Non-excavation drilling machine dragging tube and maintenance construction method thereof

A trenchless pipe-drawing technology, applied to pipes, rigid pipes, flange connections, etc., can solve the problems of inconvenient maintenance and use, inconvenient excavation of the soil layer, and difficulty in judging the damage position of the drag pipe, etc., to achieve the best results Better and convenient maintenance and replacement work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

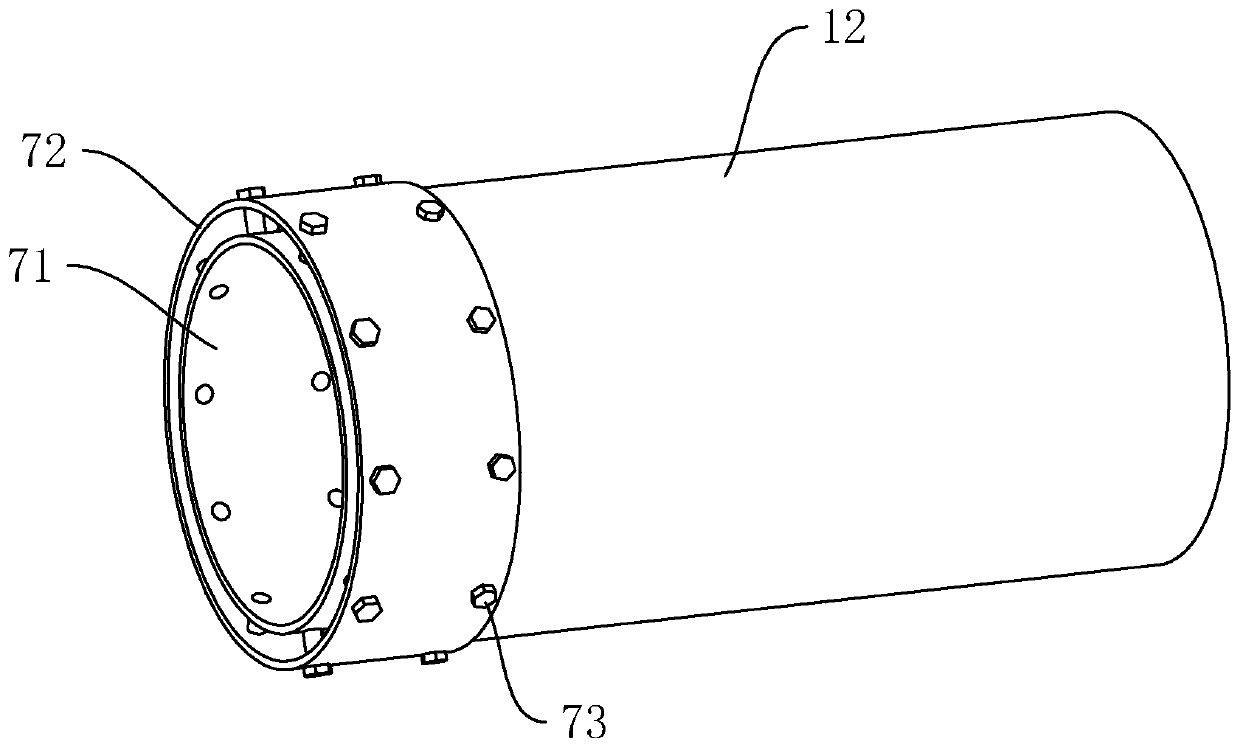

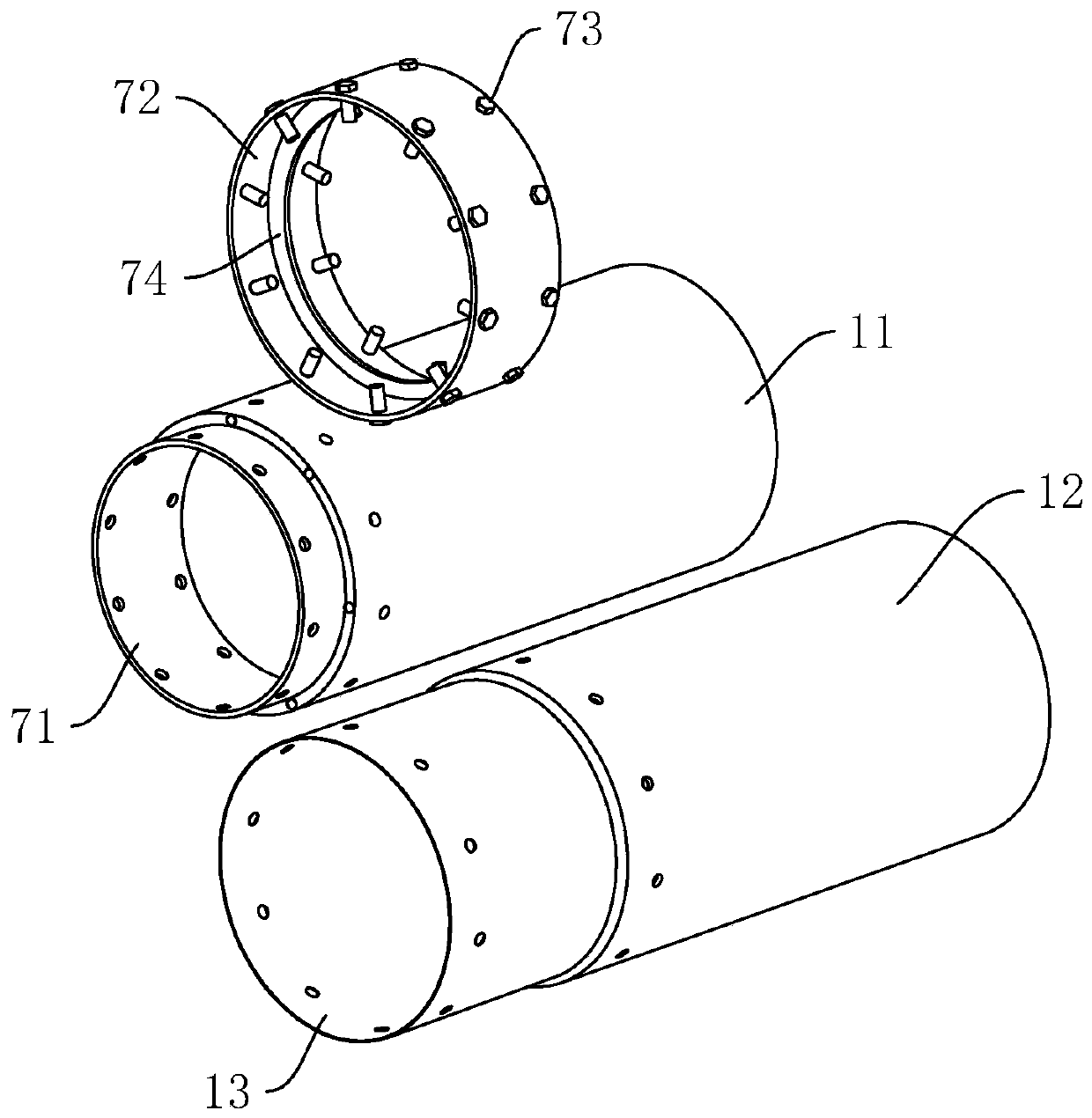

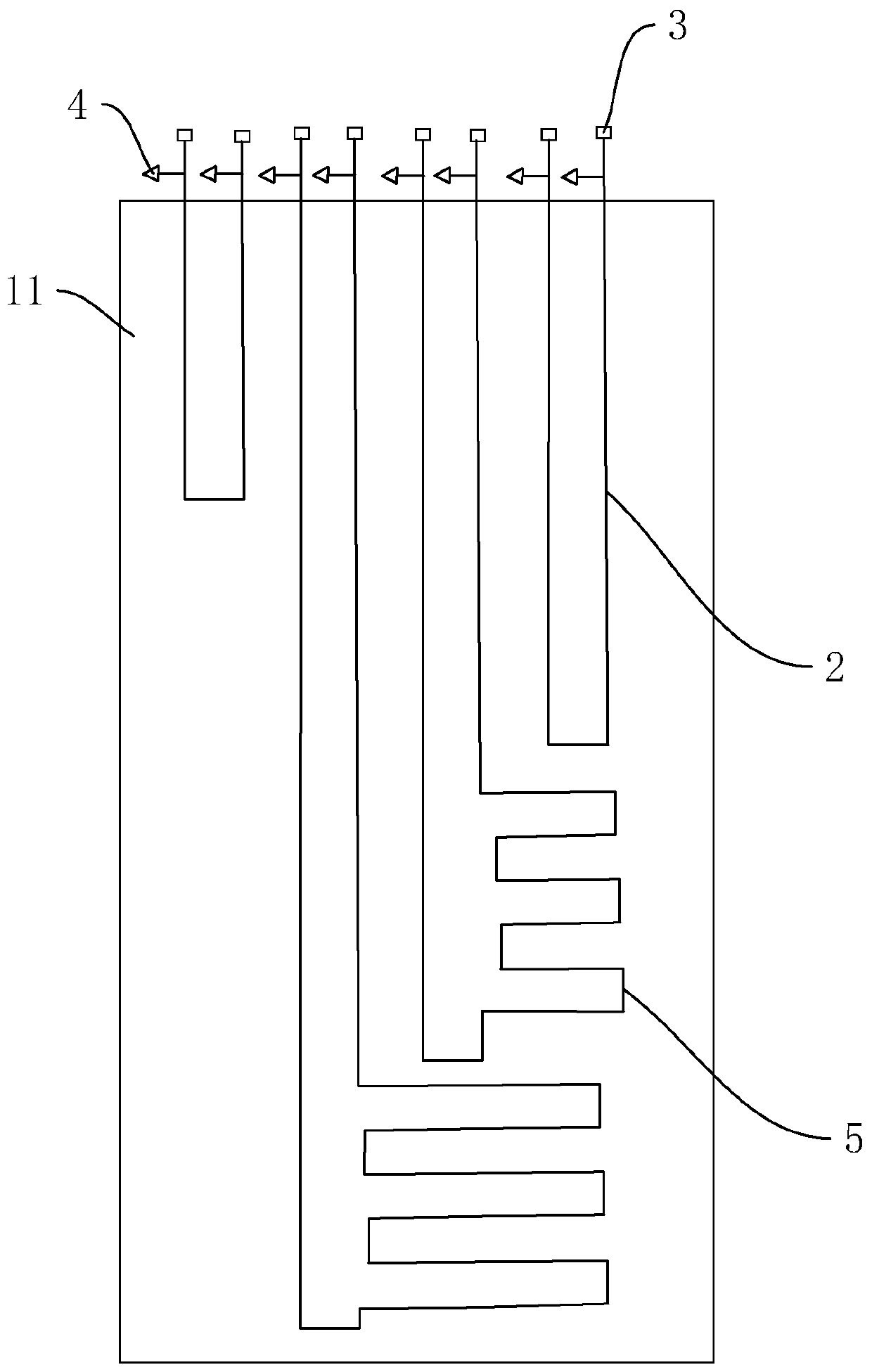

[0037] Trenchless drilling rig pull pipe, see figure 1 with figure 2 , including an inner tube 11 and an outer tube 12 coated and fixed outside the inner tube 11, a plurality of conductive wires 2 are arranged between the inner tube 11 and the outer tube 12, and the plurality of conductive wires 2 are distributed around the inner tube 11 in a circumferential direction . The reason why the conductive thread 2 is arranged between the inner tube 11 and the outer tube 12 is that an electric current needs to be passed on the conductive thread 2, and the damaged position of the drag tube can be judged by means of the electric current.

[0038] The inner tube 11 is made of insulating rubber, and a plurality of reinforcing wires 111 (marked on Figure 5 ); a plurality of reinforcing wires 111 are evenly distributed around the inner tube 11 in the circumferential direction, and metal wires can be selected.

[0039] The outer tube 12 is a wear-resistant tube, which can be made of FE...

Embodiment 2

[0057] The maintenance and construction method applied to the drag pipe of the non-excavation drilling rig, including:

[0058] Step 1. Obtain the damage information of the underground pipeline, delineate the area where the expected damage point is located, install protective fences and safety signs in the construction area, and move construction machinery, tools, and materials into the construction area;

[0059] Step 2. Determine the positions of the front and rear ends of the damaged pipeline according to the original pipeline layout drawings, and excavate them as pits No. 1 and No. 2;

[0060] Step 3: Workers enter the No. 1 pit or No. 2 pit, turn and disassemble the fixing bolt 73, so that the inner tube 11 and the outer tube 12 of another drag tube are no longer connected by the inner end of the drag tube end that needs to be repaired. The pipe 71 and the connecting pipe 72 at the outer end are clamped and fixed, and then the pulling pipe to be repaired and another pulli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com