Mounting method of fabricated bay window guardrail

An installation method and assembly technology, which is applied in the installation field of assembly bay window guardrails, can solve problems such as difficult to meet technical quality effect acceptance requirements, unsightly installation and formation of guardrails, unfavorable installation and formation of guardrails, etc., and shorten the installation period , Easy to install and disassemble, use performance, and improve the quality of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

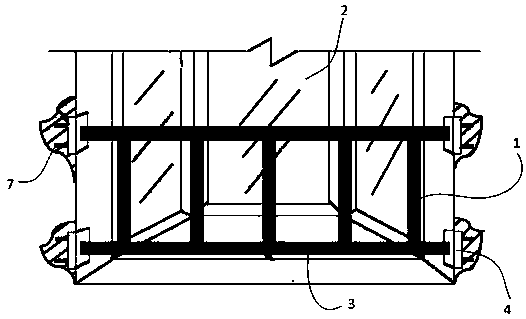

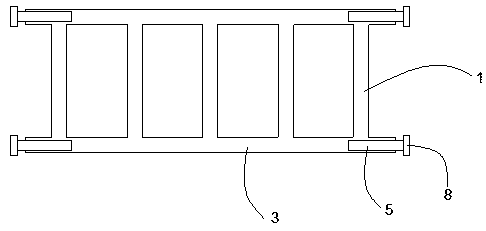

[0035] Embodiment 1: see Figure 1 to Figure 7 , a method for installing a prefabricated bay window guardrail, comprising the following steps:

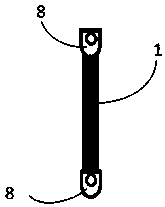

[0036] 1) According to the technical requirements, the guardrail 1 is made. The guardrail 1 includes two horizontal bars 3, and the two ends of the two bars 3 are respectively provided with a tenon 5, and the tenons 5 are far away from the sides of the bar 3. One side is provided with a clamping portion 8 extending vertically, and the end of the tenon 5 away from the clamping portion 8 is inserted into the inside of the cross bar 3 , and the tenon 5 and the cross bar 3 are fixedly connected.

[0037] 2) Make the pre-embedded installation component 4 , the pre-embedded installation component 4 has the hanging opening 6 corresponding to the tenon 5 .

[0038] 3) Installation process of the pre-embedded installation component 4: install the pre-embedded installation component 4 in a sunken way on the inner wall surface of the bay window...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com