Automatic processing production line of cylinder barrel

A production line and cylinder technology, applied in metal processing and other directions, can solve the problems of low production efficiency and high production costs, and achieve the effects of reducing manual handling and transfer, improving work efficiency and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

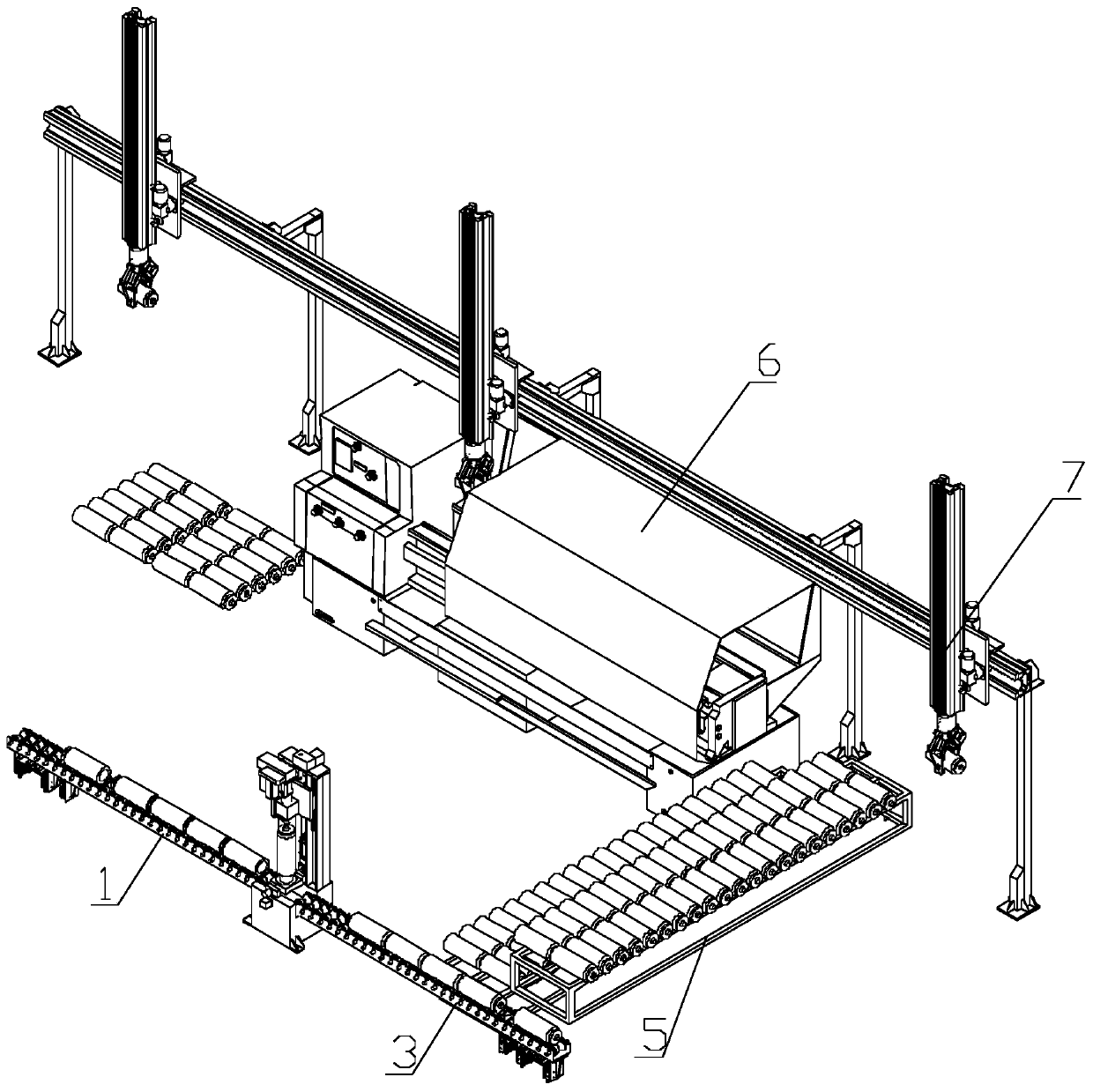

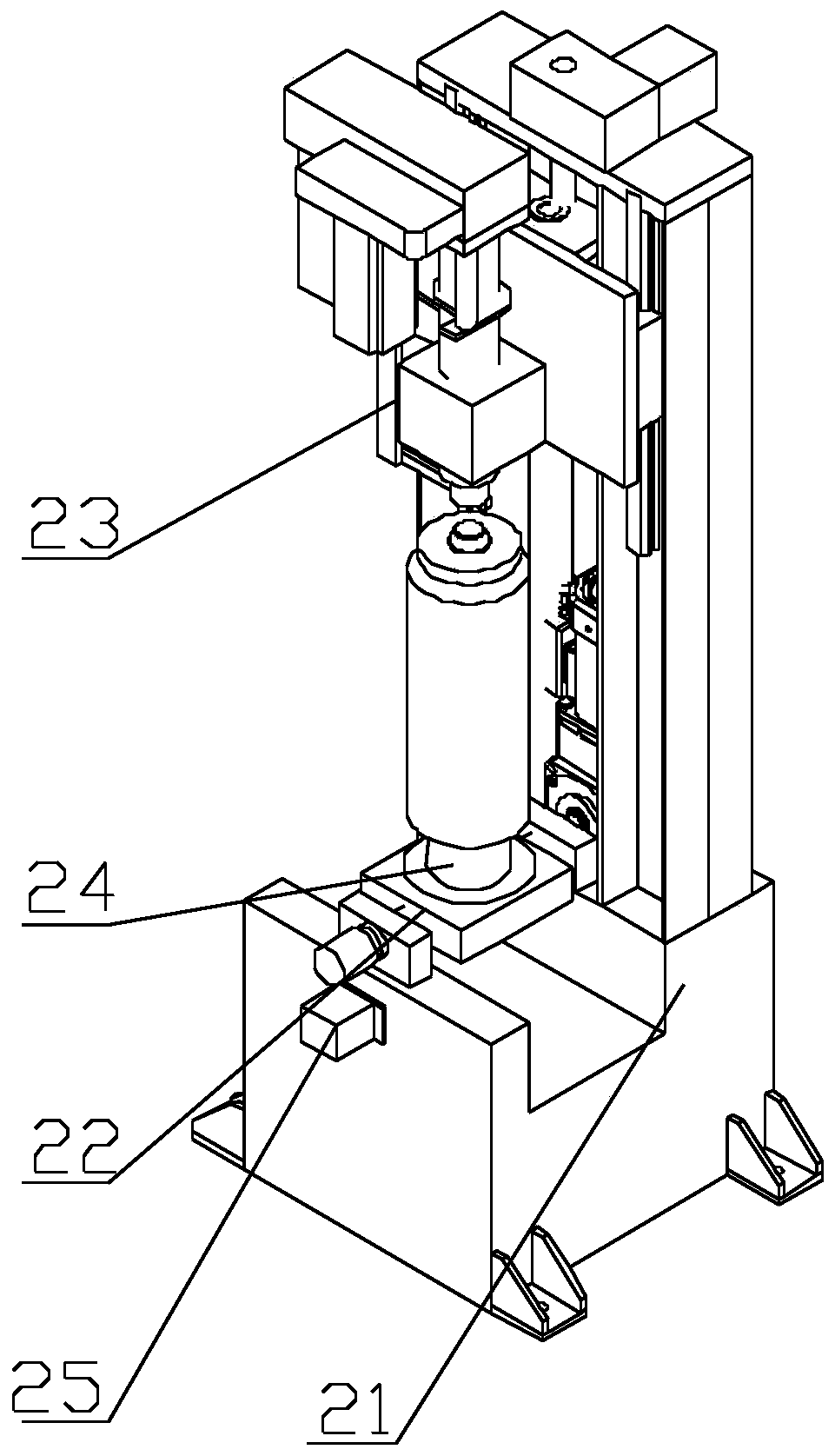

[0022] Such as Figures 1 to 5 as shown, figure 1 It is a structural schematic diagram of a cylinder barrel automatic processing production line proposed by the present invention.

[0023] refer to Figures 1 to 5 , a kind of automatic cylinder processing production line that the present invention proposes, comprises: feeding conveying line 1, central hole processing host, unloading conveying line 3, unloading mechanism 4, material storage rack 5, outer cylinder processing host 6, feeding Agency 7;

[0024] The feeding conveying line 1 and the unloading conveying line 3 are respectively located on both sides of the central hole processing main machine. The feeding conveying line 1 is provided with a plurality of rotatably installed feeding conveying rollers 11, and the feeding conveying rollers 11 are perpendicular to the feeding The conveying direction is set and a plurality of feeding conveying rollers 11 are arranged sequentially along the conveying direction of the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com