Pulse washing device for scale impurities in high-power motor cooler

A motor cooling and pulse cleaning technology, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of inability to guarantee the normal operation of the motor, affecting the working effect of the cooler, and poor cooling effect of the cooler, etc. problems, to achieve the effect of wide use environment, simple design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

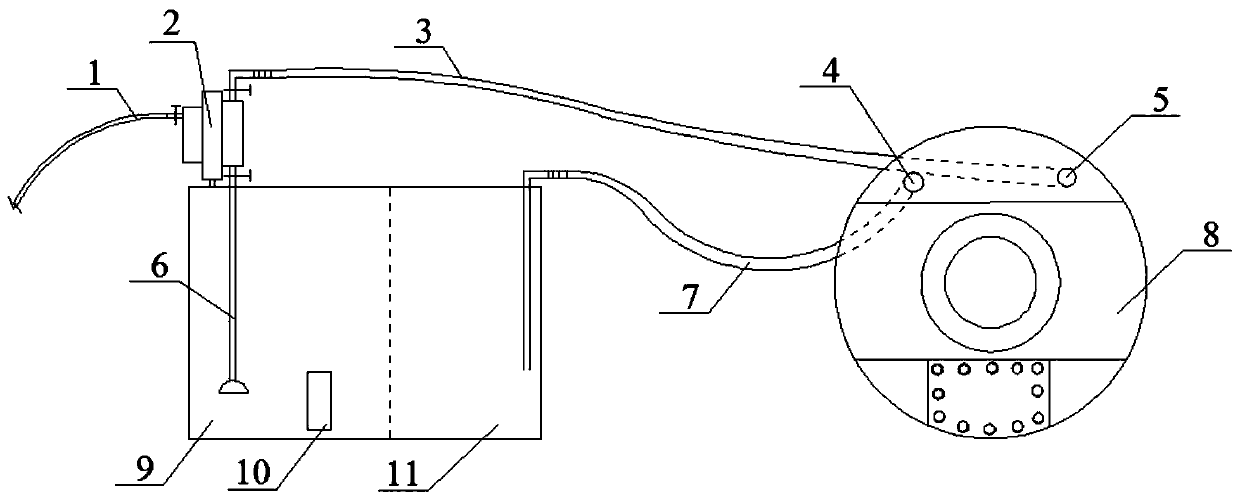

[0026] The invention discloses a pulse cleaning device for scaling impurities inside a high-power motor cooler, such as figure 1 As shown, it includes a dispensing container 9, which is used to hold the scale impurity softener. The dispensing container 9 can be selected or designed according to actual needs. When the use environment is limited, it can even be used for operations such as buckets, as long as the liquid preparation is satisfied. .

[0027] The scale impurity softener can realize the softening of scale impurities. Due to the problem of the working environment, in order to prevent the motor cooler from being corroded, the softener should not be too corrosive, and edible citric acid is preferably used.

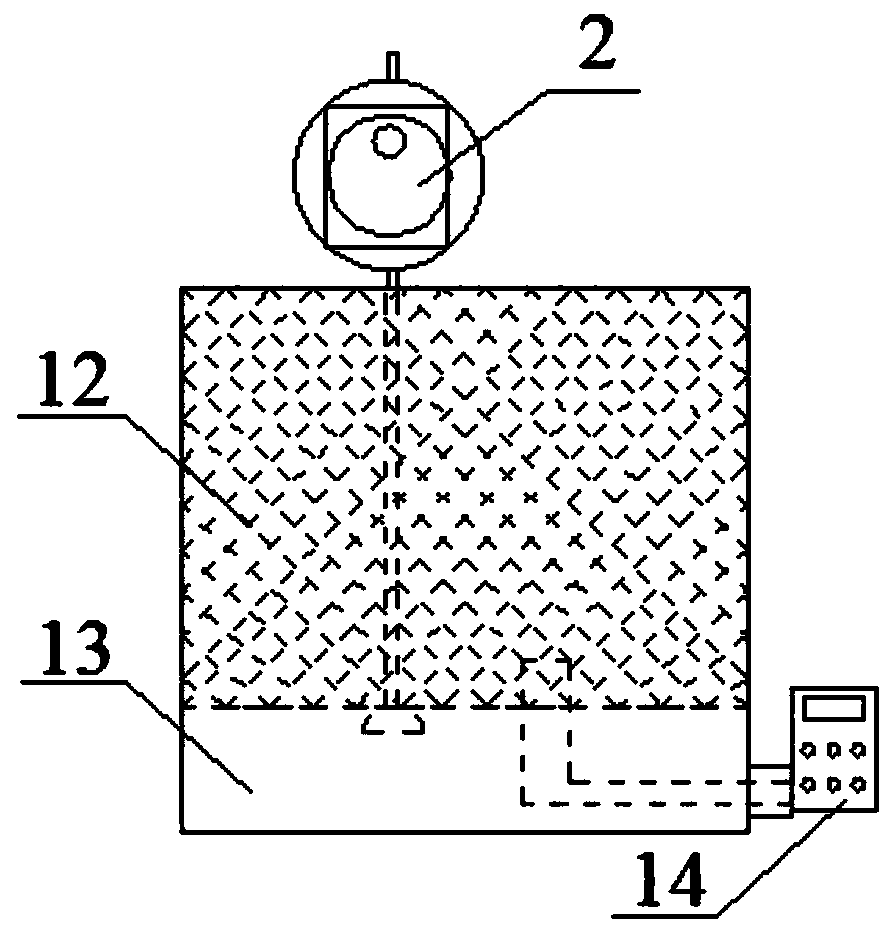

[0028] Such as figure 2 As shown, a heating pipe 10 is installed at the inner bottom of the medicine dispensing container 9 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com