Deceleration strip with warning function

A technology of speed bumps and functions, applied in the field of transportation, can solve the problems of speed bumps, speed reduction, etc., and achieve the effect of convenient use and driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

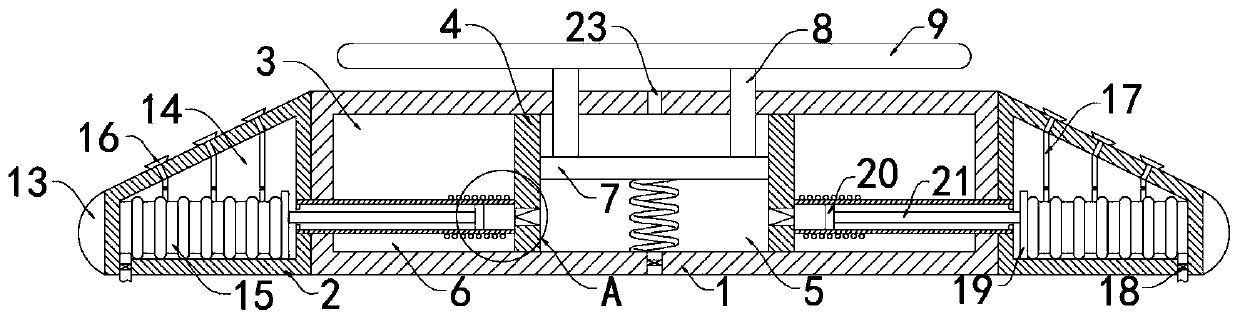

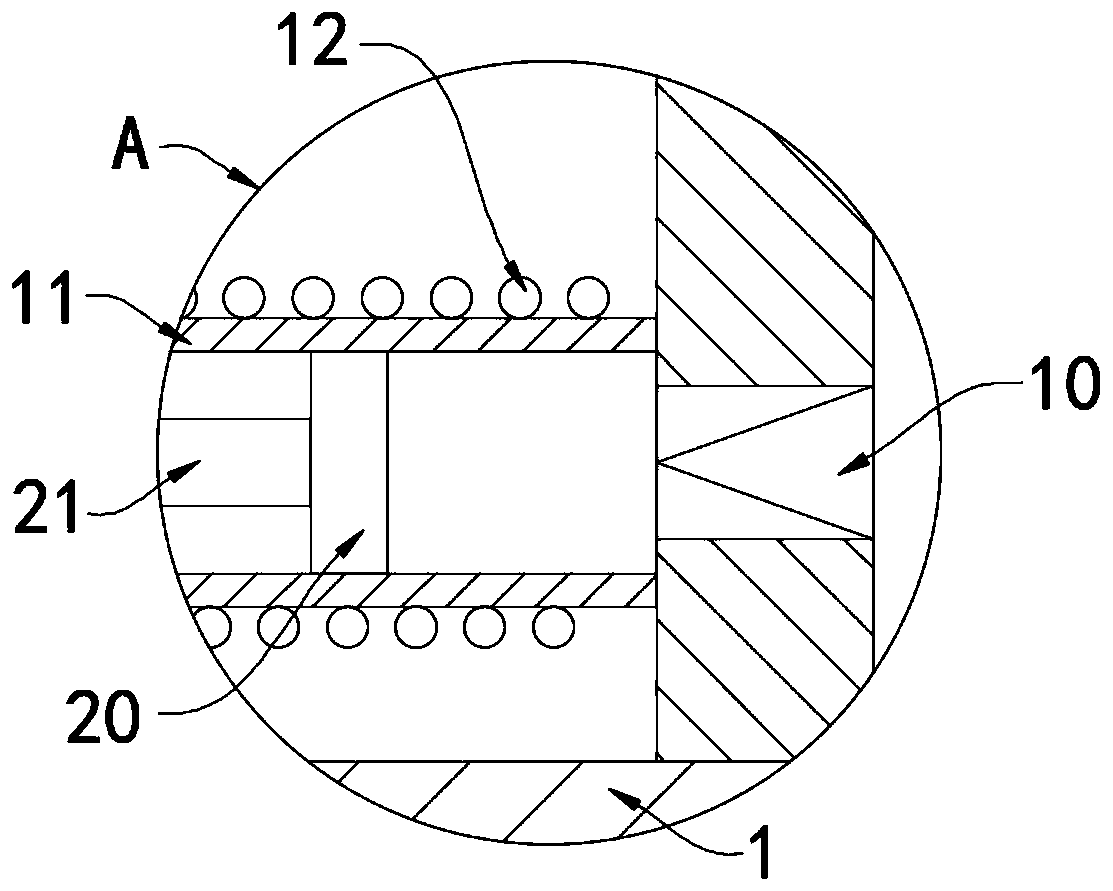

[0024] Such as Figure 1-3 As shown, a deceleration belt with a warning function includes a deceleration briquetting block 1, deceleration beading bars 2 are fixedly connected to the side walls on both sides of the deceleration briquetting block 1, and a cavity 3 is provided in the deceleration briquetting block 1, and the cavity 3 The internal fixed connection has two fixed plates 4 that are both vertically arranged. The two fixed plates 4 divide the cavity 3 into a deceleration chamber 5 located in the middle and a transmission chamber 6 located on both sides. The deceleration chamber 5 is sealed and slidably connected with a horizontal For the sliding plate 7 provided, it should be noted that the upper side wall of the deceleration briquetting block 1 is provided with a communication port 23 communicating with the deceleration chamber 5, and the communication hole 23 can balance the air pressure above the sliding plate 7, so that the sliding plate 7 can move up and down free...

Embodiment 2

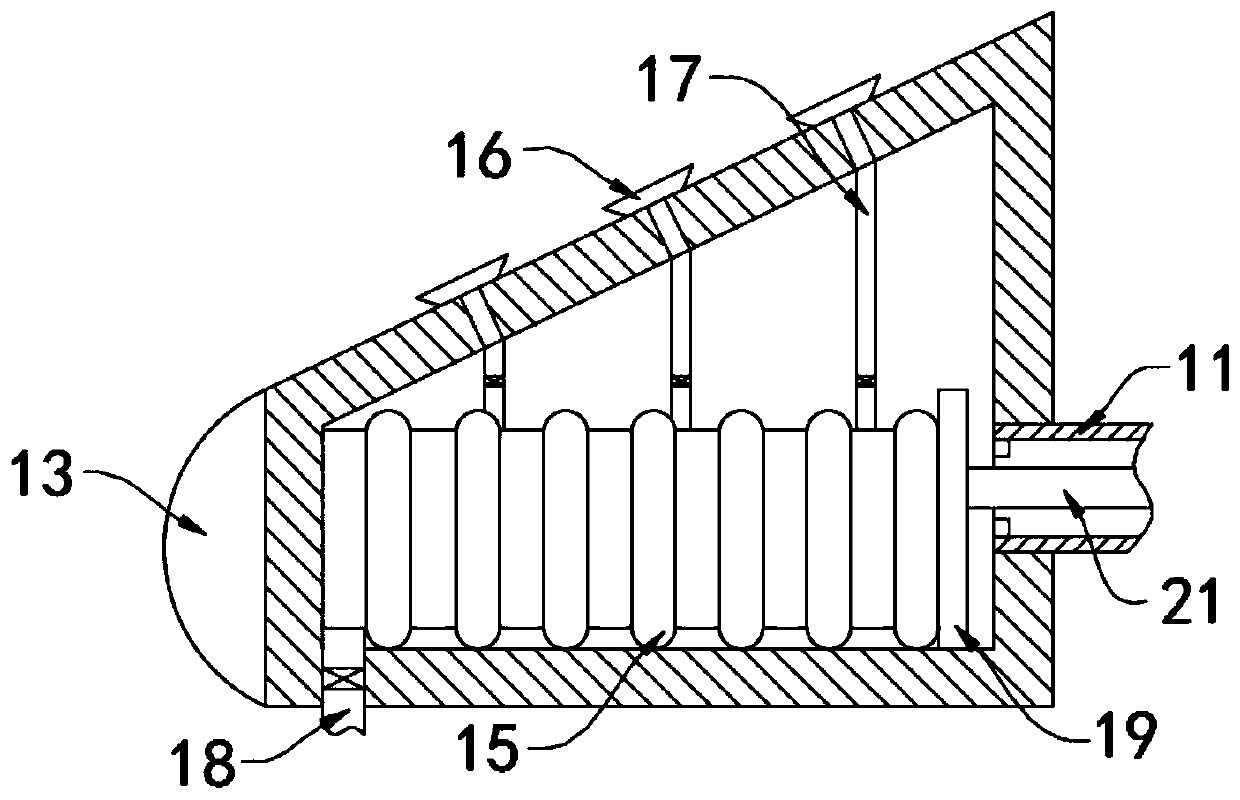

[0035] Such as Figure 4As shown, the difference between this embodiment and Embodiment 1 is that: the upper side wall of the deceleration bezel 2 is fixedly connected with a plurality of reflective strips 22, and a plurality of sprinkler heads 16 are arranged between the plurality of reflective strips 22 and are lower than the reflective strips. Bar 22 is set.

[0036] In this embodiment, the reflective strip 22 arranged on the side wall of the deceleration bead 2 can enable the driver to see the deceleration belt in advance at night, thereby decelerating as early as possible to ensure driving safety. The sprinkler head 16 is set lower than the reflective strip 22. When the automobile rolls on the deceleration bead 2, it will only contact the reflective strip 22, which can effectively protect the sprinkler head 16.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com