Toxic gas explosion box testing device and testing method thereof

A testing device and a technology for toxic gas, which are applied in the field of explosive toxic gas testing equipment, can solve the problems of inability to meet the test conditions of large charge and large diameter charge of non-detonator sensitivity explosives, cannot simulate the explosive environment of explosives, etc., and can expand the measured charge , the effect of reducing the measurement conditions

Active Publication Date: 2019-09-17

CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

View PDF11 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It can be seen that the existing devices cannot simulate the explosion environment of explosives under normal use conditions, so as to objectively reflect the content of toxic gases produced after explosive explosions, and cannot meet the test conditions for large-dose, large-diameter charges of explosives without detonator sensitivity.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0072] The engineer of Xi'an Junchao Electromechanical Equipment Co., Ltd. introduced the basic knowledge of the toxic gas explosion box, and at the same time gave a brief introduction and training on the basic operation and daily maintenance of the explosion box.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

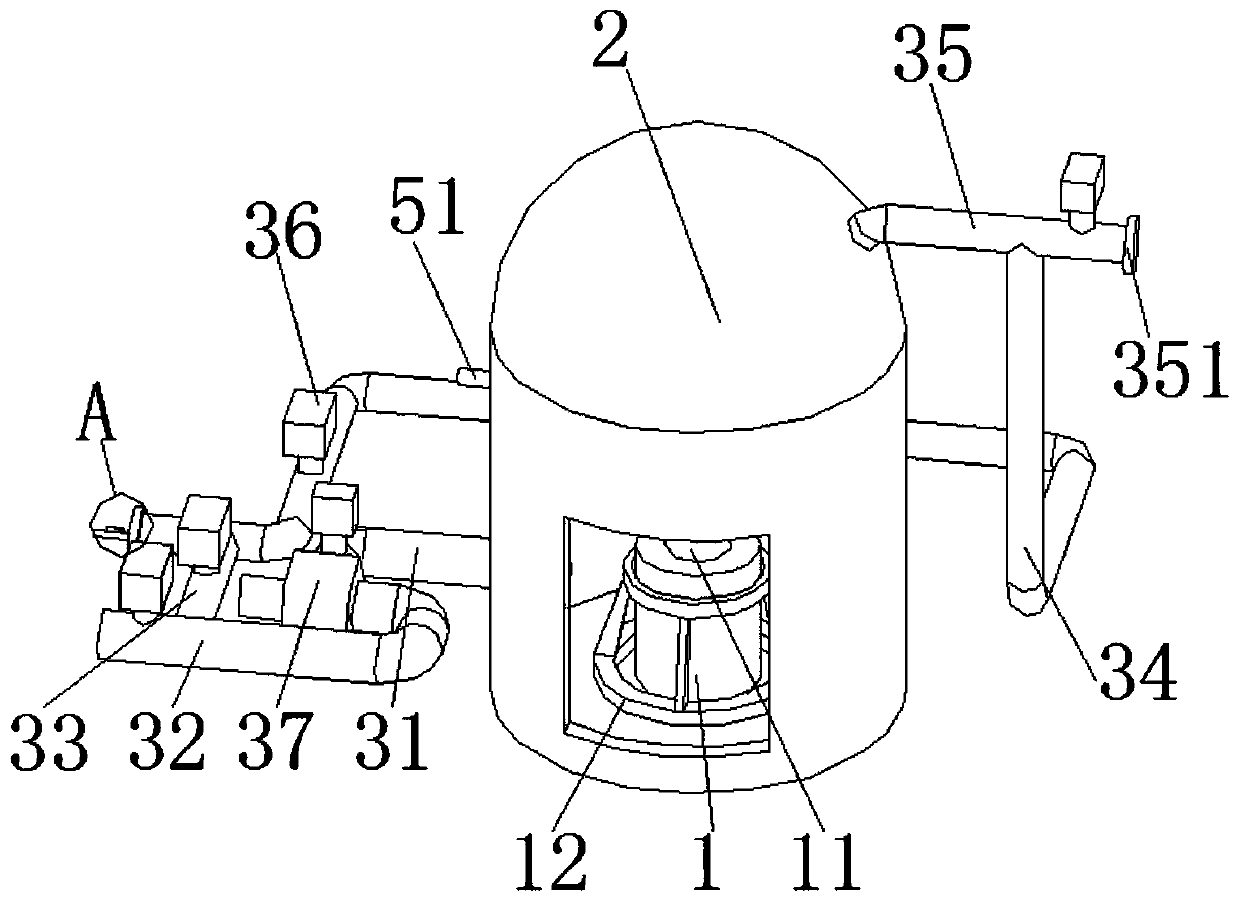

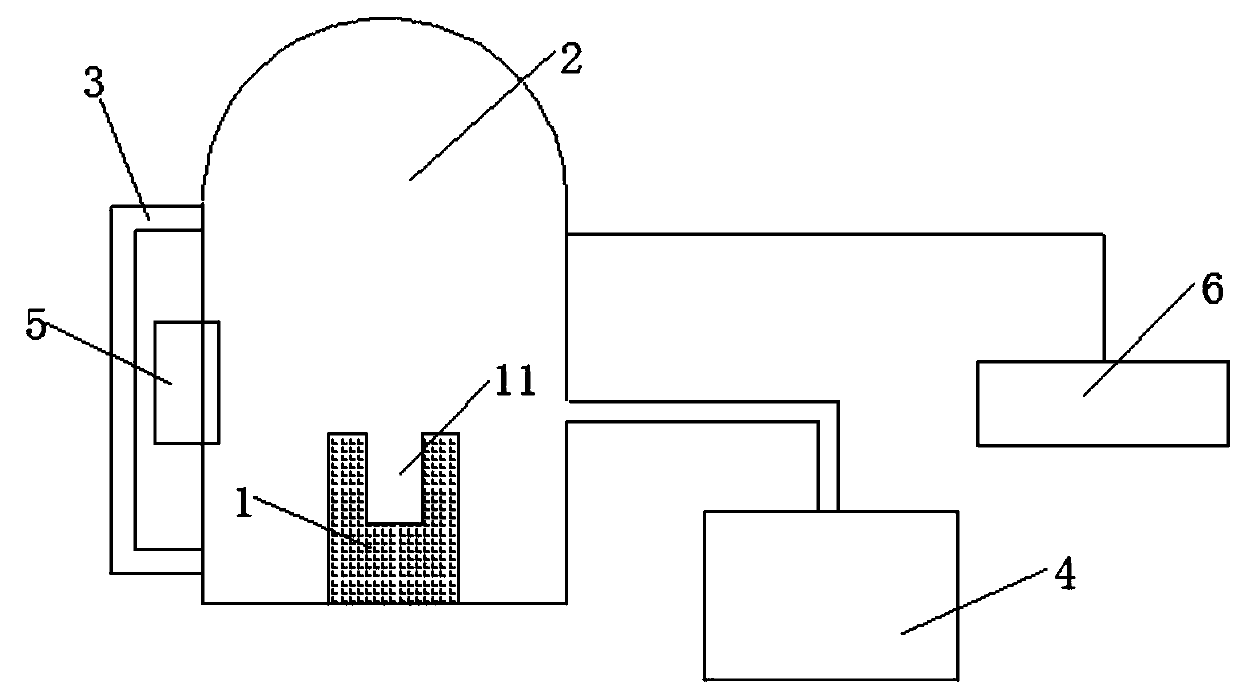

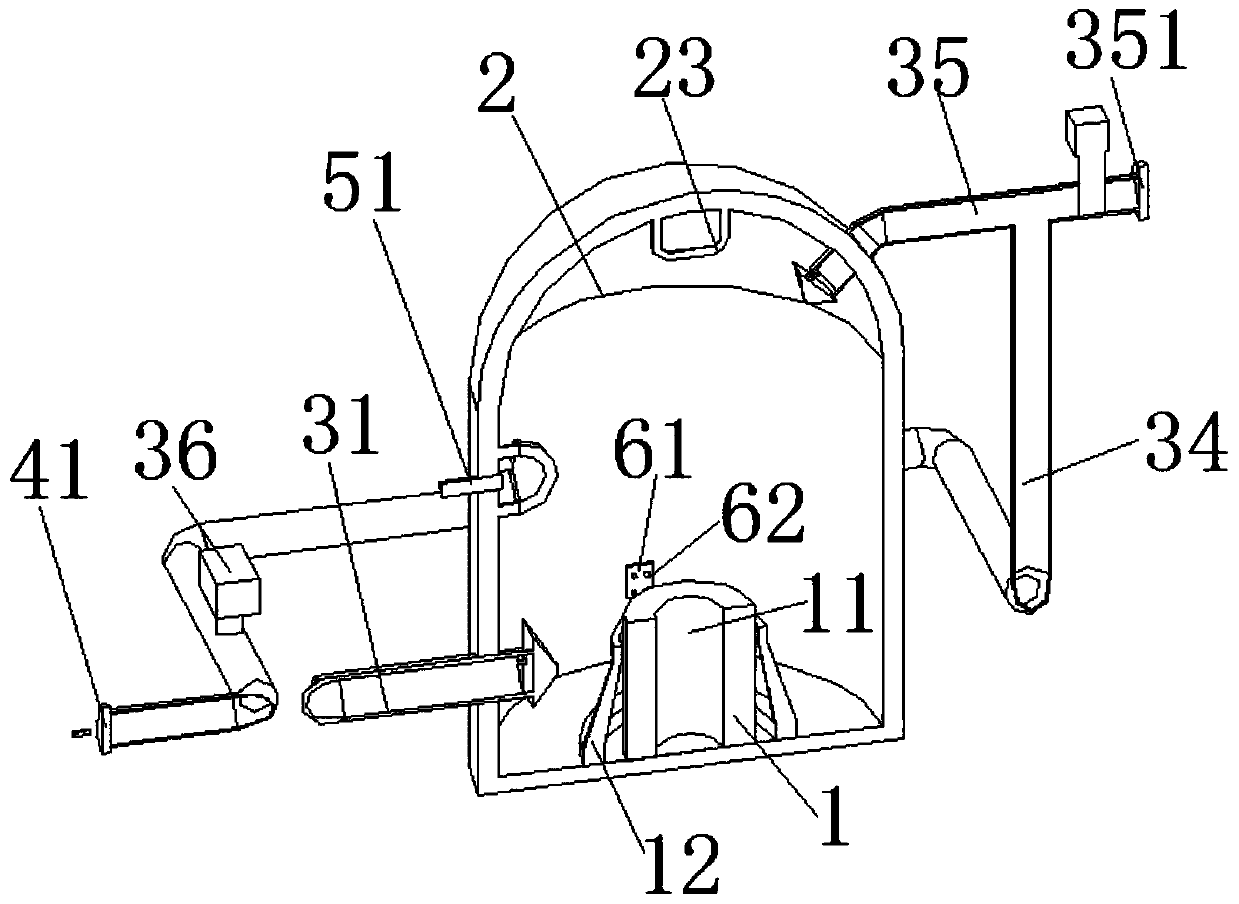

The invention discloses a toxic gas explosion box testing device and a testing method thereof. The toxic gas explosion box testing device comprises an explosion box, a mixing mechanism, an collecting and analyzing mechanism and an exhaust mechanism; the explosion box has an explosion chamber, and a carronade for placing a sample is arranged in the explosion chamber; the mixing mechanism comprises a mixing pipeline, both ends of the mixing pipeline are connected with the explosion chamber, and an air compressor and a pneumatic valve are connected to the mixing pipeline; and the gas collecting mechanism comprises a collecting pipeline and a vent valve, and one end of the collecting pipeline communicates with the mixing pipeline. By means of the cooperation of the mixing mechanism, the collecting and analyzing mechanism and the exhaust mechanism, an explosive is exploded under a normal pressure, the test dose can reach 500g TNT equivalent, the charging diameter can reach 100mm, the blank of domestic explosive toxic gas generation amount test is filled, an emulsion explosive is applied to the test, and a scientific means is provided for testing the toxic gas contents of explosives without cap sensitivity.

Description

technical field [0001] The invention relates to the technical field of explosive toxic gas testing equipment, in particular to a toxic gas explosion box testing device and a testing method thereof. Background technique [0002] The toxic gas content of existing industrial explosives tested in China is less than 130g, and the diameter of the charge is not greater than 45mm. It is measured after vacuuming in the cartridge, and the analysis of carbon monoxide and nitrogen oxides is carried out by chemical analysis methods. It can be seen that the existing devices cannot simulate the explosion environment of explosives under normal use conditions, thereby objectively reflecting the content of toxic gases produced after explosive explosions, and cannot meet the test conditions for large-dose, large-diameter charges of explosives without detonator sensitivity. Contents of the invention [0003] The present invention aims to solve one of the technical problems in the related art ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N25/54G01N30/02

CPCG01N25/54G01N30/02

Inventor 高玉刚翟廷海

Owner CHINA COAL TECH & ENG GRP HUAIBEIBLASTING TECHN RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com