Terrazzo machine with swing function and for architectural decoration

A technology for architectural decoration and terrazzo, which is applied in the direction of grinding drive devices, machine tools suitable for grinding workpiece planes, grinding machines, etc., and can solve the problems of increasing the load of power parts and limited grinding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

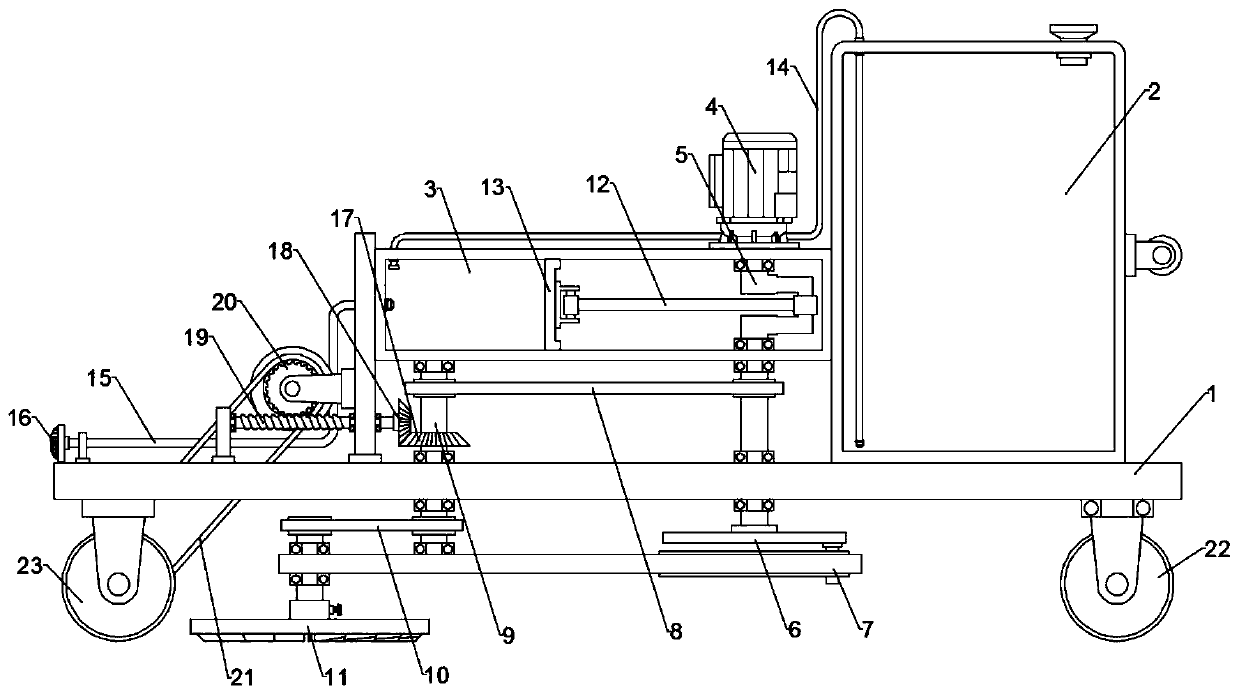

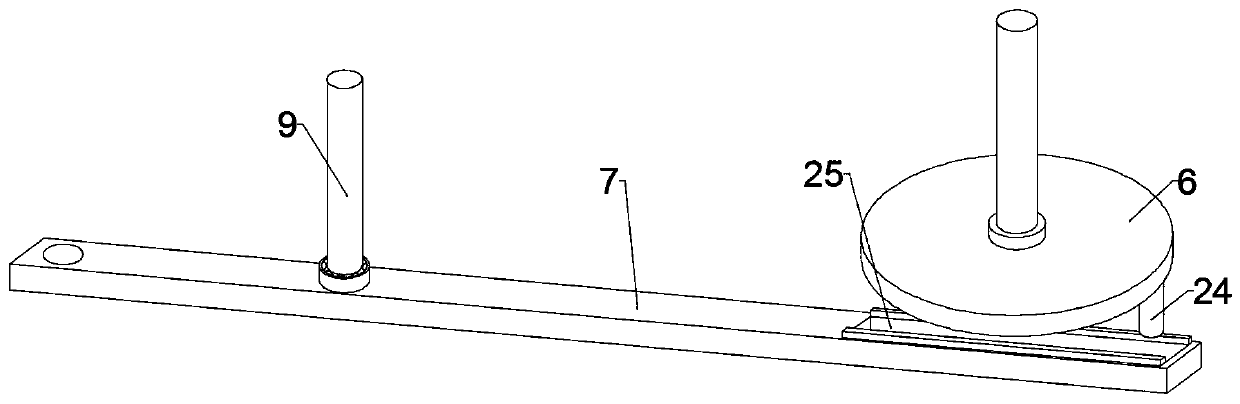

[0021] see Figure 1~3 , in an embodiment of the present invention, a terrazzo machine for architectural decoration with a swing function, comprising a bottom plate 1, a water bucket 2 fixed on the rear of the bottom plate 1, a pump box 3 fixed on one side of the water bucket 2 to pump water, and a The power components on the pump box 3, specifically;

[0022] The power assembly includes a motor 4 flange-mounted on the pump box 3 and a crankshaft 5 connected to the output end of the motor 4 and pierced with the pump box 3 for rotation. The motor 4 is connected to a power supply and a switch through a wire, and the lower part of the crankshaft 5 passes through The bottom plate 1 is connected with bearings, and the bending part of the upper part of the crankshaft 5 is connected to the pumping assembly arranged in the pump box 3. The pump box 3 is connected to the bottom of the bucket 2 through the water inlet pipe 14, and is connected to the outlet through the one-way valve at t...

Embodiment 2

[0026] In order to improve the degree of automation of the device, in another embodiment of the present invention, a building decoration terrazzo machine with a swing function also includes a traveling mechanism, and the traveling mechanism includes a bevel gear set and a worm gear assembly connected to the driven shaft 9 , wherein, the bottom of the front part of the base plate 1 is fixed with a wheel frame, the wheel frame is rotatably connected with the driving wheel 23, the bottom of the rear part of the bottom plate is rotatably connected with another wheel frame, and the rear wheel frame is rotatably connected with a direction wheel 22. The direction wheel 22 controls the traveling direction of the bottom plate 1 , and the drive wheel 23 drives the overall movement.

[0027] Further, the bevel gear set includes a first bevel gear 17 fixedly connected to the driven shaft 9 and a second bevel gear 18 meshing with the first bevel gear 17, wherein the second bevel gear 18 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com