Polarizer with TAC layer arranged on one side and preparation method thereof

A polarizer, single-sided technology, applied in the field of polarizers, can solve problems such as the inability to meet the market demand for thinner polarizers, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of a polarizer with a TAC layer arranged on one side of the present invention is characterized in that it comprises the following steps:

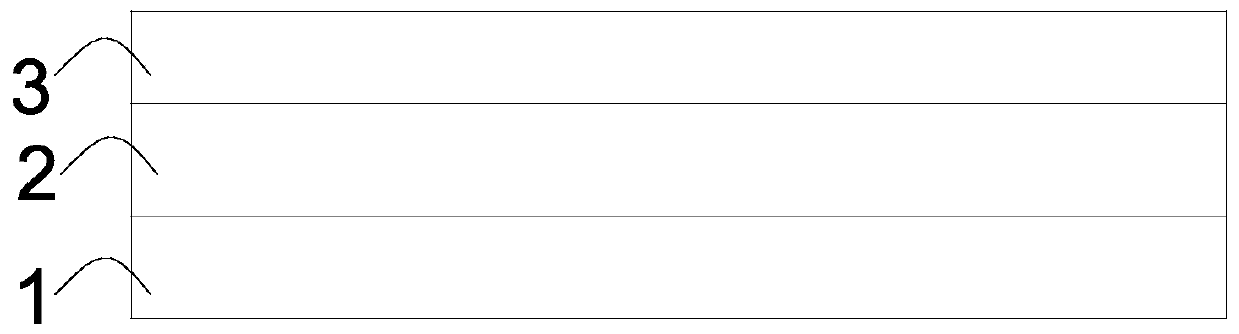

[0048] Such as Figure 1-2 , Figure 4-5As shown, the steps of compounding: open the transfer film layer 3, and compound it with the PVA layer 2 and the TAC layer 1, and the transfer film layer 3 and the TAC layer 1 are attached to both sides of the PVA layer 2 respectively to obtain the first composite piece;

[0049] The step of tearing off the transfer film layer: tearing off the transfer film layer 3 on the first composite sheet to obtain the second composite sheet 10;

[0050] The step of corona: corona treatment is performed on the exposed PVA layer 2 of the second composite sheet 10 to obtain the second composite sheet after corona;

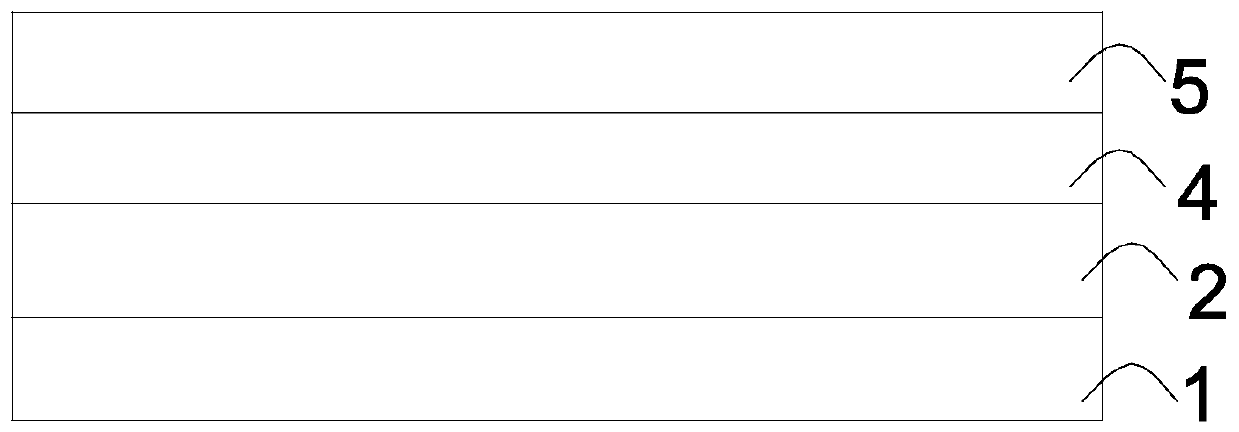

[0051] The step of coating the PSA layer: coating the first PSA layer 4 on the protective layer 5, and then attaching it to the PVA layer 2 of the second composite sheet...

Embodiment approach

[0052] As a further embodiment, the following steps are included:

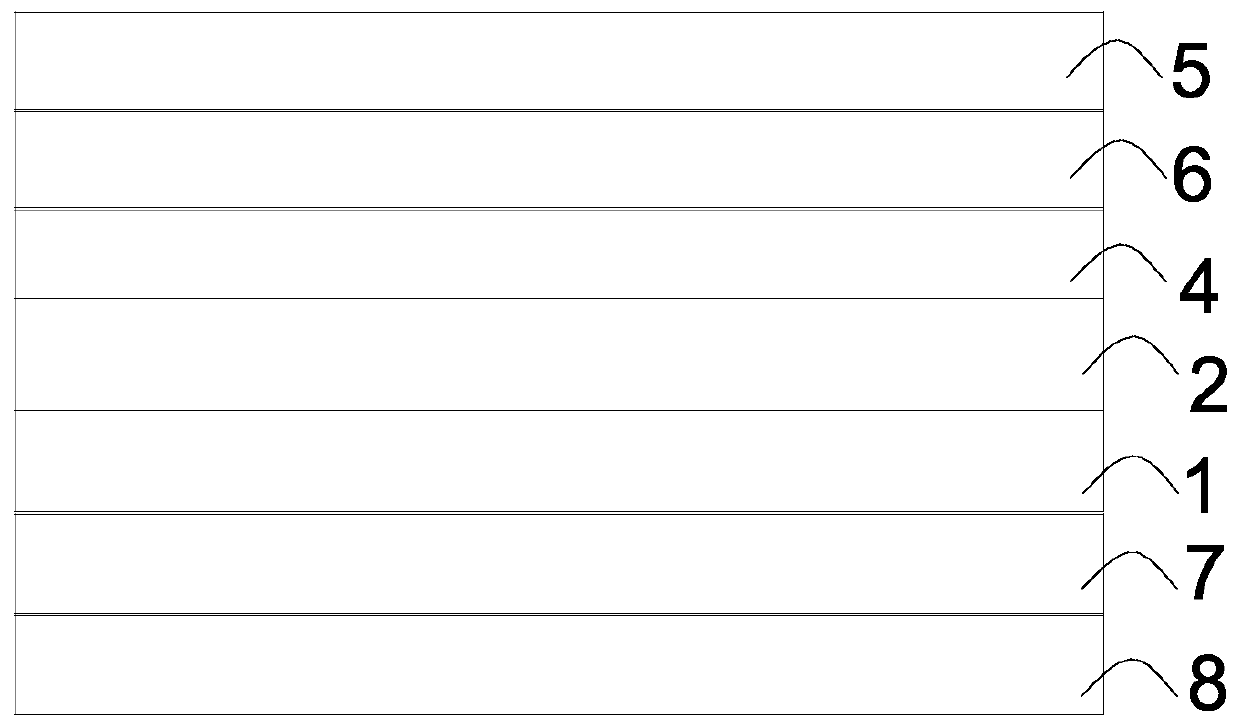

[0053] like Figure 1-5 As shown, the steps of compounding: open the transfer film layer 3, and compound it with the PVA layer 2 and the TAC layer 1, and the transfer film layer 3 and the TAC layer 1 are attached to both sides of the PVA layer 2 respectively to obtain the first composite piece;

[0054] The step of tearing off the transfer film layer: tearing off the transfer film layer 3 on the first composite sheet to obtain the second composite sheet 10;

[0055] The step of corona: corona treatment is performed on the exposed PVA layer 2 of the second composite sheet 10 to obtain the second composite sheet after corona;

[0056] The step of coating the PSA layer: coating the first PSA layer 4 on the PVA layer of the second composite sheet after corona; then attaching the brightness enhancement film layer 6 to the first PSA layer 4; then applying the brightness enhancement film The protective layer 5 is ...

Embodiment 1

[0064] like figure 2 As shown, the polarizer with a TAC layer on one side includes a protective layer 5 , a first PSA layer 4 , a PVA layer 2 and a TAC layer 1 that are laminated in sequence.

[0065] The preparation method of the above-mentioned polarizer with a TAC layer arranged on one side comprises the following steps:

[0066] Composite steps: open the transfer film layer 3, and compound it with the PVA layer 2 and the TAC layer 1, and attach the transfer film layer 3 and the TAC layer 1 to both sides of the PVA layer 2 respectively to obtain the first composite sheet;

[0067] The TAC layer and the PVA layer are bonded with water glue, and the flow rate of the water glue is 10kg / h;

[0068] The step of tearing off the transfer film layer: tearing off the transfer film layer 3 on the first composite sheet to obtain the second composite sheet 10;

[0069] The step of corona: corona treatment is performed on the exposed PVA layer 2 of the second composite sheet 10 to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com