A fast detection and judgment method for fdy network anomalies

A network anomaly and network wire technology, which is applied in the field of rapid detection and judgment of FDY network anomalies, can solve problems such as difficult to find anomalies, increase detection costs, and cannot effectively solve the abnormal phenomenon of fully drawn wire network, so as to ensure product quality, The effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

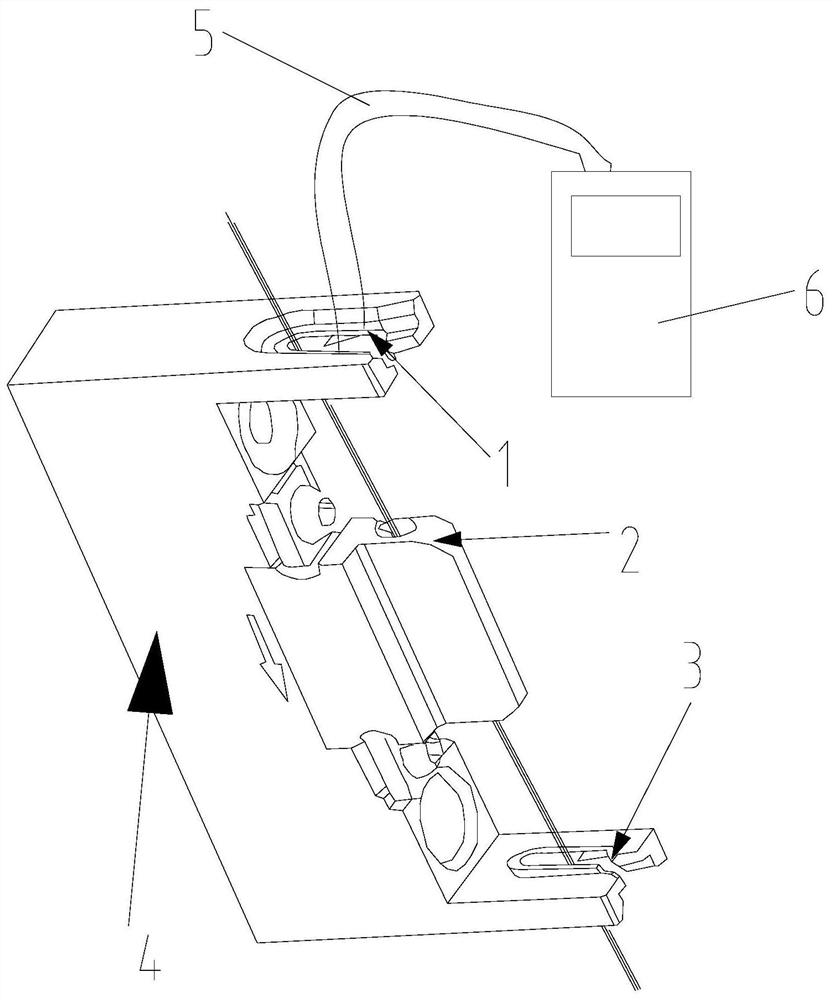

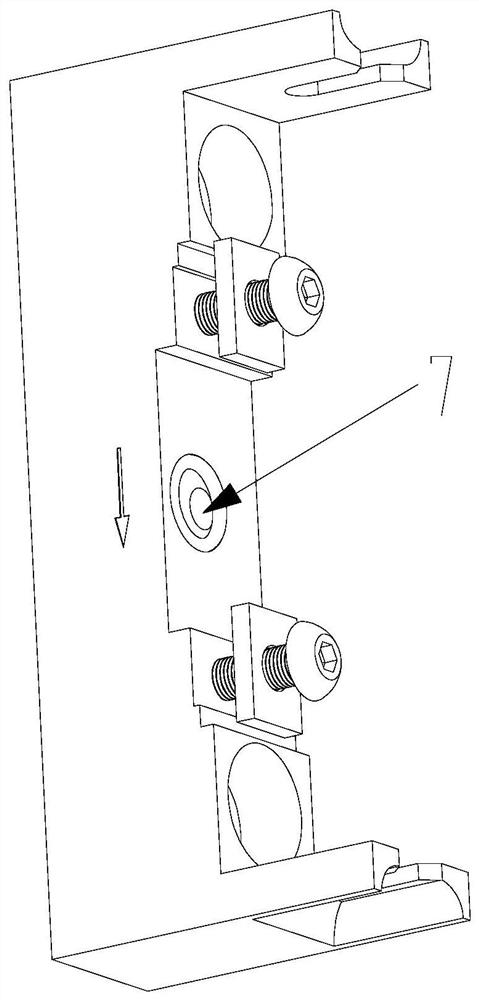

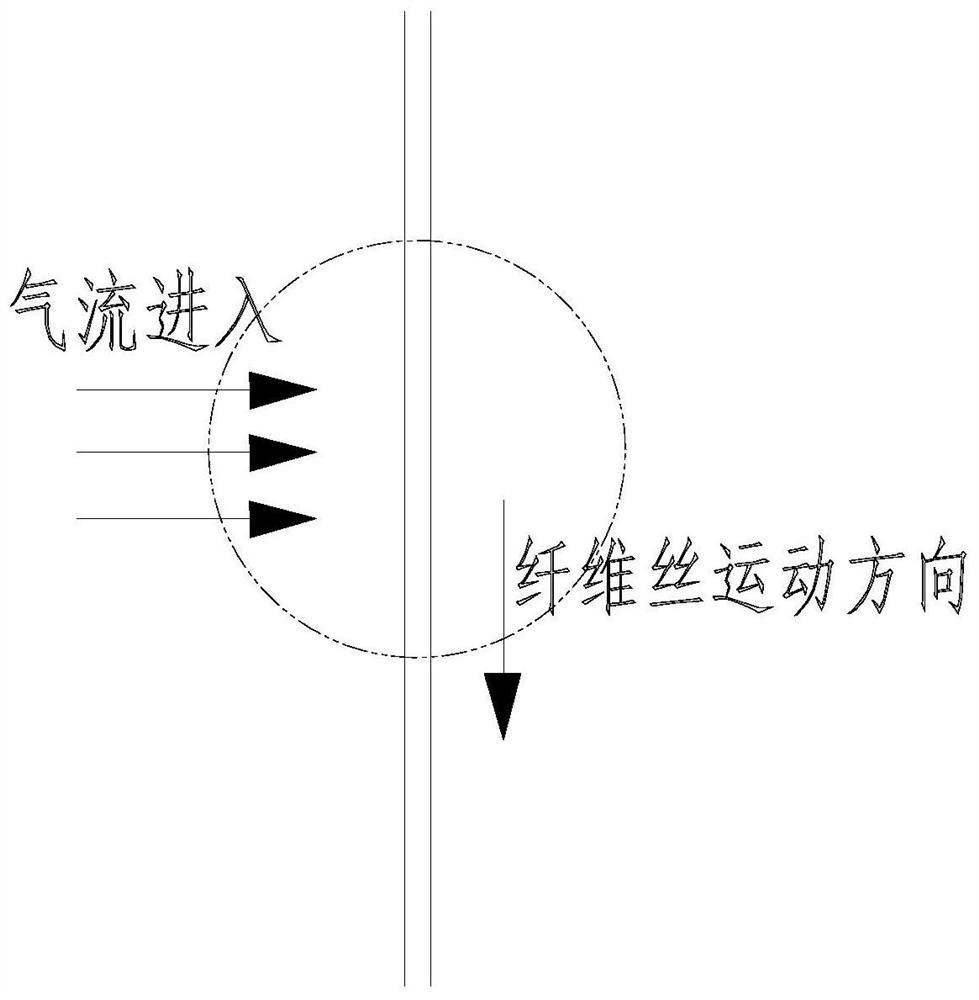

[0048] This example provides a method for detecting and judging network abnormalities in the production of fully drawn semi-dull polyethylene terephthalate fibers (semi-dull PET fibers). In the production of fully drawn yarns, under the action of airflow (the given pressure of semi-dull PET fiber is 0.37Mpa), make the many fiber filaments that pass through the first wire guiding device form the network filament bundle that has a plurality of network nodes in the network nozzle, then make described network filament The beam is processed after passing through the second wire guide device, and the detection and judgment method includes the following steps;

[0049] (1) Acquisition of pressure threshold

[0050] (i) by sequentially reducing the preset initial pressure value of the air flow, obtain the network tow to be inspected produced by the fully drawn yarn under each preset initial pressure value, and obtain each preset initial pressure value The test pressure value in the p...

Embodiment 2

[0062] This example provides a method for detecting and judging network anomalies in the production of fully drawn nylon 6 yarns. In the production of fully drawn yarns, under the action of airflow (the given pressure of nylon 6 is 0.35Mpa), the A plurality of filaments of a wire guide device form a network tow with a plurality of network nodes in the network nozzle, and then the network tow is processed after passing through a second wire guide device, and the detection and judgment method includes Follow the steps below;

[0063] (1) Acquisition of pressure threshold

[0064] (i) by sequentially reducing the preset initial pressure value of the air flow, obtain the network tow to be inspected produced by the fully drawn yarn under each preset initial pressure value, and obtain each preset initial pressure value The test pressure value in the production of fully drawn wire;

[0065] (ii) Carry out quality inspection sequentially on the network tow to be inspected obtained i...

Embodiment 3

[0076] This example provides a method for detecting and judging network anomalies in the production of full-drawn yarns of poly(trimethylene terephthalate) fibers (PTT fibers). Constant pressure is 0.3Mpa), make the many fiber filaments that pass through the first wire guide device form the network tow that has a plurality of network nodes in the network nozzle, then make described network tow pass through the second wire guide device After processing, the detection and judgment method includes the following steps;

[0077] (1) Acquisition of pressure threshold

[0078] (i) by sequentially reducing the preset initial pressure value of the air flow, obtain the network tow to be inspected produced by the fully drawn yarn under each preset initial pressure value, and obtain each preset initial pressure value The test pressure value in the production of fully drawn wire;

[0079] (ii) Carry out quality inspection sequentially on the network tow to be inspected obtained in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com