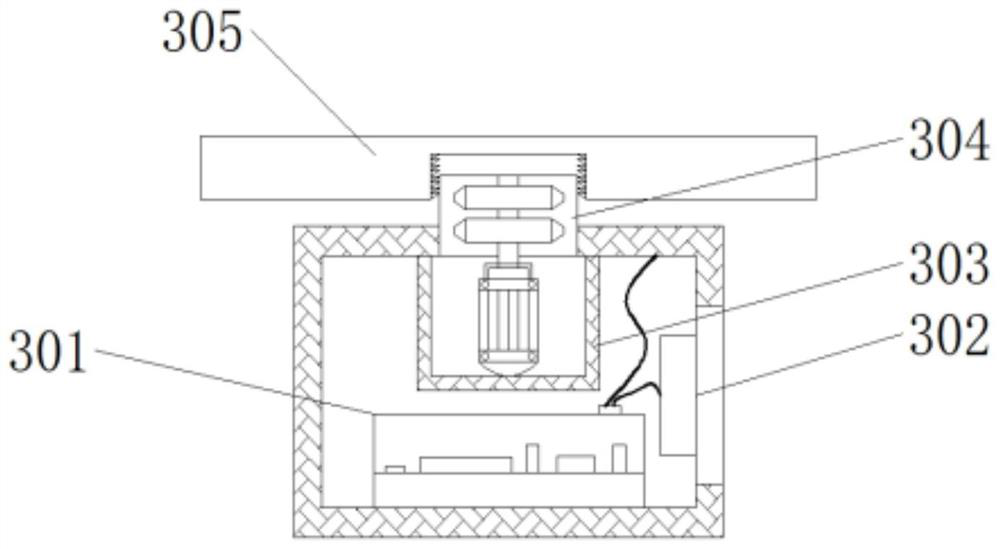

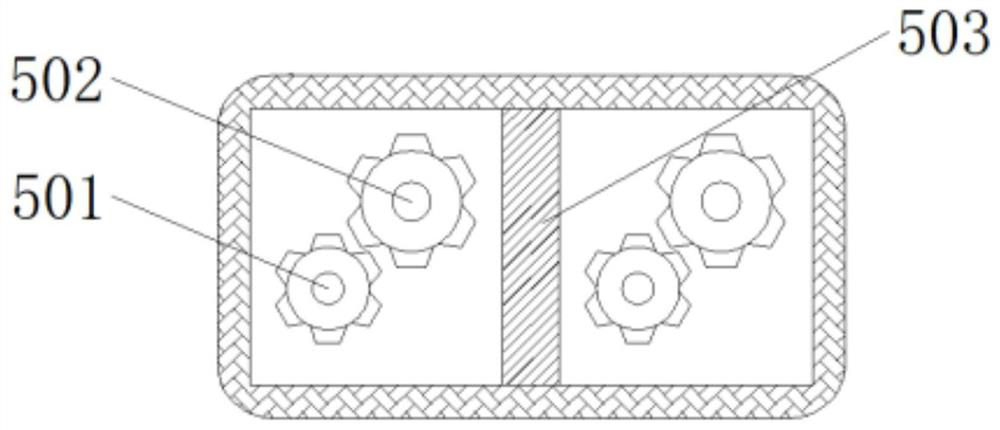

[0033] The base 2 is located at the bottom of the automatic grabbing and palletizing robot, the upper part of the base 2 is fixed with a console 3, the upper part of the console 3 is equipped with a connecting frame 4, and the first end of the small arm connecting rod 6 is connected to the upper arm connecting rod 7. The first end is coaxial and located in the middle of the connecting frame 4, the first side of the connecting frame 4 is fixedly connected with the arm steering gear 5, the big arm connecting rod 7 is gear-linked with the arm steering gear 5, and the small arm connecting rod 6 is multi-stage Link structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com