Fabricated ceramic tile concrete composite board wall surface mounting system and method

A technology of installation system and composite board, applied in covering/lining, building, building structure, etc., can solve the problems of high cost, increased labor wages, long cycle, etc., achieve fast and efficient installation, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

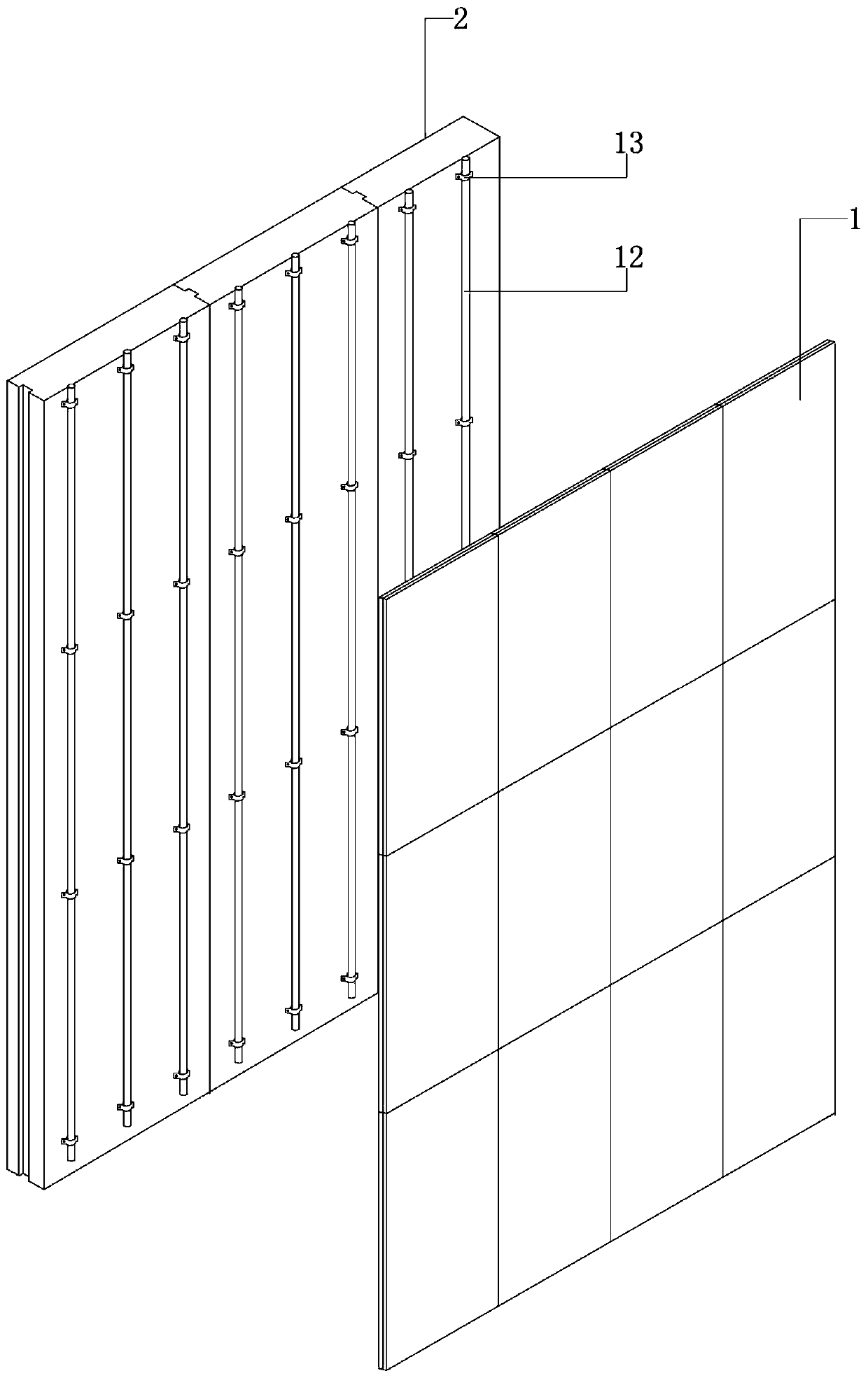

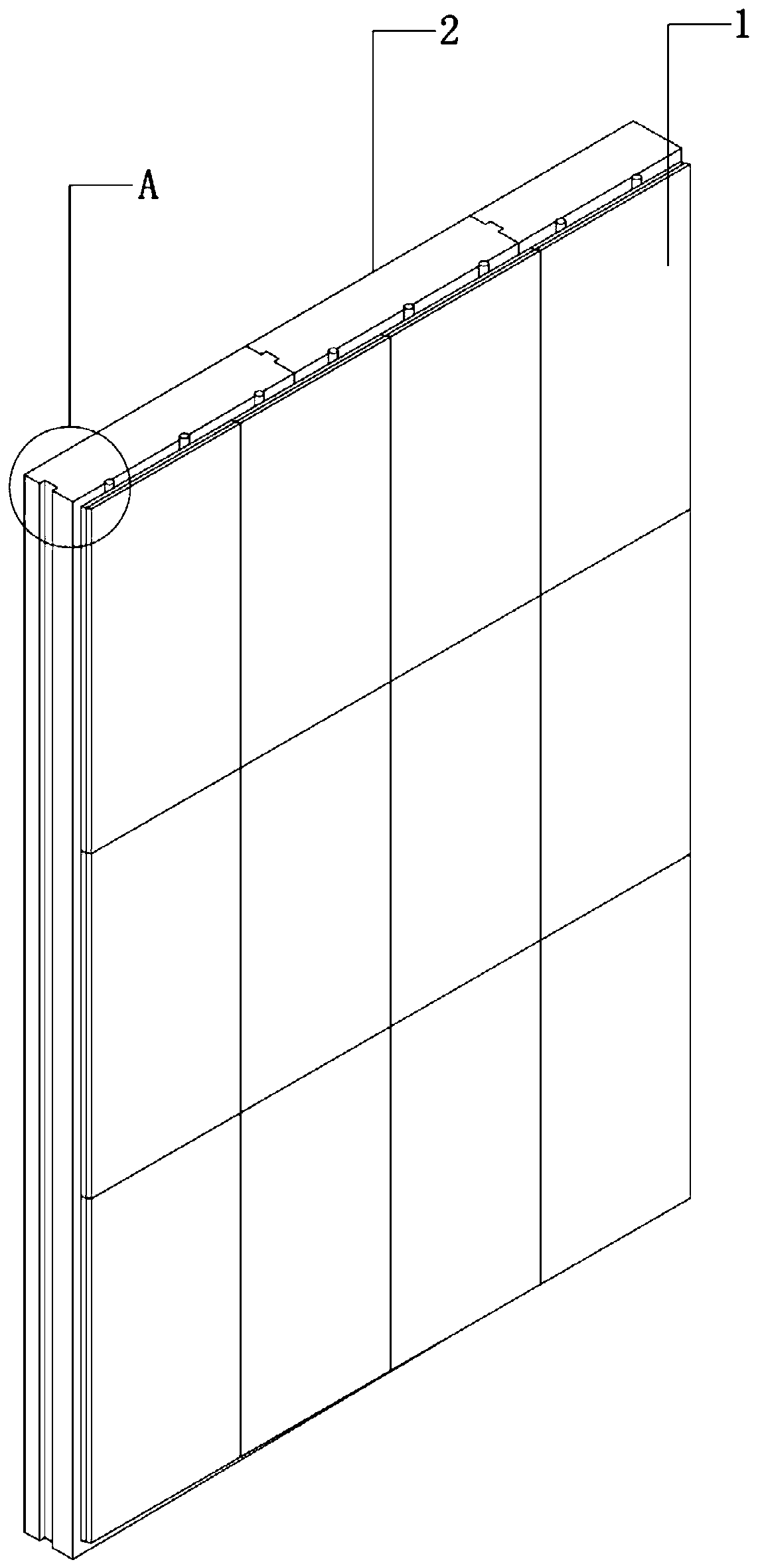

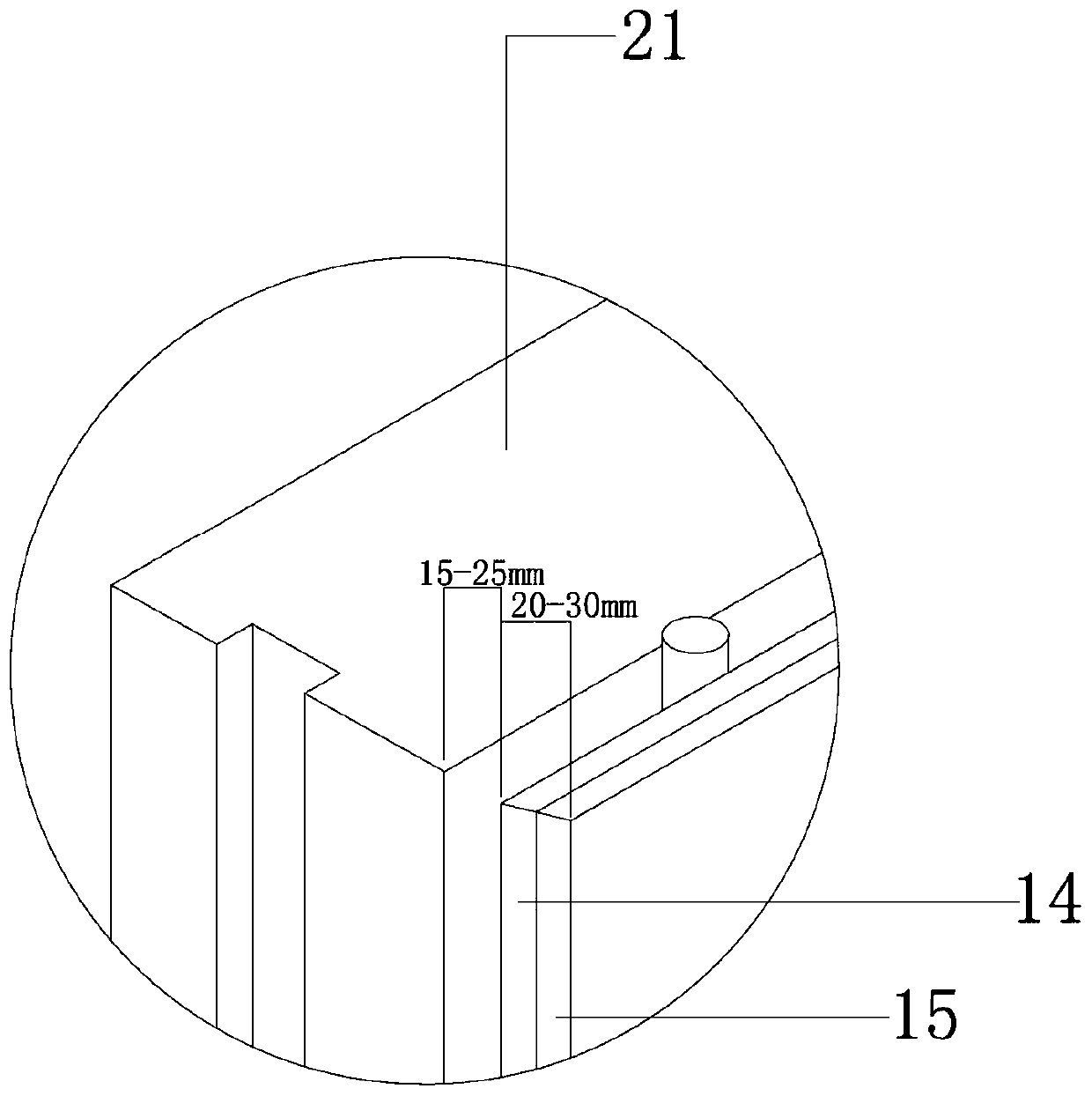

[0032] see Figure 1 to Figure 5 , the figure shows a prefabricated tile-concrete composite board wall installation system provided by Embodiment 1 of the present invention. The tile-concrete composite board 1 has a plurality of pipe clips 11 fixedly connected to its back, and the pipe clips 11 are arc-shaped. Opening pipe clip, there is a cavity for laying water and electricity pipelines between the tiled concrete composite board 1 and the wall body 2; it also includes a composite board connection mechanism, which includes a vertical metal pipe body and a pipe code 13, and the pipe clip 11 connects the tiled concrete composite board 1 is connected to the vertical metal pipe body 12, the vertical metal pipe body 12 is a round pipe; the vertical metal pipe body 12 is fixed on the wall body 2 by a plurality of pipe codes 13.

[0033] see Figure 1 to Figure 3 Specifically, the ceramic tile concrete composite board 1 includes a concrete base 14 and ceramic tiles 15 fixed on the ...

Embodiment 2

[0043] see Figure 1 to Figure 5 , the figure shows a prefabricated tile-concrete composite panel wall installation system provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The back side of the arc-shaped pallet is provided with a plurality of arc-shaped ribs 111 extending along the width direction of the arc-shaped pallet. The function is to form the strengthening effect of the clamping plate on the one hand, prevent the deformation of the clamping plate and affect the firmness of the clamping; on the other hand, when removing the floor veneer, use the ribs on the back to make the length of the clamping plate When one end of the pipe is separated from the pipe fitting first, the ribs can prevent the end from breaking when it is pulled up, so that the floor veneer can be easily removed while ensuring the strength.

Embodiment 3

[0045] see Figure 5 , the figure shows a prefabricated tile-concrete composite panel wall installation system provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The bottom of the wall body 2 is fixedly connected with a bottom supporting plate 22, which supports the bottom of the vertical metal pipe body 12, and the cross section of the bottom supporting plate 22 is Z-shaped. Through the setting of the above structure, the structure of the zigzag bottom supporting plate can prevent the deformation of the bottom of the pipe body (the top of the bottom supporting plate snaps into the inner side of the bottom of the vertical metal pipe body) to ensure the stability of the keel pipe structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com