Greening method for high steep rock slope in mining pit

A rocky slope, high and steep technology, applied in botany equipment and methods, excavation, horticulture, etc., can solve problems such as inability to use soil-covering planting technology, inability to carry out grading operations, and shake-off of sprayed substrates, etc., to achieve vegetation Low maintenance cost, reduced post-irrigation, and low greening cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

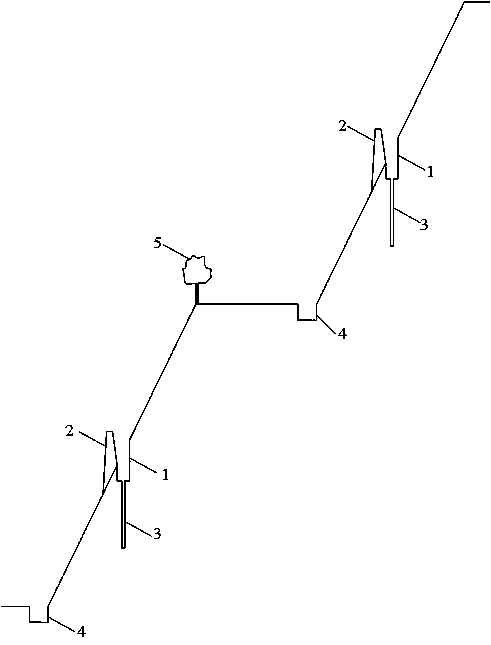

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for greening high and steep rocky slopes in mining pits, comprising the following steps:

[0033] (1) Manually remove the pumice on the slope surface, and clean the cracks on the slope surface with high-pressure air;

[0034] (2) Grouting the cracks on the slope surface, the grout is prepared from the following mass ratio of raw materials: P.O42.5 Portland cement: water glass: iron tailings powder: epoxy resin = 2:1:0.8: 0.5;

[0035] (3) After the grouting grout in step (2) is solidified and stable, drill holes along the vertical direction of the slope. The drilling depth is 1.2m. The distance adjacent to the quincunx is 5m, then pour M40 cement mortar, and insert anchor cables;

[0036] (4) Carry out mechanical grooves along the slope every 4~5m perpendicular to the horizontal plane, and then drill holes perpendicular to the horizontal plane at the bottom of the groove. The diameter of the drilling hole is 8cm, the drilling depth i...

Embodiment 2

[0042] This embodiment provides a method for greening high and steep rocky slopes in mining pits, comprising the following steps:

[0043] (1) Manually remove the pumice on the slope surface, and clean the cracks on the slope surface with high-pressure air;

[0044] (2) Grouting the cracks on the slope surface, the grout is prepared from the following mass ratio of raw materials: P.O42.5 Portland cement: water glass: iron tailings powder: epoxy resin = 2:1:0.8: 0.5;

[0045] (3) After the grouting grout in step (2) is solidified and stable, drill holes along the vertical direction of the slope. The drilling depth is 1.3m. The distance adjacent to the plum blossom shape is 8m, then pour M40 cement mortar, and insert anchor cables;

[0046] (4) Carry out mechanical grooves along the slope every 4~5m perpendicular to the horizontal plane, and then drill holes perpendicular to the horizontal plane at the bottom of the groove. The width of the groove is 25cm, and the depth of the...

Embodiment 3

[0052] This embodiment provides a method for greening high and steep rocky slopes in mining pits, comprising the following steps:

[0053] (1) Manually remove the pumice on the slope surface, and clean the cracks on the slope surface with high-pressure air;

[0054] (2) Grouting the cracks on the slope surface, the grout is prepared from the following mass ratio of raw materials: P.O42.5 Portland cement: water glass: iron tailings powder: epoxy resin = 2:1:0.8: 0.5;

[0055] (3) After the grouting grout in step (2) is solidified and stable, drill holes along the vertical direction of the slope. The drilling depth is 1.5m. The distance adjacent to the quincunx is 10m, then pour M40 cement mortar, and insert anchor cables;

[0056] (4) Carry out mechanical grooves along the slope every 4~5m perpendicular to the horizontal plane, and then drill holes perpendicular to the horizontal plane at the bottom of the groove. The width of the groove is 30cm, and the depth of the upper ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com